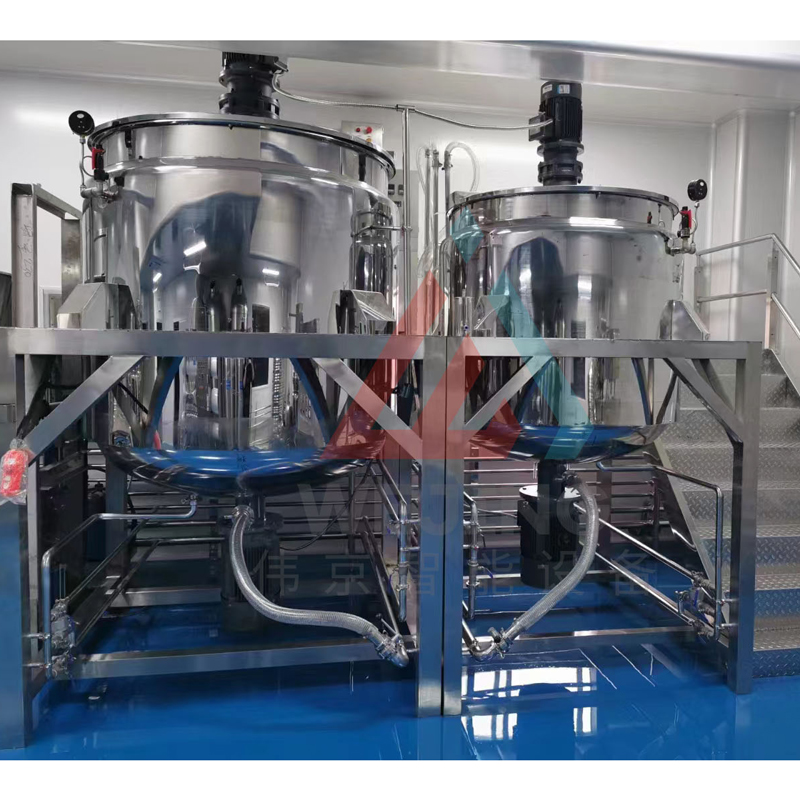

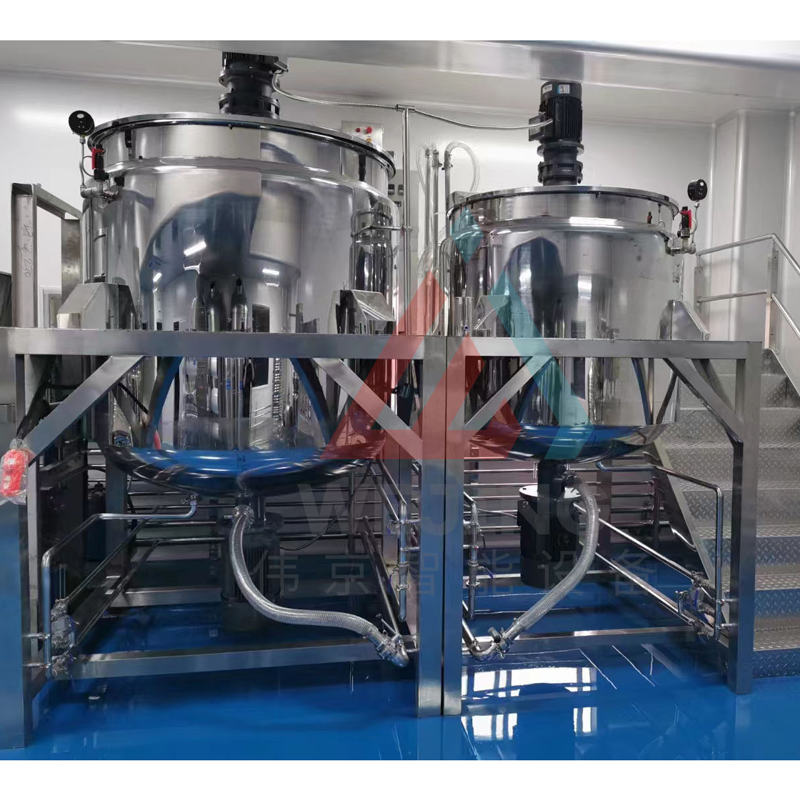

Mixing Tank Homogenizer Optional Heating Function

Mixing Tank With AgitatorPRODUCT PARAMETERS

|

Model |

Capacity (L) |

Mixing |

Homogenization |

||

|

Power (kW) |

Speed (rpm) |

Power (kW) |

Speed (rpm) |

||

|

WJ-M50 |

50 |

0.55 |

0-60 |

1.5 |

0-3000 |

|

WJ-M100 |

100 |

0.75 |

0-60 |

1.5 |

0-3000 |

|

WJ-M200 |

200 |

1.5 |

0-60 |

3 |

0-3000 |

|

WJ-M300 |

300 |

2.2 |

0-60 |

4 |

0-3000 |

|

WJ-M500 |

500 |

2.2 |

0-60 |

5.5 |

0-3000 |

|

WJ-M1000 |

1000 |

4 |

0-60 |

11 |

0-3000 |

|

WJ-M2000 |

2000 |

5.5 |

0-60 |

15 |

0-3000 |

|

WJ-M3000 |

3000 |

7.5 |

0-50 |

18.5 |

0-3000 |

|

WJ-M5000 |

5000 |

11 |

0-50 |

22 |

0-3000 |

The working principle of a homogenizer is to disperse, crush, and mix materials through the shear force, impact force, and turbulence generated by the high-speed rotating agitator and homogenizer. Different types of homogenizers have different mixing and homogenization methods, which can be selected according to specific application needs.

Product Advantages

1. Efficiency: Able to complete material mixing and homogenization in a short period of time, greatly improving production efficiency.

2. Good uniformity: The material can be evenly mixed and dispersed to ensure consistency in product quality.

3. Wide applicability: It can handle materials of various properties, including liquids, semi-solid and high viscosity materials.

4. Easy to operate: Usually equipped with an automated control system, it is easy to operate and master.

5. Easy to clean: The structural design of the equipment is reasonable, making it easy to clean and maintain, reducing the risk of cross contamination.

2. Good uniformity: The material can be evenly mixed and dispersed to ensure consistency in product quality.

3. Wide applicability: It can handle materials of various properties, including liquids, semi-solid and high viscosity materials.

4. Easy to operate: Usually equipped with an automated control system, it is easy to operate and master.

5. Easy to clean: The structural design of the equipment is reasonable, making it easy to clean and maintain, reducing the risk of cross contamination.

Product Applications

1. In the food industry, it's employed to produce sauces, juices and other items, enhancing the taste to a more refined and uniform level.

2. For the chemical industry, it can be utilized to blend various chemical reagents, coatings, inks and so on, thus guaranteeing the stability and quality of products.

3. In the pharmaceutical industry, it's used for preparing drug suspensions and emulsions and the like, which helps to boost the bioavailability of drugs.

4. In the cosmetics industry, it's applied to make lotions, face creams and other cosmetic products, making them more refined and easier to be absorbed.

2. For the chemical industry, it can be utilized to blend various chemical reagents, coatings, inks and so on, thus guaranteeing the stability and quality of products.

3. In the pharmaceutical industry, it's used for preparing drug suspensions and emulsions and the like, which helps to boost the bioavailability of drugs.

4. In the cosmetics industry, it's applied to make lotions, face creams and other cosmetic products, making them more refined and easier to be absorbed.