Electric Aerosol Cans Weight Checker

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

≥ 120 bottles/min |

|

Transmission part |

reduction motor with variable frequency drive |

|

Installation |

The tool cabinet shall be installed under the platform, the door plate thickness shall be ≥ 1.5mm, and the handle shall be firm |

|

Size |

1600*1680*850mm |

|

Equipment sealing plate thickness |

≥ 1.5mm plate |

1.Reduce labor input and enhance product quality.

2.Weigh the cans prior to crimping to minimize losses.

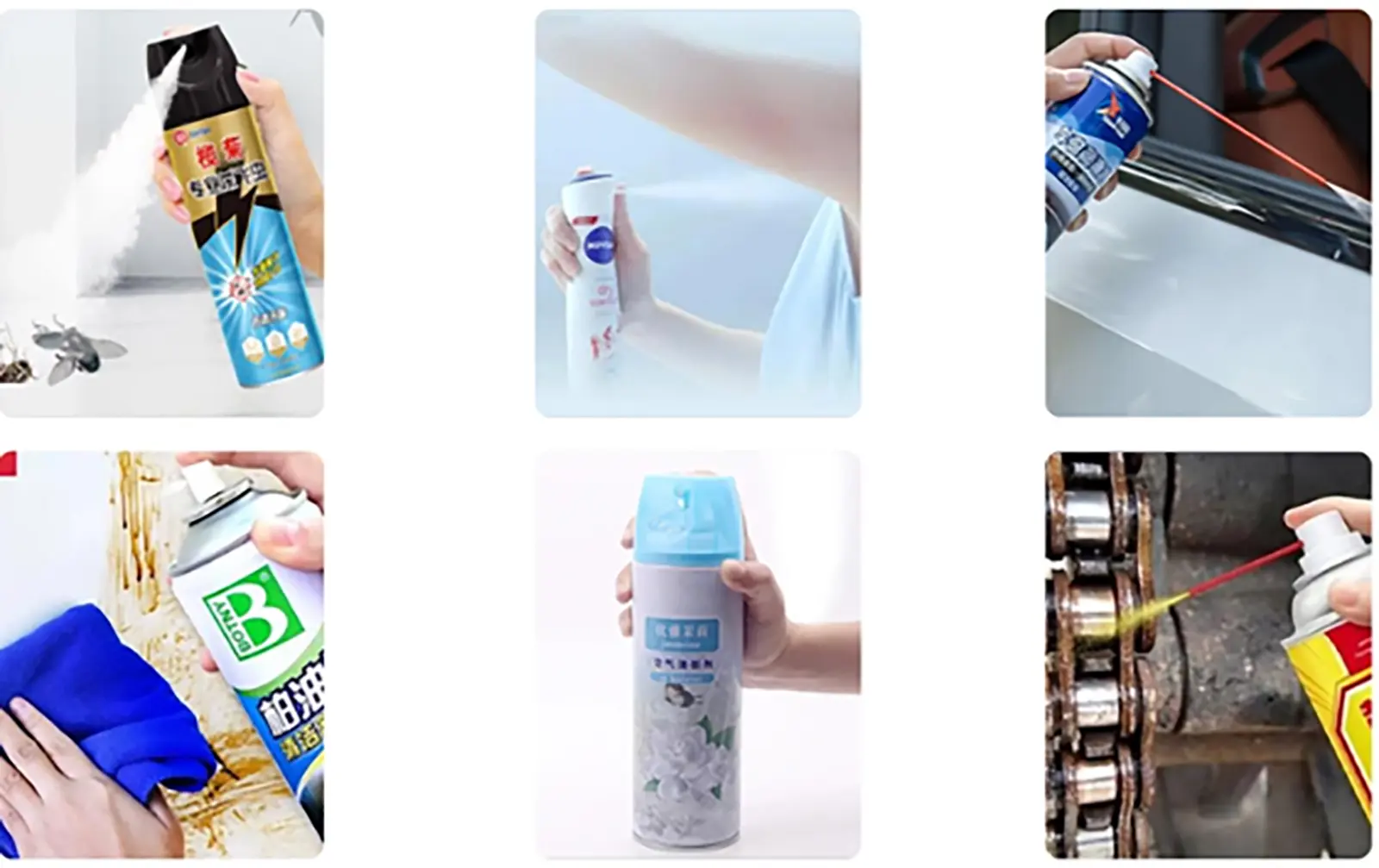

Product Applications

1. Conduct online weight inspection within aerosol production lines.

2. Manage quality during the manufacturing process.

3. Guarantee the consistent weight of aerosol cans.

4. Identify underfilled or overfilled cans.

5. Optimize production efficiency and cut down on waste.

2. Manage quality during the manufacturing process.

3. Guarantee the consistent weight of aerosol cans.

4. Identify underfilled or overfilled cans.

5. Optimize production efficiency and cut down on waste.

Product FAQ

1. What maintenance does the machine require?

Regular cleaning of the sensors and inspection of electrical connections. Lubrication of moving parts if applicable. Also, periodic calibration to maintain accuracy.

2. Does it have an alarm system for faulty cans?

Yes, it usually has an alarm that triggers when a can with an incorrect weight is detected. This can be an audible, visual, or both types of alarm.

3. Can it store weight data?

Some advanced models have data storage capabilities, allowing for record - keeping of weight measurements over time for quality analysis.

4. How does it integrate with the filling line?

It has interfaces and conveyor systems that can be synchronized with the aerosol filling line for seamless operation.

5. What is the power consumption of the machine?

Power consumption varies by model, but generally, it is designed to be energy - efficient within the range suitable for industrial production environments, typically consuming a few kilowatts per hour.

Regular cleaning of the sensors and inspection of electrical connections. Lubrication of moving parts if applicable. Also, periodic calibration to maintain accuracy.

2. Does it have an alarm system for faulty cans?

Yes, it usually has an alarm that triggers when a can with an incorrect weight is detected. This can be an audible, visual, or both types of alarm.

3. Can it store weight data?

Some advanced models have data storage capabilities, allowing for record - keeping of weight measurements over time for quality analysis.

4. How does it integrate with the filling line?

It has interfaces and conveyor systems that can be synchronized with the aerosol filling line for seamless operation.

5. What is the power consumption of the machine?

Power consumption varies by model, but generally, it is designed to be energy - efficient within the range suitable for industrial production environments, typically consuming a few kilowatts per hour.