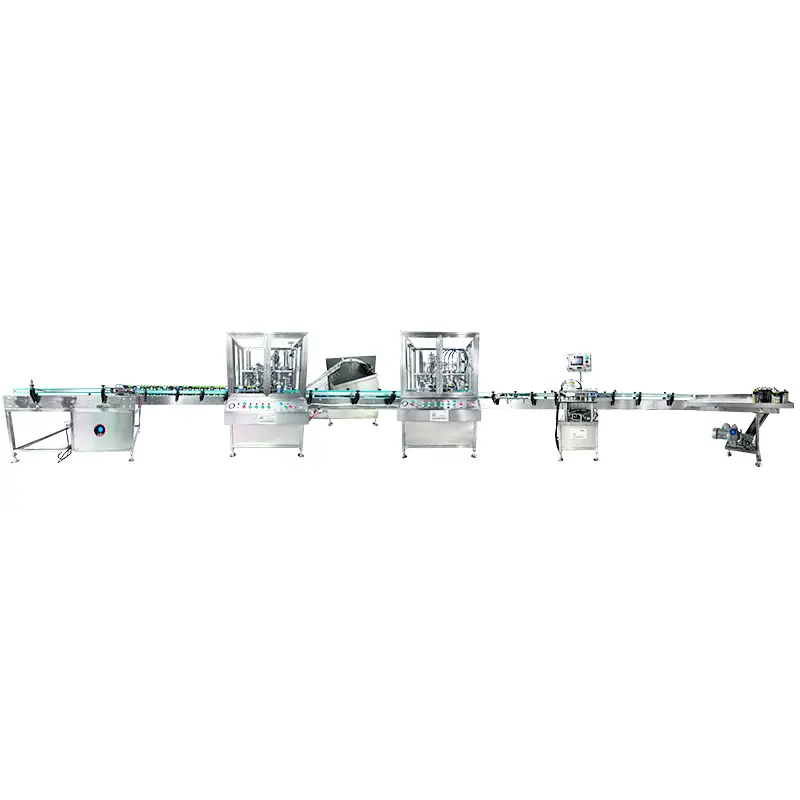

Middle Speed Aerosol Filling Machine

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

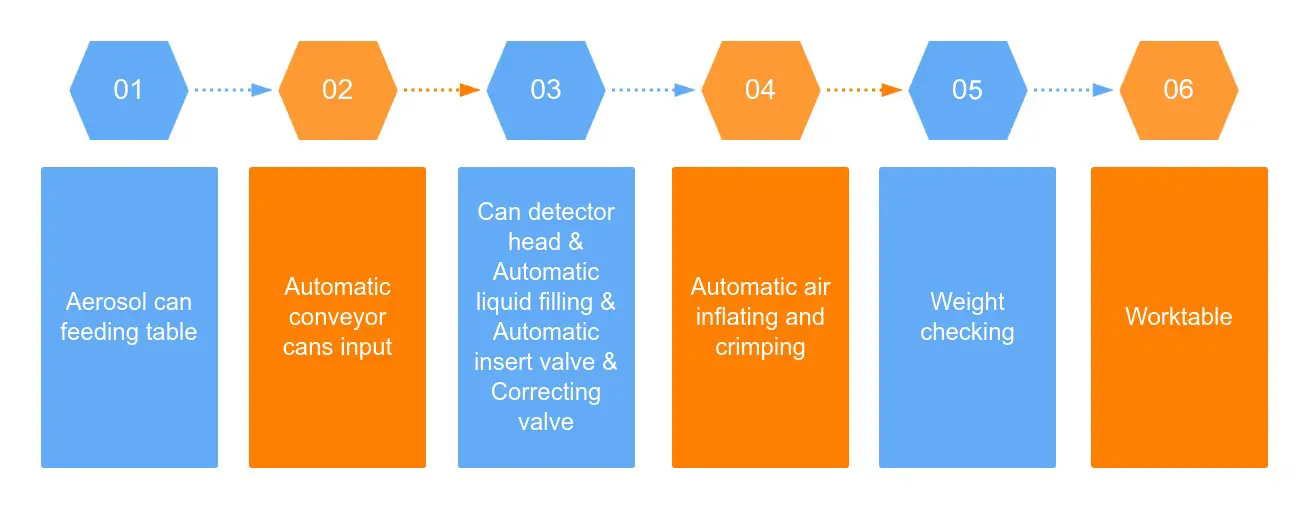

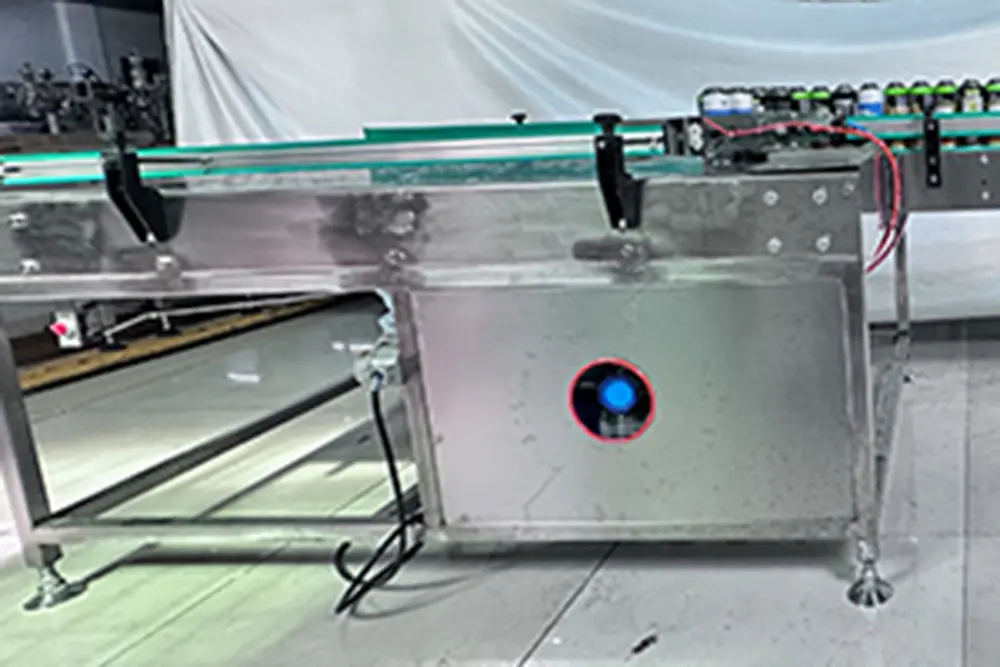

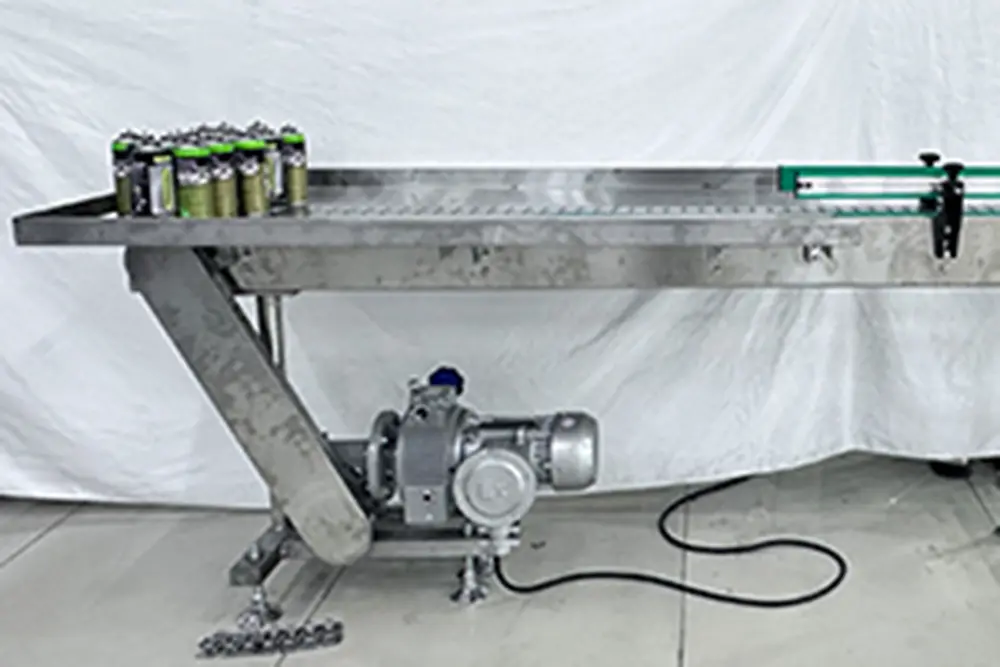

Auto Can Feeding Machine

It is composed of 13 flat-roof conveyor belts, an explosion-proof motor, and associated control components. It has the ability to automatically transfer the cans to the subsequent station, and the speed can be adjusted as needed.

Liquid Filling Machine

This automatic liquid filling machine is equipped with 4 liquid filling heads. Such a configuration empowers users to concurrently fill materials possessing diverse colors or characteristics, thereby fulfilling a wide range of demands. Additionally, the cleaning process for each filling head is remarkably straightforward. These two standout attributes combine to crown this machine as the premier choice among automatic filling apparatuses.

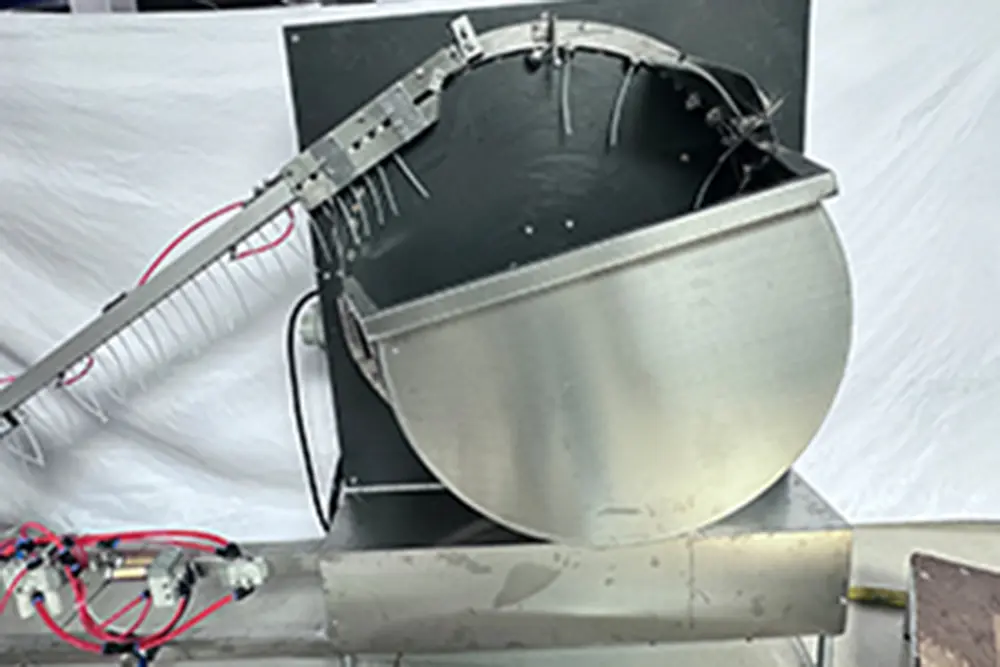

Insert Valve

This Automatic Valve Insert comprises three distinct components. Namely, there is a valve sorting turntable, a valve blowing segment, and a valve placing portion. These elements work in concert to form the cohesive and functional entirety of the Automatic Valve Insert.

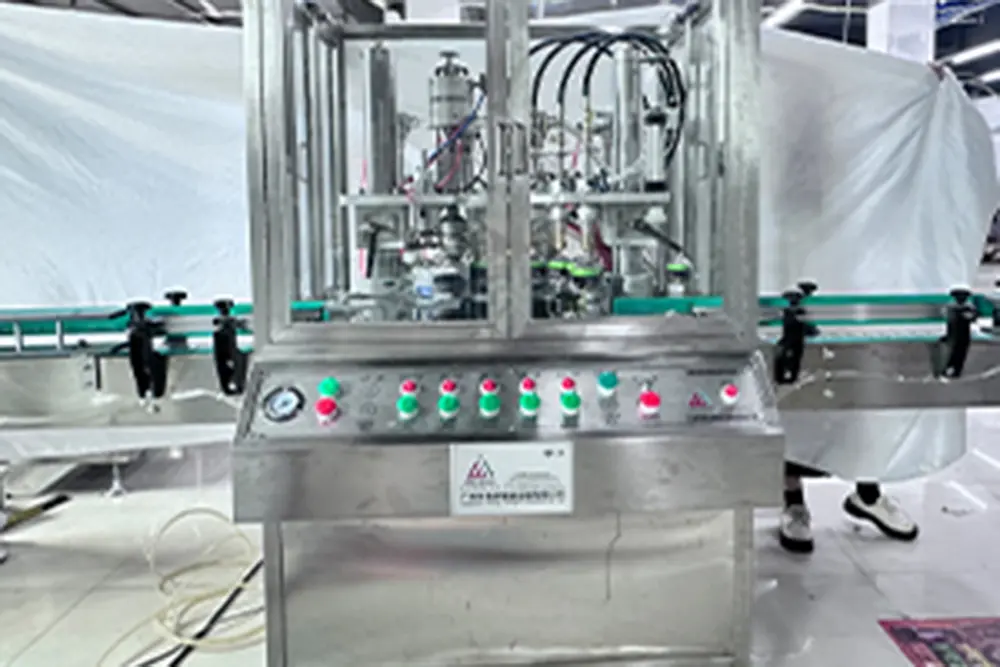

Crimping and Gas Filling Machine

Fully pneumatically-powered elements ensure a secure and risk-free operational process.

The quantity of gas filling nozzles and the amount of gas filling volume can be tailored to specific requirements.

A wide assortment of propellants can be utilized, including compressed air, LPG, DME, CFC, nitrogen, carbon dioxide, and others.

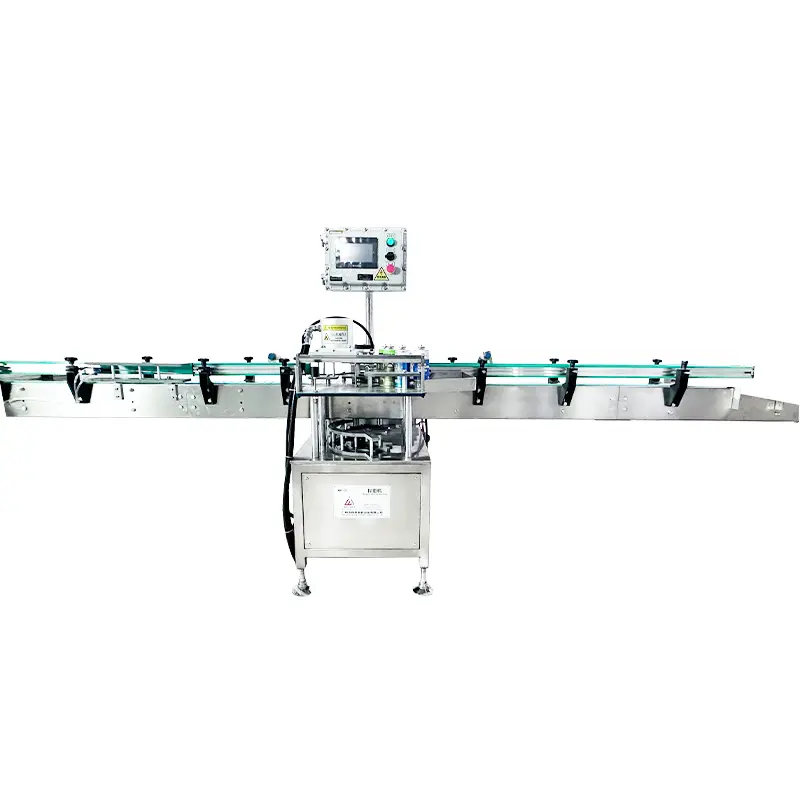

Weight Checking Machine

Immediate weight manifestation allows for intuitive and effortless parameter modification. Additionally, it offers a straightforward weight calibration and adjustment function to accommodate diverse requirements of inspection speed.

Packing Table

This Accumulating Table serves as the concluding apparatus of the QGJ70 Aerosol Filling Machine. It receives the finished cans, enabling operators to collect and package them.

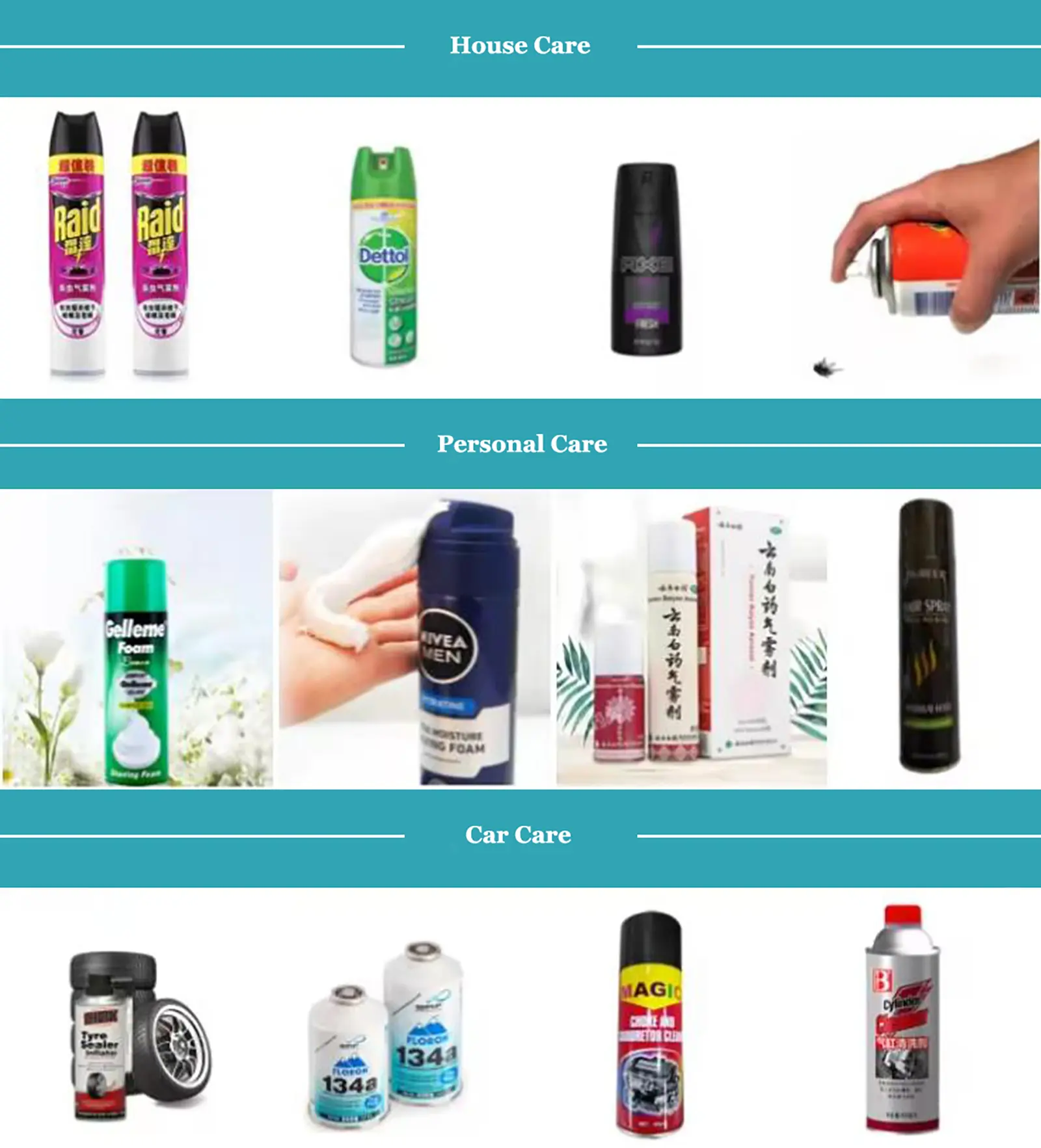

product Applications

Culinary Delights: Aerosol cans might house whipped cream, frosting, chocolate, coffee powders, and even cooking oils.

Domestic Essentials: Pesticides, dust and spot removers, along with air fresheners, are among the typical household items found in aerosol forms.

Medical Realm: In the pharmaceutical field, nasal sprays, saline solutions, multi-dose injectables, and topical aerosols are all prepared with aerosol filling apparatus.

Beauty and Grooming: Sunscreens, shaving gels, foams, deodorants, body sprays, and perfumes are a few of the cosmetic products that rely on aerosol filling machines.

Industrial Applications: Auto upkeep and painting products serve as prime illustrations of the industrial utilization of such devices.

Domestic Essentials: Pesticides, dust and spot removers, along with air fresheners, are among the typical household items found in aerosol forms.

Medical Realm: In the pharmaceutical field, nasal sprays, saline solutions, multi-dose injectables, and topical aerosols are all prepared with aerosol filling apparatus.

Beauty and Grooming: Sunscreens, shaving gels, foams, deodorants, body sprays, and perfumes are a few of the cosmetic products that rely on aerosol filling machines.

Industrial Applications: Auto upkeep and painting products serve as prime illustrations of the industrial utilization of such devices.

selecting product

1. Output Capacity: The machine's productivity must match the volume demands of your production.

2. Product Compatibility: Ensure the machine has the aptitude to manage your particular product mix and propellant type.

3. Degree of Automation: Decide, considering your financial plan and production magnitude, between a semi-automated or a fully automated option.

4.Excellence and Dependability: Opt for a well-known manufacturer to ensure the machine's trustworthiness and access to proper assistance.

2. Product Compatibility: Ensure the machine has the aptitude to manage your particular product mix and propellant type.

3. Degree of Automation: Decide, considering your financial plan and production magnitude, between a semi-automated or a fully automated option.

4.Excellence and Dependability: Opt for a well-known manufacturer to ensure the machine's trustworthiness and access to proper assistance.

Our Service

Our Service Excellence for Peak Efficiency:

We offer a comprehensive suite of services including remote technical aid, on-site maintenance, operator training, and meticulous machine evaluations. Our seasoned OEM Parts Division and innovative Modernization squad are at your disposal. With profound insights into your machinery, we minimize operational disruptions, extend equipment longevity, and amplify your return on investment.

Post-Sale Support:

1. A two-year warranty safeguards your investment.

2. Our proficient engineers are primed to address overseas machinery servicing needs.

3. Our dedicated professional sales representatives stand by to assist you.

4. We can provide customized factory blueprints, spatial arrangements, installation guidance, and training programs.

5. We ensure seamless machine operation with a 100% usability guarantee, underpinned by detailed machine testing videos.

We offer a comprehensive suite of services including remote technical aid, on-site maintenance, operator training, and meticulous machine evaluations. Our seasoned OEM Parts Division and innovative Modernization squad are at your disposal. With profound insights into your machinery, we minimize operational disruptions, extend equipment longevity, and amplify your return on investment.

Post-Sale Support:

1. A two-year warranty safeguards your investment.

2. Our proficient engineers are primed to address overseas machinery servicing needs.

3. Our dedicated professional sales representatives stand by to assist you.

4. We can provide customized factory blueprints, spatial arrangements, installation guidance, and training programs.

5. We ensure seamless machine operation with a 100% usability guarantee, underpinned by detailed machine testing videos.