Electronic Aerosol Cans Weight Checking Machine

1. Exceptional Precision: The Electronic Weight Checking Machine delivers exact gauging, guaranteeing stable filling of aerosol products and conforming to quality benchmarks.

2. Streamlined Functioning: Through its intuitive interface and convenient controls, the apparatus streamlines the weighing operation, cutting back on idle time and enhancing output.

3. Swift Adaptability: The machine can be promptly calibrated to fit diverse product parameters, affording versatility in production chains.

4. Dependability and Longevity: Fashioned to adhere to industrial norms, the Electronic Weight Checking Machine is engineered for enduring service, ensuring trustworthiness and curtailing upkeep expenses.

5. Sophisticated Surveillance: It presents instantaneous monitoring and data logging capabilities, permitting manufacturers to oversee production, spot latent problems, and take well-founded steps for process enhancement.

2. Streamlined Functioning: Through its intuitive interface and convenient controls, the apparatus streamlines the weighing operation, cutting back on idle time and enhancing output.

3. Swift Adaptability: The machine can be promptly calibrated to fit diverse product parameters, affording versatility in production chains.

4. Dependability and Longevity: Fashioned to adhere to industrial norms, the Electronic Weight Checking Machine is engineered for enduring service, ensuring trustworthiness and curtailing upkeep expenses.

5. Sophisticated Surveillance: It presents instantaneous monitoring and data logging capabilities, permitting manufacturers to oversee production, spot latent problems, and take well-founded steps for process enhancement.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Allowance |

≤±1g |

|

Max. weight |

0-1500g |

|

Capacity |

60-70cans/min |

|

Working pressure |

0.5MPa |

|

Suitable can diameter |

35-73mm |

|

Suitable can height |

90-330mm |

|

Power |

AC220V/50HZ |

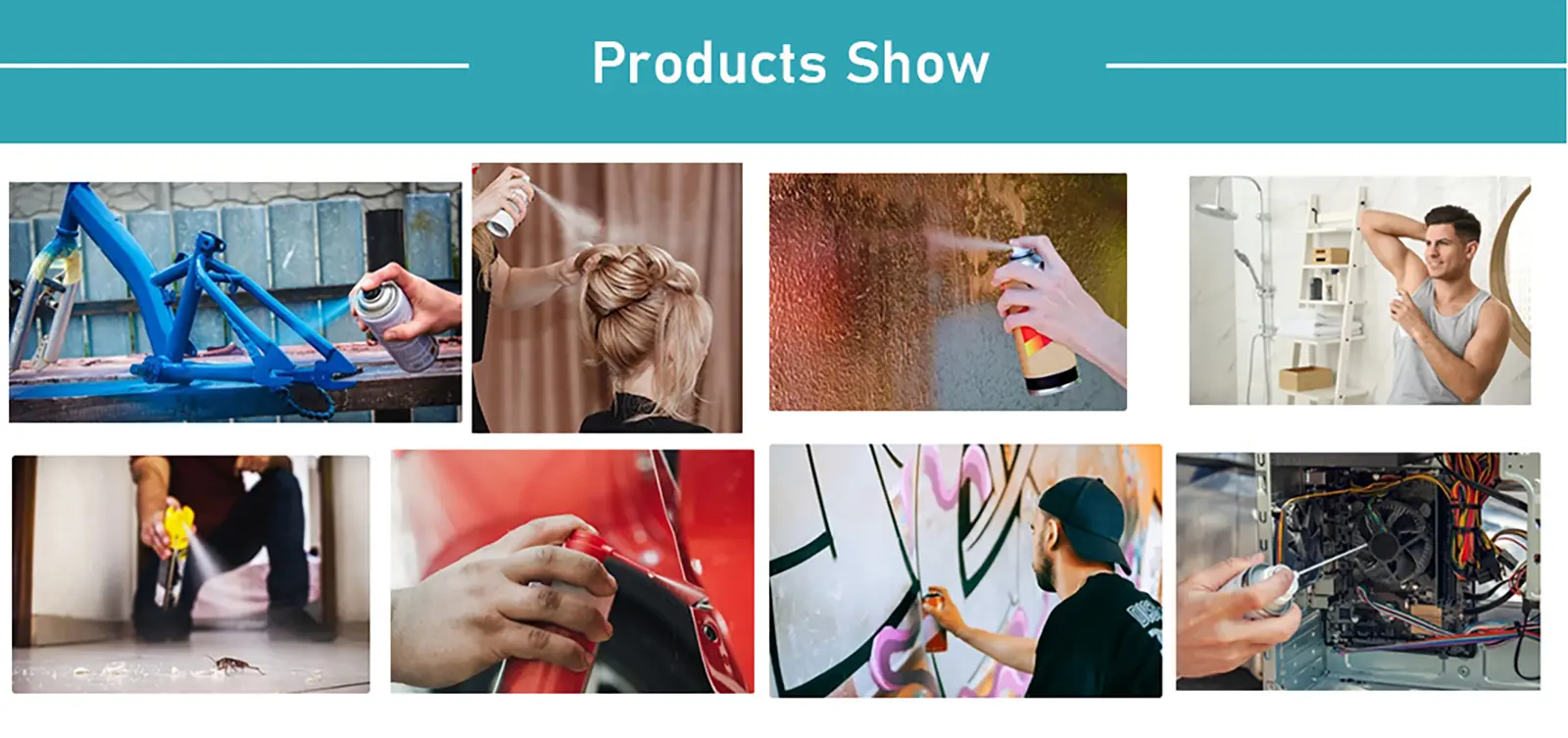

Product Applications

1. Weight and Fill Operation: Utilize highly sophisticated techniques to meticulously measure and fill aerosol products, thereby ensuring the utmost precision in dosage.

2. Quality Management Aspect: Actively contribute to the maintenance of consistent product weights and the attainment of top-notch quality.

3. Production Data Tracking: Rigorously monitor and record production data to facilitate the optimization of process control.

4. Adjustment and Calibration Steps: Expedite the process of rapid adjustments and calibrations to accommodate various product specifications.

5. Compliance Assurance: Stringently adhere to weight regulations and standards to guarantee complete compliance.

2. Quality Management Aspect: Actively contribute to the maintenance of consistent product weights and the attainment of top-notch quality.

3. Production Data Tracking: Rigorously monitor and record production data to facilitate the optimization of process control.

4. Adjustment and Calibration Steps: Expedite the process of rapid adjustments and calibrations to accommodate various product specifications.

5. Compliance Assurance: Stringently adhere to weight regulations and standards to guarantee complete compliance.

Product FAQ

1. How accurate is the machine?

It offers high accuracy, often within ± 0.1 grams. This ensures precise weight measurement of aerosol cans, crucial for quality control and meeting production standards.

2. Can it adapt to various can sizes?

Yes, it's adjustable. It can handle different diameter and height aerosol cans, making it suitable for diverse product lines and saving on equipment costs.

3. What's its weight checking speed?

The speed varies. Generally, it can check dozens of cans per minute. Some models can reach up to 70 cans/minute, ensuring efficient production without sacrificing accuracy.

4. What data output does it give?

It provides individual can weights and statistics like average weight and standard deviation. Data can be shown on display or exported for further analysis and quality control.

5. Is maintenance difficult?

No. It has accessible parts for easy cleaning and replacement. Simple tasks like sensor calibration and connection checks are involved. Manuals and tech support assist with complex issues.

It offers high accuracy, often within ± 0.1 grams. This ensures precise weight measurement of aerosol cans, crucial for quality control and meeting production standards.

2. Can it adapt to various can sizes?

Yes, it's adjustable. It can handle different diameter and height aerosol cans, making it suitable for diverse product lines and saving on equipment costs.

3. What's its weight checking speed?

The speed varies. Generally, it can check dozens of cans per minute. Some models can reach up to 70 cans/minute, ensuring efficient production without sacrificing accuracy.

4. What data output does it give?

It provides individual can weights and statistics like average weight and standard deviation. Data can be shown on display or exported for further analysis and quality control.

5. Is maintenance difficult?

No. It has accessible parts for easy cleaning and replacement. Simple tasks like sensor calibration and connection checks are involved. Manuals and tech support assist with complex issues.