Laboratory 10L Homogenizer Machine

Vacuum Emulsifying MixerPRODUCT PARAMETERS

|

Model |

Capacity(L) |

Mixing |

Homogenizing |

||

|

Power(kw) |

Speed(r/min) |

Power(kw) |

Speed(r/min) |

||

|

WJ-LBR10 |

10 |

0.37 |

0-63 |

1.5 |

0-6000 |

|

WJ-LBR50 |

50 |

0.75 |

0-63 |

3 |

0-6000 |

|

WJ-LBR100 |

100 |

1.5 |

0-63 |

4 |

0-6000 |

|

WJ-LBR200 |

200 |

2.2 |

0-63 |

5.5 |

0-6000 |

|

WJ-LBR300 |

300 |

3 |

0-63 |

7.5 |

0-6000 |

|

WJ-LBR500 |

500 |

4 |

0-63 |

11 |

0-6000 |

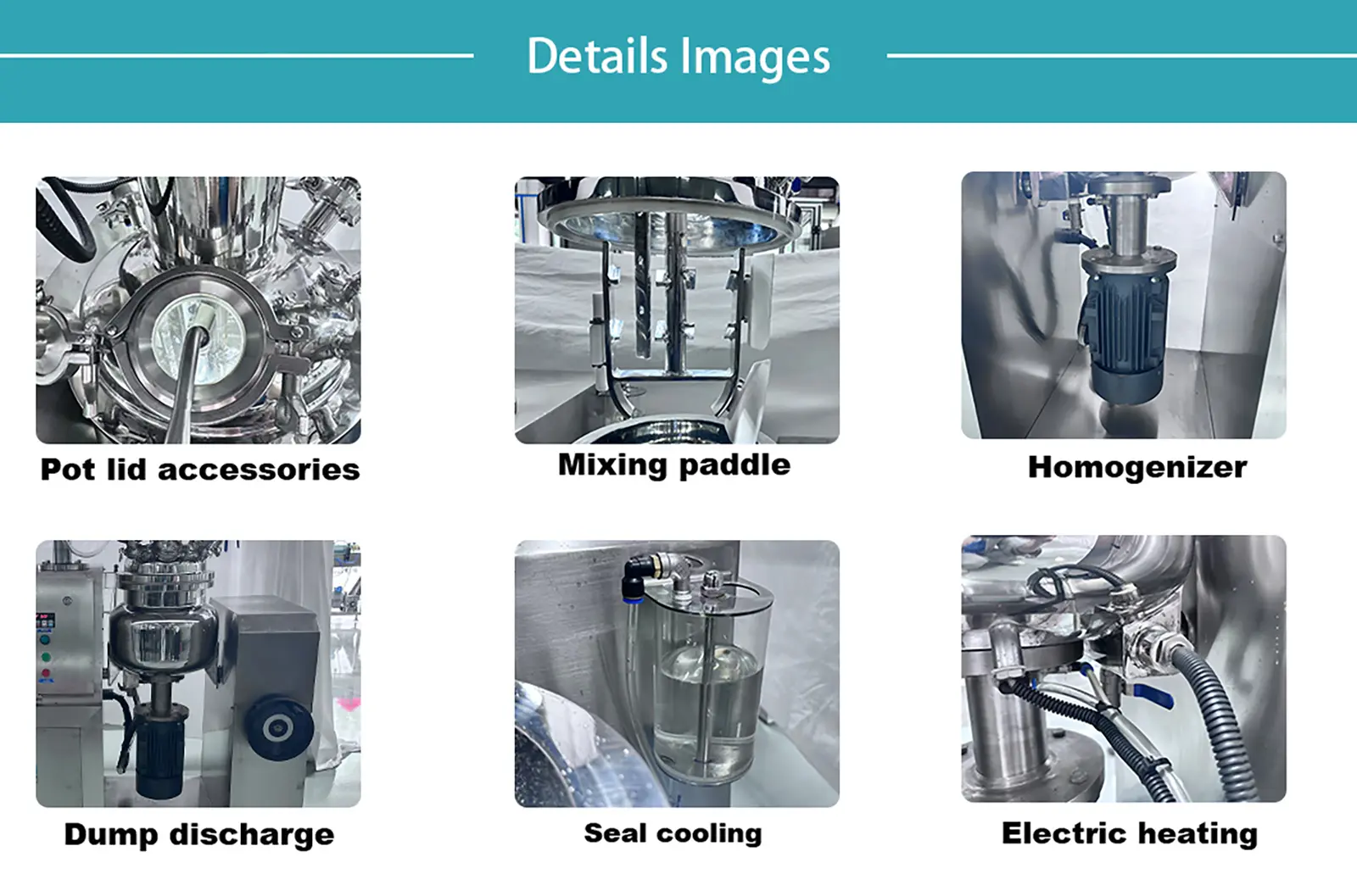

1. Lifting system: The pot lid can be lifted and lowered freely within this system. This enables easy operation and cleaning, and also simplifies the process of putting in and taking out materials.

2. Vacuum system: A vacuum environment can be created by this system. During processing, this prevents bubbles from mixing with the material, thereby enhancing the product's fineness and stability.

3. Mixing system: Commonly, this system employs multiple mixing approaches and supports variable - frequency speed regulation. This allows it to fulfill the production demands of various processes.

4. Homogenization system: This system is the equipment's core. It can effectively shear, crush, and emulsify materials to achieve a homogeneous state.

5.Tank body: Constructed from high - quality stainless steel materials such as SUS304 or SUS316L, the tank body and pipes are mirror - polished. This complies with GMP standards, guaranteeing the equipment's hygiene and safety.

2. Vacuum system: A vacuum environment can be created by this system. During processing, this prevents bubbles from mixing with the material, thereby enhancing the product's fineness and stability.

3. Mixing system: Commonly, this system employs multiple mixing approaches and supports variable - frequency speed regulation. This allows it to fulfill the production demands of various processes.

4. Homogenization system: This system is the equipment's core. It can effectively shear, crush, and emulsify materials to achieve a homogeneous state.

5.Tank body: Constructed from high - quality stainless steel materials such as SUS304 or SUS316L, the tank body and pipes are mirror - polished. This complies with GMP standards, guaranteeing the equipment's hygiene and safety.

Product Advantages

1. Efficiency:

This equipment can swiftly homogenize and emulsify materials, thereby ramping up production efficiency. It's like a productivity booster in the production process.

2. High quality:

The resultant products feature tiny particle size, consistent texture, an exquisitely delicate luster, along with remarkable stability and ductility. They are the epitome of high - grade quality.

3. Multifunctionality:

It brings together various functions such as vacuum defoaming, stirring, homogenization, heating, and electrical control. It's a multifaceted tool that can fulfill a wide array of process demands with ease.

4. Easy to operate:

Operating this device is a breeze. It's simple to control and offers excellent stability and reliability. You don't need to be an expert to handle it.

5. Health and Safety:

It adheres to GMP standards, providing a solid safeguard for the hygiene and safety of the product. It's like a reliable guardian in the production environment.

Product Applications

The 10L lifting homogenizer is mainly used in industries such as cosmetics, food, pharmaceuticals, and chemicals. It can efficiently homogenize lotion, soy sauce, ointment, paint, etc., with moderate capacity, flexible lifting, convenient operation, convenient cleaning, and can improve product quality and stability.