Glass Bead Inserted Machine For Aerosols

1. Efficient operation: The automatic glass bead machine automates the process of distributing glass beads onto the surface, greatly improving productivity, reducing manual labor, and saving time.

2. Accurate and consistent application: This machine adopts advanced technology to ensure the precise and consistent application of glass beads, thereby forming uniform and high-quality road markings or reflective surfaces.

3. Widely applicable: This machine is suitable for various applications, including road markings, airport runway markings, parking lots, and safety signs, providing flexibility and versatility for different projects.

4. Enhance safety: The automatic glass bead machine ensures the correct and uniform distribution of glass beads, improves the visibility and reflectivity of markings, thereby enhancing road safety for drivers and pedestrians.

5. Cost effective solution: By automating the glass bead application process, this machine reduces material waste and labor costs, providing an economically efficient solution for road marking and other applications.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

60-70 cans /min |

|

Suitable can height |

70-330mm |

|

Suitable can diameter |

35-70mm |

|

Control |

Pneumatic control |

|

Air source |

0.8Mpa |

|

Size |

1900*1700*850mm |

|

Weight |

300kg |

|

Ball filling quantity |

2 pcs/time(can be customized) |

|

Speed |

50-70cpm |

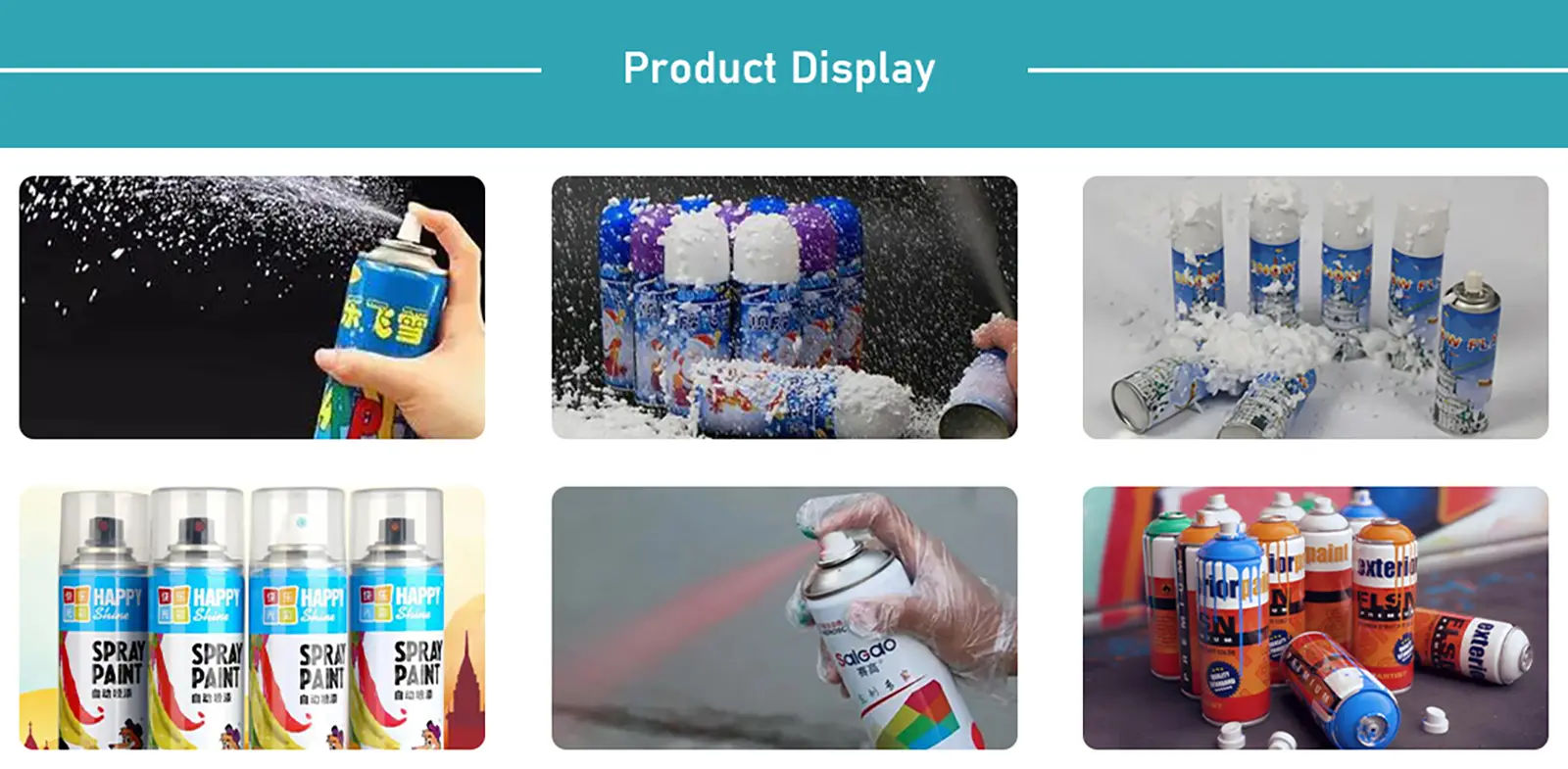

product Applications

2. When decorating homes, this filling line can be used to fill decorative spray paint, making it easy to handle both furniture renovation and wall creation.

3.In the industrial manufacturing process, it is used for industrial spray painting and filling, ensuring stable quality and improving industrial production efficiency.

4. In artistic creation occasions, it is suitable for art spray painting and filling, and the use of glass bead machines allows artists to better present their creativity.

product faq

A: Yes, the machine is designed to accommodate glass beads of various sizes, providing flexibility for different applications and requirements.

A: Regular maintenance includes cleaning the machine after use, inspecting and replacing any worn parts, and ensuring proper lubrication to ensure smooth operation. For specific maintenance instructions, please refer to the manufacturer's guide.