Cartridge Gas Aerosol Filling Machine

The fully automatic box type aerosol filling machine is efficient and accurate. It consists of filling system, transmission system, control system, etc. There is a sealing device to ensure good sealing. Equipped with four filling heads to improve filling efficiency, the speed can reach 60-70 cans/minute. The filling volume can be adjusted between 10-300 milliliters to meet different needs. High degree of automation, easy operation, widely used in aerosol product filling, providing strong guarantee for efficient production of enterprises.

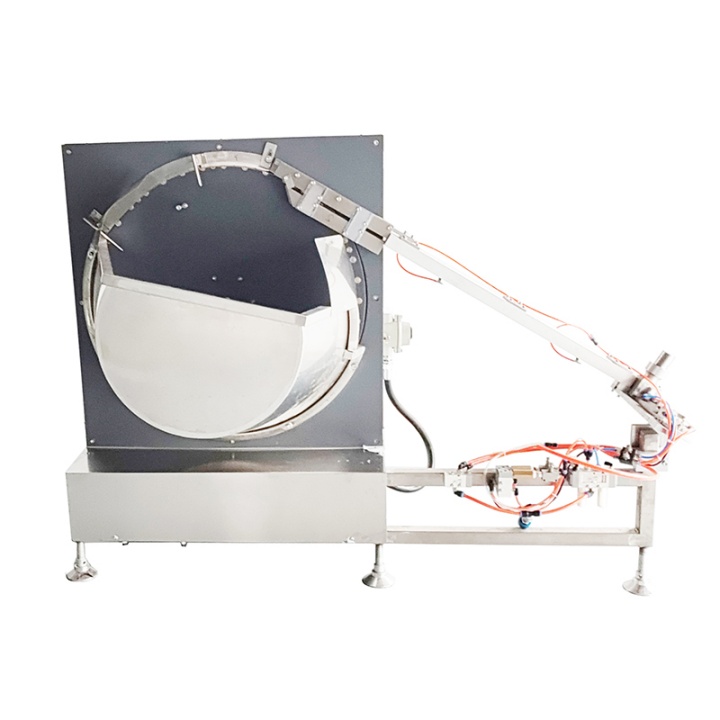

Card Furnace Gas Tank Filling Machine

The Cartridge gas filling machine is bespoke apparatuses crafted to proficiently, precisely, and securely fill gas tanks used in card furnaces and aerosol spray items. Incorporating state-of-the-art technologies, it warranties exact gas quantity control, accommodation for diverse gas varieties, and strict observance of safety regulations, thus emerging as an essential implement within the relevant industrial sectors.

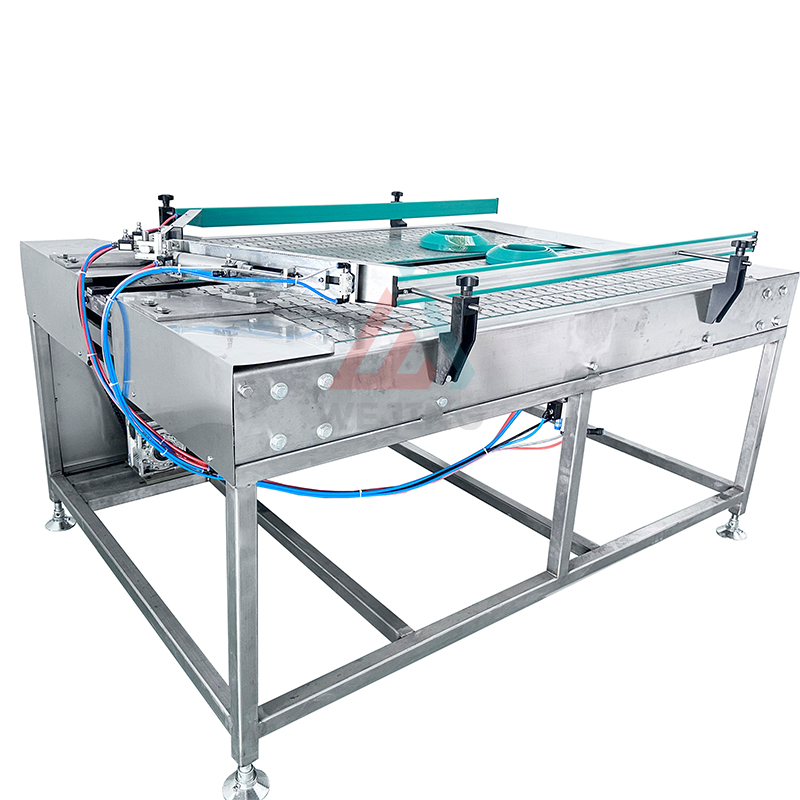

Automatic Aerosol Valve Inserted Machine

The Automatic Valve inserted machine is structured with a valve selection system, a valve insertion setup, and a valve pressing mechanism. It serves as a high-speed and accurate valve insertion device. It can work with diverse valve types and sizes, guaranteeing stable and dependable valve insertion. This equipment boosts production efficiency and tightens quality control, thus emerging as a top-notch option for aerosol filling lines.

Aerosol Insecticide Filling Sealing M...

The fully automatic aerosol filling machine is an efficient automated filling equipment that uses air pressure to allow liquid to flow from the filling head into the can. It is equipped with technical assistance such as liquid level detection, pressure balance, and drip prevention to ensure accurate, stable, and leak free filling.

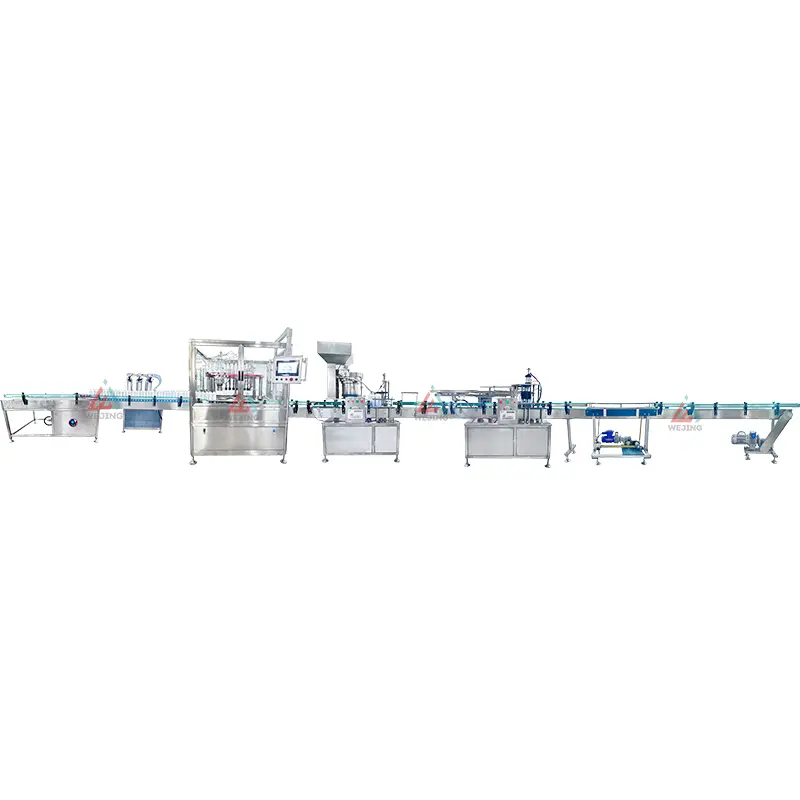

QGJ150 Automatic Aerosol Filling Machine

QGJ150 fully automatic aerosol filling line is an efficient aerosol filling equipment. Composed of 8-head liquid filling machine for bottle sorting, rotary table valve insertion and edge pressing machine, rotary table 8-head gas filling machine, compressed air plunger pump, upper valve machine, weighing machine, nozzle press machine, and capping machine.

7200 BPH Aerosol Filling Machine

The Fully Automated Aerosol Filling System revolutionizes the way aerosol products are made. It combines various automated processes such as can supply, valve connection, filling of contents, propellant addition, and sealing. With precise control mechanisms, this system maximizes the use of resources. It significantly increases production efficiency and ensures that every product has the same high - quality standard. Thanks to its user - friendly design, it's easy to operate. Moreover, it complies with strict hygiene requirements. For companies in the aerosol production business, it's a reliable choice.

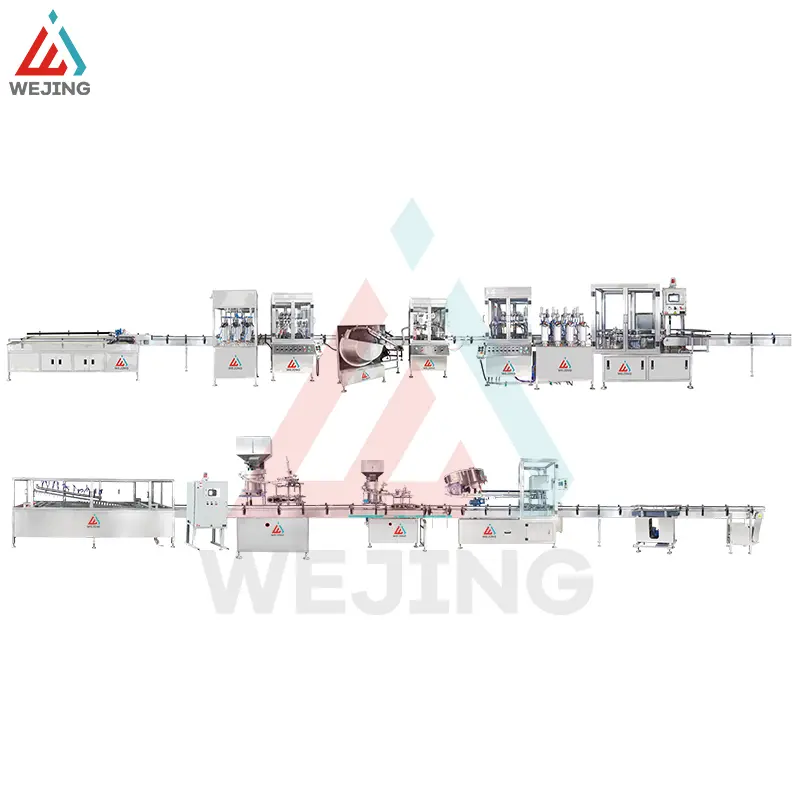

QGJ120 Aerosol Filling Machine Line

The QGJ120 automatic aerosol filling line is an efficient filling equipment. It is equipped with multiple inflation heads and can be flexibly configured with 80 or 10 inflation heads according to production requirements. The filling line adopts a wheel design, which can fill two cans at once and produce two cans at a time, greatly improving production efficiency. The filling speed can reach 90-120 cans per minute, which can quickly meet the needs of large-scale production.The filling capacity is 30-1200 milliliters, suitable for filling various aerosol products. The device has a high degree of overall automation, easy operation, effectively reduces labor costs, improves product quality and stability, and provides efficient and reliable production solutions for aerosol manufacturers.

QGJ150 LPG Spray Filling Machine

The automatic aerosol filling line consists of a filling machine turntable with 8/10 heads, a valve clamping machine turntable, a gas filling machine turntable with 8/10 heads, a compressed air plunger pump, a conveyor, a conveyor belt, etc. D. Other matters The filling line speed can reach 130-150 cans/minute, and the filling volume is 30-1200 milliliters.

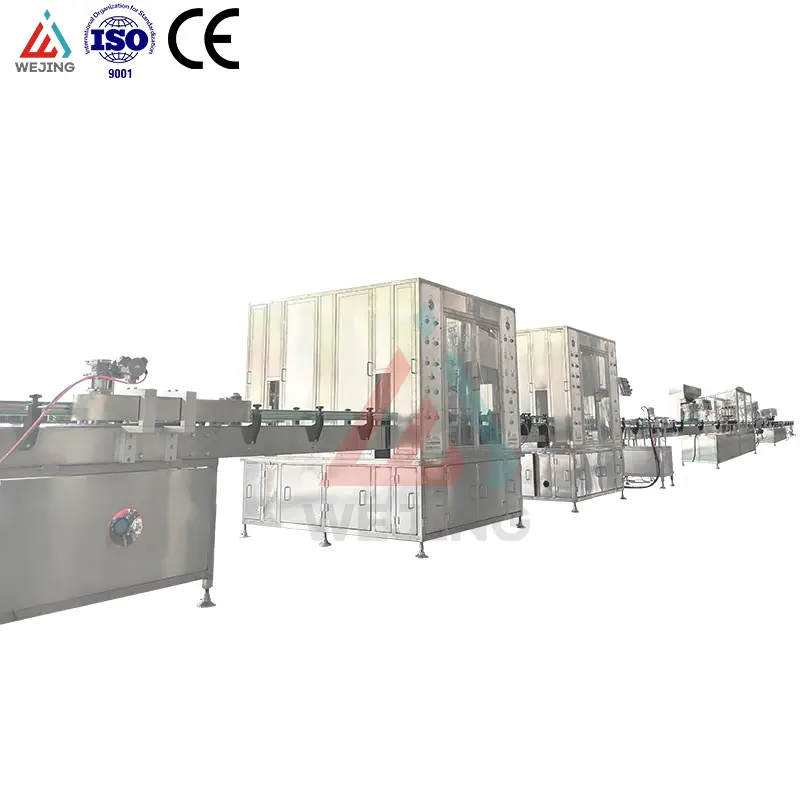

9000 BPH Aerosol Filling Machine

The Complete Aerosol Filling Automation Solution makes the production process simpler. It combines automatic can feeding, valve setting, putting in contents, adding propellant, and sealing. With careful control, it makes better use of resources, speeds up production, and keeps the product quality the same. There is an operator interface that's easy to use. The system also meets very strict hygiene rules. It's a good and reliable choice for businesses that make aerosol products.

Auto Plastic Cap Inserting Machine

Wejing is proud to introduce the High - Speed Auto Plastic Cap Inserted And Fixed Machine. With our twelve - head rotation system, the production speed is remarkably increased while the labor requirements are decreased. The innovative design guarantees stable quality, reduces losses to the minimum, and improves efficiency. For your high - speed plastic cap insertion requirements, Wejing is your top choice. Get in touch with us right now!

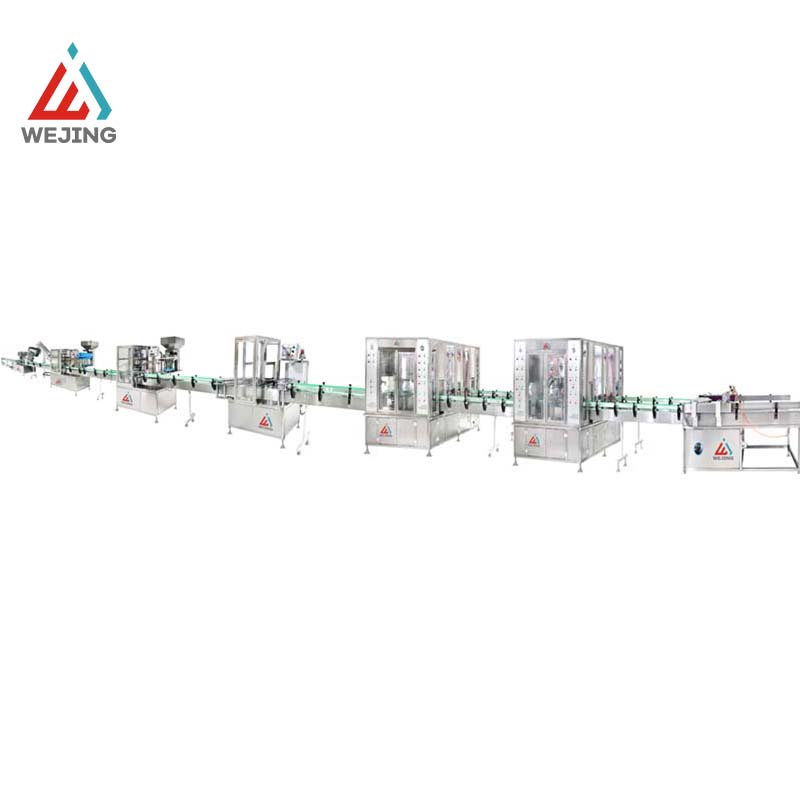

10-1200ml Aerosol Production Line

Wejing specializes in manufacturing the 10 - 1200ml Automatic Aerosol Filling Machine, which are hot - selling aerosol spray fillers. Our high - speed production line has a double rotary table design, capable of twelve - head liquid filling and ten - head gas filling. It combines valve inserting, crimping, and conveyor systems, integrating multiple processes into one highly efficient line. Just let us know your requirements, and we'll offer you the perfect aerosol filling solution to meet your needs.

Aerosol Cans Weight Checker Machine

The Fully Automatic Aerosol Weight Checking Machine represents a top - notch solution for accurate and efficient weighing during aerosol production. It's an advanced piece of equipment that utilizes the latest technology and comes with a high - precision weighing mechanism. This enables it to provide precise measurements each time it's used. Renowned as the premier weight - measuring device in the industry, it ensures stable and trustworthy results, fulfilling the strict quality demands of aerosol manufacturing. Moreover, thanks to its built - in checkweigher, this machine makes sure that every aerosol product complies with the set weight criteria, reducing product discrepancies to a minimum and enhancing customer contentment to the fullest.