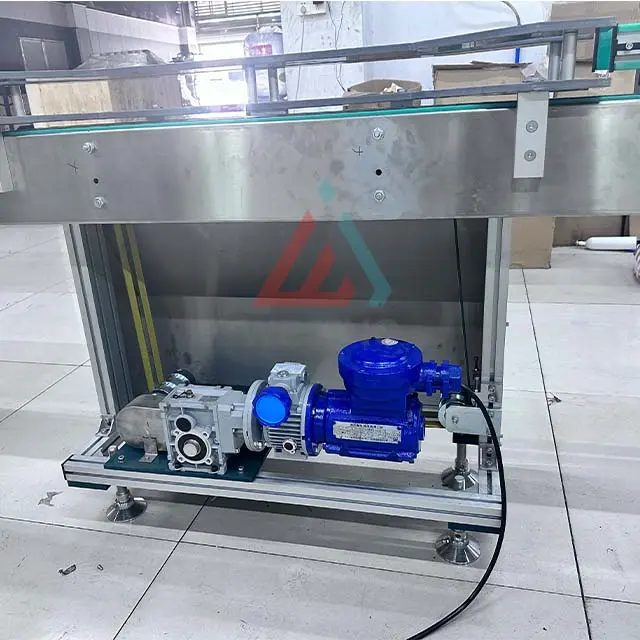

Inkjet Conveyor for Aerosol Cans

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Speed |

>120 bottles /min |

|

Thickness |

1000x360x850 mm aluminum profile frameside plate 10mm thick iron plate plasticsprayig treatment |

|

Power |

0.18kW/380VAC |

|

Applicable aerosolcan diameter |

35-70mm |

|

Applicable aerosol can height |

80-300 mm |

|

Coding width |

15mm |

|

Size |

1000*360*850mm |

1. Enhanced Productivity: Our inkjet printing conveyor belt speeds up aerosol filling, cutting production time and increasing output, optimizing overall operations.

2. Impeccable Accuracy: It ensures uniform, detailed inkjet application for clear labels, boosting product recognition and easy tracing.

3. Mobility & Adaptability: Highly mobile, this conveyor can be easily moved and configured to fit various manufacturing setups.

2. Impeccable Accuracy: It ensures uniform, detailed inkjet application for clear labels, boosting product recognition and easy tracing.

3. Mobility & Adaptability: Highly mobile, this conveyor can be easily moved and configured to fit various manufacturing setups.

4. Space-Saving Design: Its compact design fits existing layouts, maximizing space and minimizing disruption.

5. Reliable Performance: Made of premium materials and advanced tech, it's reliable, reducing downtime and ensuring long-term productivity.

5. Reliable Performance: Made of premium materials and advanced tech, it's reliable, reducing downtime and ensuring long-term productivity.

PRODUCT Applications

1. Accurate Identification & Tracing: Our inkjet conveyor belt is customized for precision, playing a crucial role in applying highly accurate inkjet prints that are essential for differentiating labels and enabling efficient batch tracking on aerosol containers.

2. Clear Display of Product Information: It enables the sharp and legible reproduction of important details - such as product names, ingredient lists, usage instructions, and expiration dates - right onto aerosol packaging.

3. Custom Brand Boost: Our conveyor simplifies personalization and strengthens brands, allowing businesses to enhance brand visibility by adding printed logos and eye-catching visuals.

4. Compliance with Regulations: As a key element in meeting industry regulations, our inkjet conveyor ensures adherence to legal requirements through reliable and consistent printing practices for necessary disclosures.

5. Guarantee of High Quality: It plays a vital part in maintaining quality standards, assuring accurate and consistent printing results. This reduces the risk of errors or mislabeling, thus improving product quality and customer satisfaction.

Operation Guide

1. Installation & Sync: Follow manufacturer's install & safety guides. Securely fasten and sync inkjet conveyor belt with aerosol filling equipment.

2. Velocity Adjustment: Adjust conveyor speed to match production flow. Ensure smooth container movement for optimal inkjet application.

3. Printer Setup: Configure inkjet printer per print specs: font size, content layout, position. Aim for clear prints on each bottle.

4. Bottle Placement: Place aerosol bottles evenly spaced and correctly oriented on conveyor for efficient printing.

5. Monitoring & Fix: Monitor printing process. Regularly check print clarity & alignment. Adjust as needed to enhance results.

2. Velocity Adjustment: Adjust conveyor speed to match production flow. Ensure smooth container movement for optimal inkjet application.

3. Printer Setup: Configure inkjet printer per print specs: font size, content layout, position. Aim for clear prints on each bottle.

4. Bottle Placement: Place aerosol bottles evenly spaced and correctly oriented on conveyor for efficient printing.

5. Monitoring & Fix: Monitor printing process. Regularly check print clarity & alignment. Adjust as needed to enhance results.