Full Auto BOV Aerosol Filling Line

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Filling capacity (cans/min) |

45-60cans/min |

|

Liquid filling volume (ml) |

10-300ml/head |

|

Gas filling accuracy |

≤±1% |

|

Liquid filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35-70 ( can be customized) |

|

Applicable cans height (mm) |

70-300 ( can be customized) |

|

Applicable valve (mm) |

25.4 (1 inch) |

|

Propellant |

N2, compressed air |

|

Max gas consumption (m3/min) |

6m3/min |

|

Power (KW) |

AC 380V/50HZ |

|

Air source |

0.6-0.7Mpa |

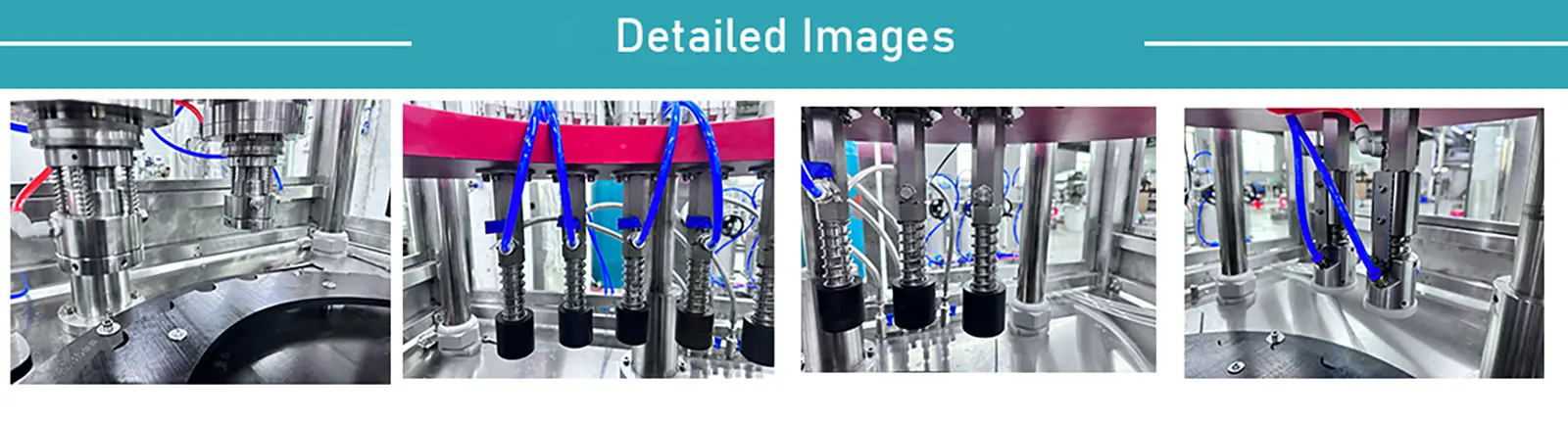

1. Inflatable head: There are two inflatable heads that can quickly inflate and seal the container. Ensure that the aerosol is in a suitable pressure state in the container before filling, providing a good foundation for subsequent filling and other processes.

2. Infusion head: Equipped with six infusion heads, it can perform infusion operations at a high speed. The filling volume can be adjusted between 30-1200ml to meet the needs of different specifications of products.

2. Infusion head: Equipped with six infusion heads, it can perform infusion operations at a high speed. The filling volume can be adjusted between 30-1200ml to meet the needs of different specifications of products.

3. Pressure gauge: Two pressure gauges can be used to detect the pressure of the filled aerosol container, ensuring the safety and stability of the product.

4. Cleaning hair: Used to clean aerosol cans during the production process to ensure their cleanliness and hygiene.

4. Cleaning hair: Used to clean aerosol cans during the production process to ensure their cleanliness and hygiene.

Product Advantages

1. Efficient production: The high-speed filling capacity and multi station design greatly improve production efficiency.

2. Precise filling: Accurate filling volume control ensures stable product quality.

3. High degree of automation: reduces manual operations, lowers production costs, and improves production safety.

4. Multi functional integration: Integrating functions such as inflation, liquid filling, pressure measurement, and cleaning into one, saving space and equipment investment.

5. Easy to operate: The equipment adopts an advanced control system, which is easy to operate and maintain.

2. Precise filling: Accurate filling volume control ensures stable product quality.

3. High degree of automation: reduces manual operations, lowers production costs, and improves production safety.

4. Multi functional integration: Integrating functions such as inflation, liquid filling, pressure measurement, and cleaning into one, saving space and equipment investment.

5. Easy to operate: The equipment adopts an advanced control system, which is easy to operate and maintain.

PRODUCT Applications

The fully automatic binary gas filling line is suitable for filling various products. In the industrial sector, it can be filled with fire extinguisher propellants, refrigeration equipment refrigerants, etc. The medical field is suitable for filling specific medical aerosols. Cosmetic spray that can be filled with binary packaging in the daily chemical field, such as moisturizing spray, makeup setting spray, etc. There are also products such as industrial cleaning agents and foaming agents that use binary packaging.

After Sales Service

1. The fully automatic binary aerosol filling line provides comprehensive and high-quality after-sales service.

During the two-year warranty period, free maintenance and replacement of parts damaged due to quality issues will be provided,

3. A professional team responds quickly, with dedicated personnel providing guidance and training for installation and debugging.

4. Provide 24/7 online consultation to solve technical problems at any time.

During the warranty period, regular maintenance, including cleaning and other services, can be provided as needed to extend the lifespan of the equipment.

6. We have a comprehensive accessory supply system and offer discounted original factory accessories outside the warranty period.

7. With customer satisfaction as the core, regularly follow up to improve services, and humbly accept opinions and suggestions.

During the two-year warranty period, free maintenance and replacement of parts damaged due to quality issues will be provided,

3. A professional team responds quickly, with dedicated personnel providing guidance and training for installation and debugging.

4. Provide 24/7 online consultation to solve technical problems at any time.

During the warranty period, regular maintenance, including cleaning and other services, can be provided as needed to extend the lifespan of the equipment.

6. We have a comprehensive accessory supply system and offer discounted original factory accessories outside the warranty period.

7. With customer satisfaction as the core, regularly follow up to improve services, and humbly accept opinions and suggestions.