Manual Aerosol Filling Crimping Machine

Automatic Aerosol Filling MachinePRODUCT ADVANTAGES

1. This machine boasts high filling precision and consistency. It guarantees that every single container gets filled precisely with the exact quantity of the product, leaving no room for errors in the filling process.

2. The operation of it is straightforward. Operators don't need extensive training to understand and handle the machine. They can quickly get the hang of it and start operating it smoothly in a short period.

3. It shows great flexibility when dealing with different container sizes and shapes. Whether it's containers of various heights, widths, or unique shapes, this machine can adapt well, thus being suitable for a broad variety of application scenarios.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Name |

Description |

|

Filling volume |

30-500ml (customized) |

|

Filling accuracy |

≤±1% |

|

Filling capacity |

500-1000 Can/hr |

|

Can body height |

70-330mm,customization available |

|

Can size |

1 inch |

|

Air source |

0.45-0.7Mpa |

|

Air consumption |

0.8m3/min |

|

Weight |

320kg |

|

Dimension |

900*550*1300mm |

product Applications

1. This equipment has the capability to fill a wide variety of aerosol products, including sprays that are used for numerous purposes, fragrant perfumes that add a touch of elegance, and cleaning agents that help keep our surroundings clean.

2. It is well-suited for diverse industries. In the cosmetics industry, it can handle the packaging of beauty products; in the household sector, it can be used for filling household items; and in the automotive field, it can take care of relevant aerosol products as well.

3. It provides filling that is both efficient and highly accurate, which plays a crucial role in guaranteeing the quality of the filled products and maintaining consistency in every single filling operation.

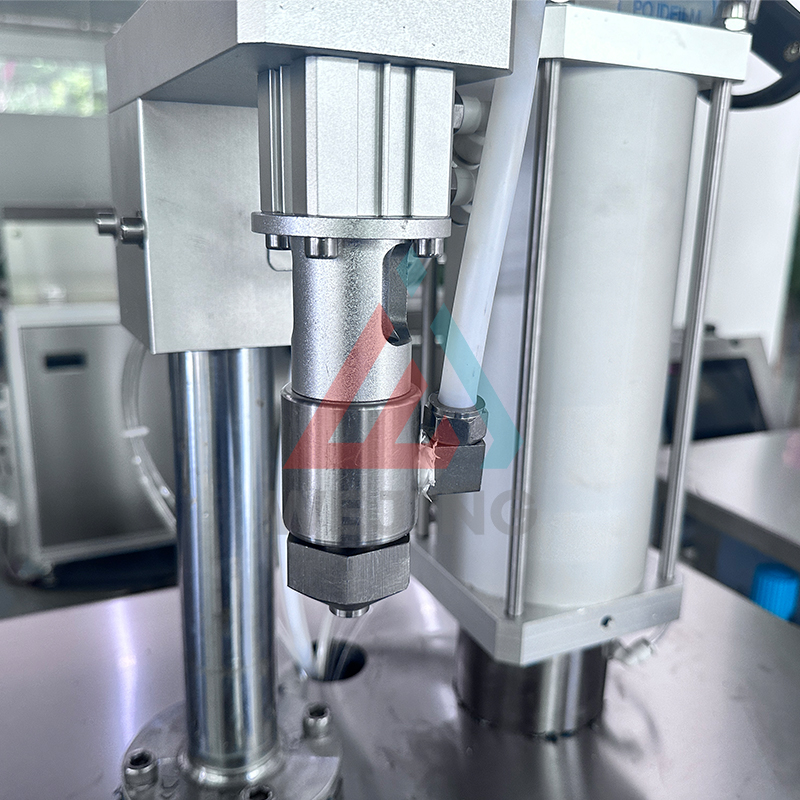

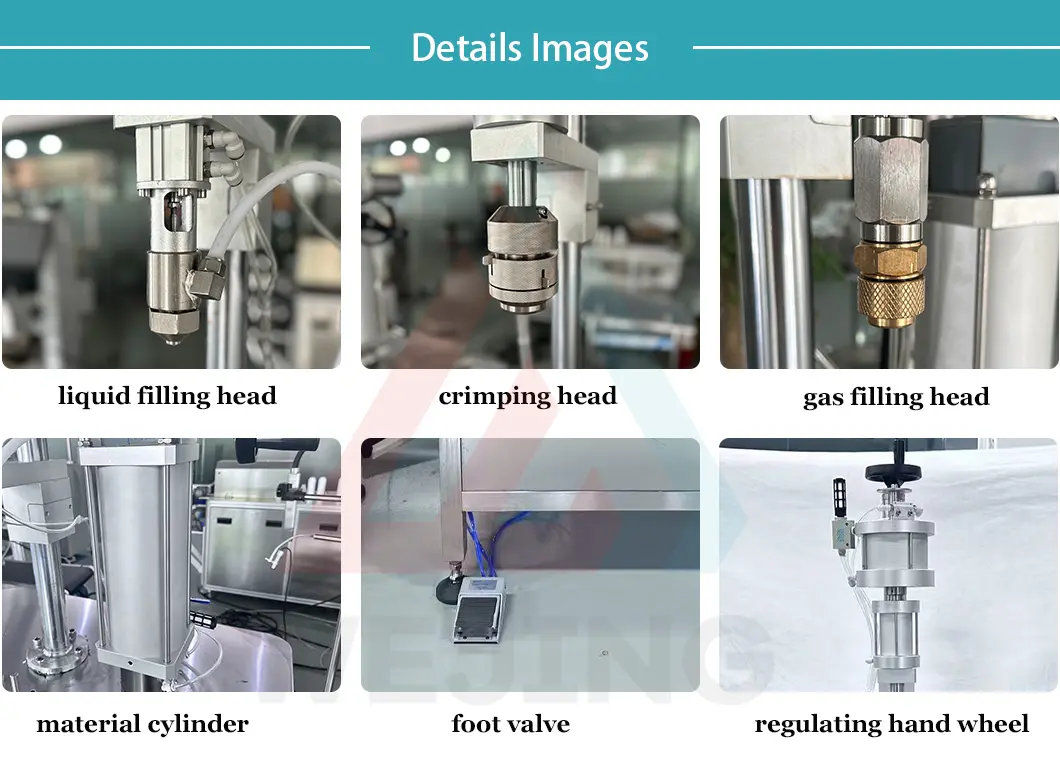

OPERATIONAL PRINCIPLE

1. Automatic Filling: This machine makes use of semi-automatic processes to precisely fill aerosol containers with the appropriate quantities of products. It ensures that each container gets filled with an exact amount, enhancing the accuracy and uniformity of the filling operation.

2. Pressure Regulation: It is designed to uphold the proper pressure during the entire filling process. By carefully controlling the pressure levels, it not only enables the filling to be carried out efficiently but also guarantees the safety of the whole operation, minimizing any potential risks associated with improper pressure conditions.

3. Sealing System: There is a sealing mechanism incorporated into the machine to tightly seal the filled aerosol containers. This effectively prevents any leakage from occurring and safeguards the integrity of the product inside, allowing it to maintain its quality and usability over time.

FAQ

1. What exactly defines a semi-auto aerosol filling machine?

It refers to a machine that is capable of filling aerosol containers with products in a semi-automatic manner, combining both automated functions and some level of manual oversight to complete the filling process.

2. What advantages come with using such a machine?

It brings several benefits, including enhanced efficiency as it speeds up the filling process compared to fully manual methods.

It also ensures high accuracy in the amount of product filled into each container and boosts overall productivity, allowing for more containers to be filled within a given time frame.

3. Is it applicable to different kinds of aerosols?

Certainly, it is compatible with a wide range of aerosol products. Whether it's beauty-related aerosols like perfumes, household-use ones such as air fresheners, or other types, this machine can handle them effectively.

4. How does it guarantee the quality of the filled aerosols?

It achieves this by maintaining precise filling, making sure that each container gets the correct and consistent amount of product. Additionally, it has a leak-proof sealing mechanism that prevents any leakage, thus safeguarding the integrity and quality of the aerosol product over time.

5. Is it user-friendly in terms of operation and maintenance?

Yes, it is designed to be easy to operate. Operators can quickly learn how to use it without extensive training. Moreover, it requires minimal maintenance efforts, which helps to reduce downtime and keep the production process running smoothly.