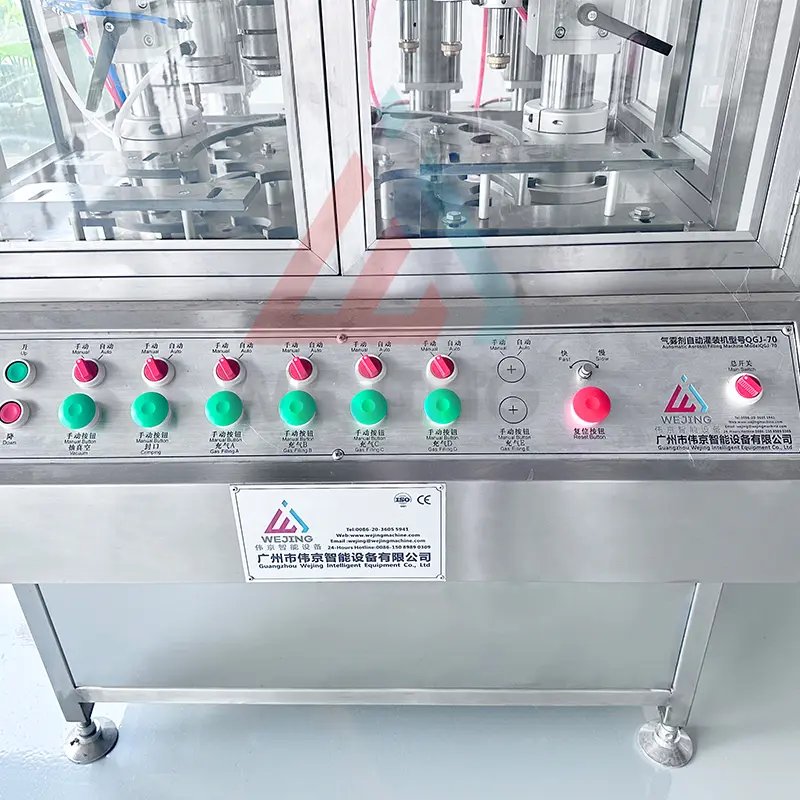

Cartridge Gas Aerosol Filling Machine

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Model Number |

QGJ70 |

|

Place of Origin |

Guangdong |

|

Certification |

CE&ISO9001 |

|

Supply Ability |

10sets per month |

|

Production speed |

60-70 cans / min |

|

Capacity |

30-750ml ( Can Be Customized) |

|

Speed |

High |

|

Gas consumption |

6.5m 3/ Min |

|

Dimension |

22000*3000*2000 mm |

Automatic Aerosol Filling MachineWork Process

1. Put the container into the vehicle.

2. Vacuum treat the container through a vacuum port to remove air impurities.

3. Perform sealing operation to ensure good sealing performance.

4. Four filling heads work simultaneously, injecting gas from the ink cartridge into the container to precisely control the filling volume.

5. Transport the loaded container to the next process.

2. Vacuum treat the container through a vacuum port to remove air impurities.

3. Perform sealing operation to ensure good sealing performance.

4. Four filling heads work simultaneously, injecting gas from the ink cartridge into the container to precisely control the filling volume.

5. Transport the loaded container to the next process.

1. High precision metering pumps are used for precise filling, ensuring smooth container transportation.

2. High degree of automation, accurate filling accuracy, convenient automation operation from bottle control, valves, sealing, filling to subsequent testing, packaging and other aspects, touch screen control.

3. Safe and reliable, equipped with various safety devices

4. Strong adaptability: It can be used to fill bundle gas containers of different specifications and shapes.

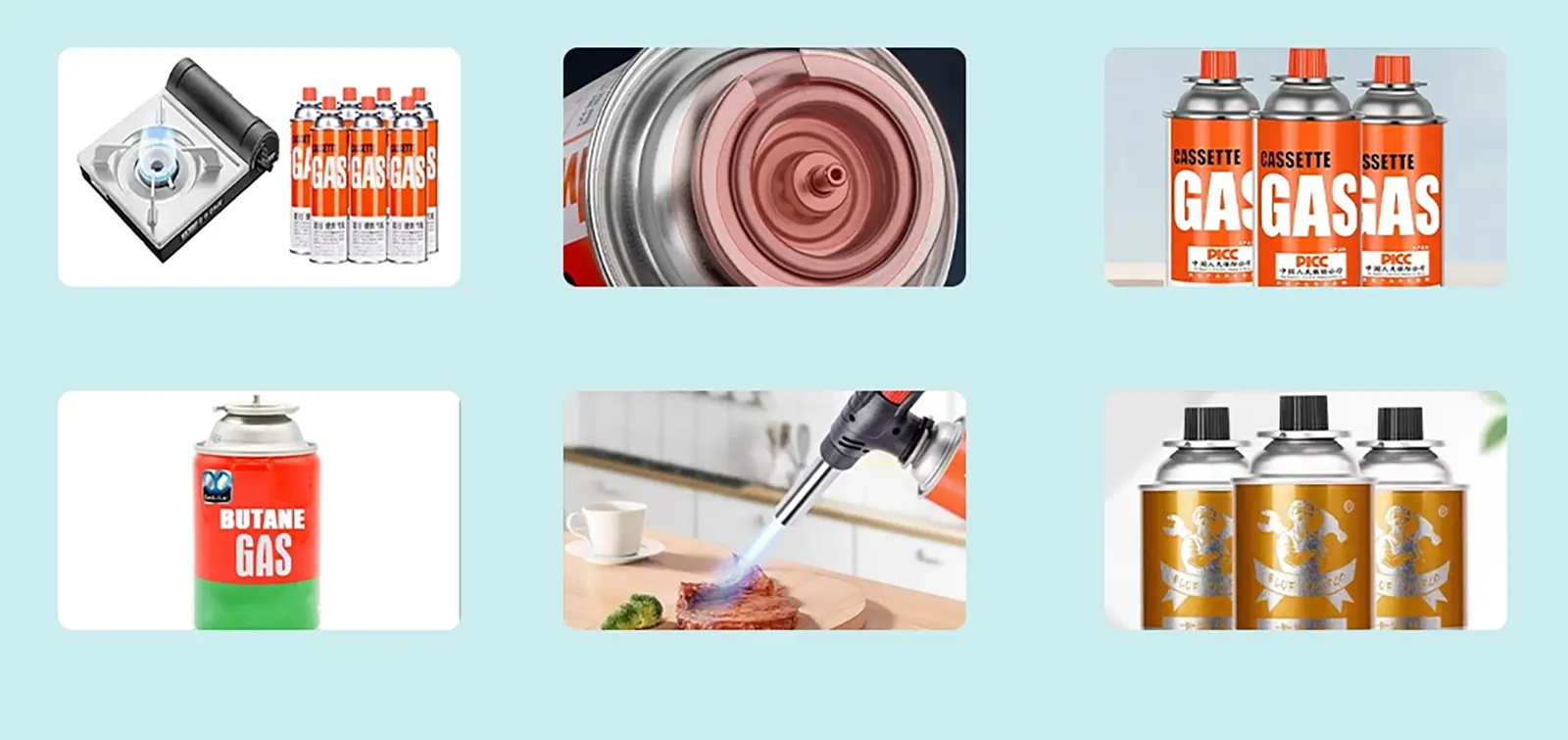

Product Applications

Box type gas spray can be used for portable gas stove to provide ignition source

After-sale Service

1.If the device malfunctions, we provide a 2-year warranty and free repairs.

2. Professional training, including operation and maintenance, to ensure customers use it correctly.

3. Regularly follow up to understand the operation of the equipment and promptly solve problems.

4. Quick troubleshooting response, remote guidance or door-to-door maintenance to ensure stable equipment operation.

2. Professional training, including operation and maintenance, to ensure customers use it correctly.

3. Regularly follow up to understand the operation of the equipment and promptly solve problems.

4. Quick troubleshooting response, remote guidance or door-to-door maintenance to ensure stable equipment operation.