Deodorant Spray Aerosol Filling Machine

Semi-automatic aerosol liquid filling machine is capable of single liquid filling, with flexible operation and suitable for small-scale production. Accurate control of filling volume through piston structure, with high precision. Can be filled with various liquids, with relatively low cost. Widely used in cosmetics, pharmaceuticals and other fields, it is an ideal choice for small businesses and laboratories, which can effectively improve production efficiency and product quality.

Manual Aerosol Liquid Forced Filling ...

Semi-automatic forced aerosol infusion machine works in a combination of advanced mechanical and pneumatic technologies. It forcefully injects liquid materials into the aerosol can under a certain pressure through a specific pump body and pipeline system. Usually, after the operator places the empty aerosol can in the designated location, the equipment will automatically perform the liquid filling operation to ensure that each aerosol can can accurately inject the preset amount of liquid.

BOV Aerosol Liquid Forced Filling Mac...

The forced aerosol liquid filling machine is a semi-automatic packaging equipment. It is mainly used to fill materials such as liquids and gases into aerosol cans. This equipment adopts advanced technology, which can accurately control the filling volume and pressure, ensuring stable product quality. Easy to operate, capable of achieving automated production and improving production efficiency. The forced aerosol filling machine has good sealing performance, which can effectively prevent material leakage and external pollution. Widely used in industries such as cosmetics, pharmaceuticals, and food, providing reliable packaging solutions for enterprises, meeting the filling needs of different products, and helping enterprises enhance market competitiveness. Can be filled with both single and binary aerosol products

Semi Auto Independent Filling Machine

The semi-automatic aerosol filling machine mainly consists of three parts: liquid filling, sealing, and gas filling. In the filling section, a precise dosing system is used to accurately spray the required liquid into the aerosol bottle, ensuring that the capacity of each cylinder matches and laying the foundation for product quality. Then enter the sealing stage, where advanced sealing technology ensures the sealing of the aerosol bottle, effectively preventing liquid leakage and external impurities from penetrating. During the inflation phase, precise control devices are used to inject the required amount of gas into the cylinder, ensuring complete mixing of liquid and gas for optimal results. The semi-automatic operation mode not only ensures a certain level of production efficiency, but also allows operators to control and adjust each link at any time. The detachable design makes equipment maintenance and troubleshooting more convenient, providing a reliable guarantee for the production of aerosol products.

Manual 3 in 1 aerosol filling machine

The semi-automatic aerosol filling machine 3-in-1 has three functions: liquid filling, sealing, and inflation. During the filling stage, this machine can accurately control the filling amount to ensure that the liquid volume of each aerosol bottle is consistent, providing reliable assurance for product quality. The subsequent sealing process adopts advanced sealing technology to strictly ensure the sealing of the aerosol bottle, effectively preventing liquid leakage and external impurities from entering. During the inflation process, the accurately measured gas is sprayed into the tank and completely mixed with the liquid to achieve the best usage effect. The semi-automatic design not only automates the process to a certain extent, improves efficiency, but also makes it easier for operators to control and adjust anytime and anywhere, providing an efficient and reliable solution for aerosol production.

4 in 1 Manual Aerosol Equipment

The semi-automatic 4-in-1 aerosol filling machine is an efficient and practical equipment. It combines four functions: liquid filling, valve correction, compression sealing, and inflation. During the filling process, the filling volume can be precisely controlled, suitable for different liquids of different properties. The valve calibration function ensures precise valve position and improves inflation airtightness. Compression sealing ensures reliable sealing and effectively prevents product leakage and external contamination. The inflation function can be used for inflating specific gases according to requirements. The control of the filling machine is relatively simple, and the semi-automatic mode reduces work complexity while ensuring efficiency. Widely used in many industries, providing cost-effective production solutions for enterprises, helping them improve product quality and production efficiency, and reduce production costs.

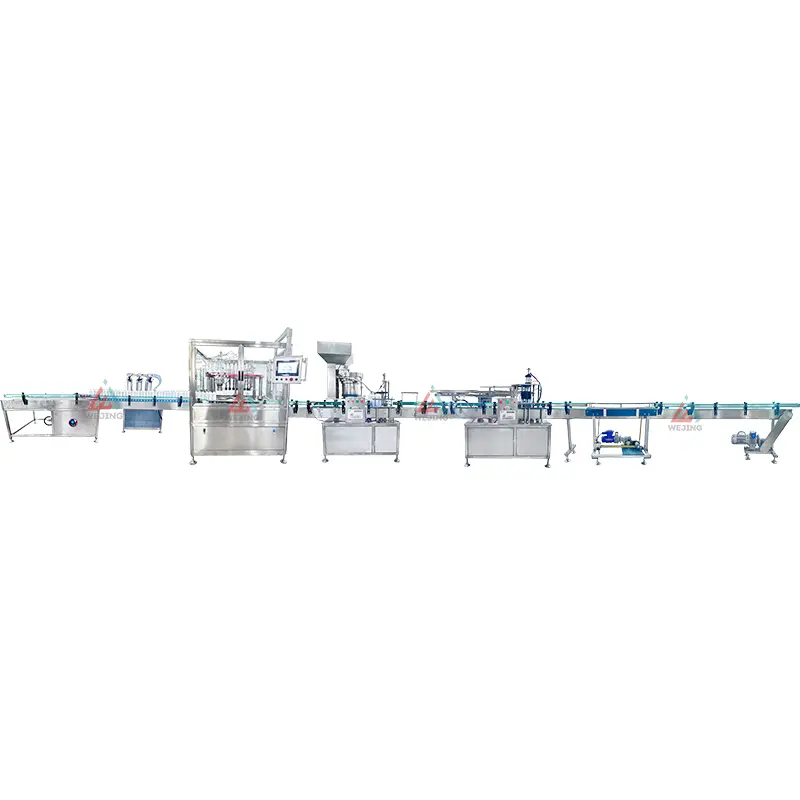

Full Auto BOV Aerosol Filling Line

Fully automatic bag on valve filling line is an efficient and precise filling equipment suitable for the production of various binary aerosol products. It integrates multiple functions such as inflation, liquid filling, pressure measurement, and cleaning, and can achieve fully automated production, greatly improving production efficiency and product quality.

Automatic Bag On Valve Filling Machine

BOV aerosol filling machine is efficient and practical. Contains multiple inflation, infusion, pressure measurement, and cleaning heads, with a speed of 45-60 cans/minute and a filling volume of 30-1200ml. Inflate and seal before filling, integrating multiple functions, suitable for industries such as cosmetics and pharmaceuticals, ensuring product quality and production efficiency.

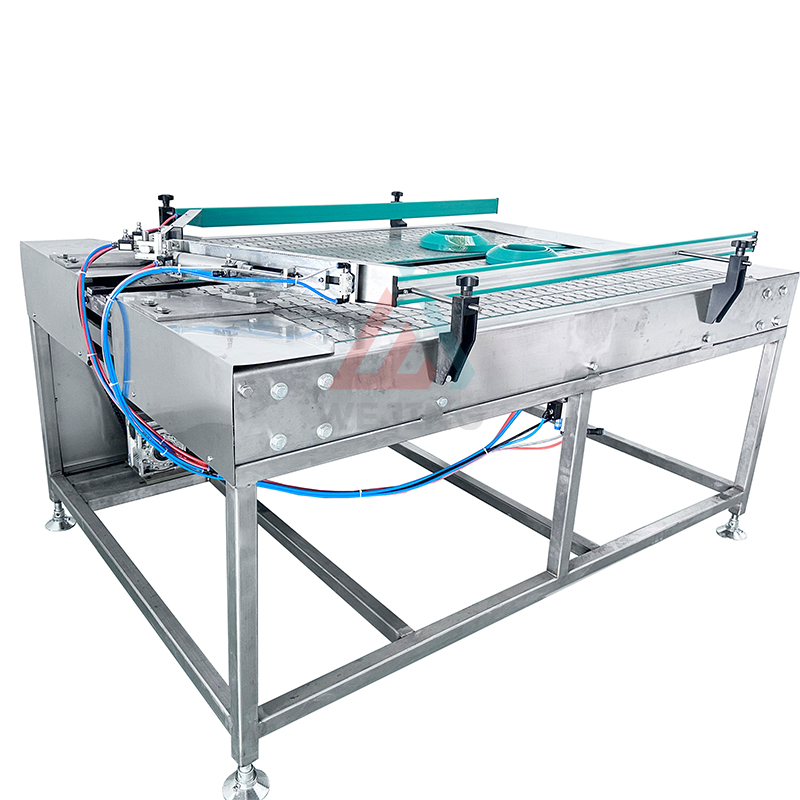

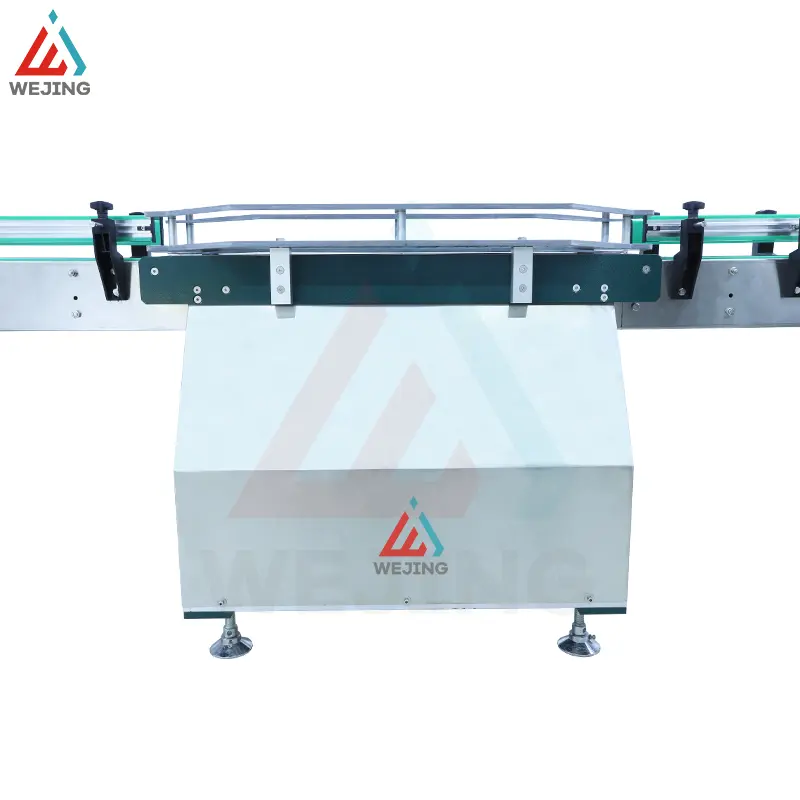

Bov Aerosol Inkjet Conveyor Belt

A coding tape designed specifically for aerosol filling machines: a breakthrough solution aimed at improving the efficiency and accuracy of aerosol production. Our multifunctional and portable conveyor system is currently available for purchase and can be seamlessly integrated into various production settings.

This compact and space saving small conveyor ensures smooth transportation of aerosol containers and facilitates precise inkjet marking, which is crucial for label and batch identification. By relying on our aerosol filling machine inkjet conveyor belt, optimize your production and improve label accuracy.

Aerosol Conjoined Lid Capping Machine

The aerosol can press joint cover machine is a device specifically designed to press the joint cover onto the aerosol can.

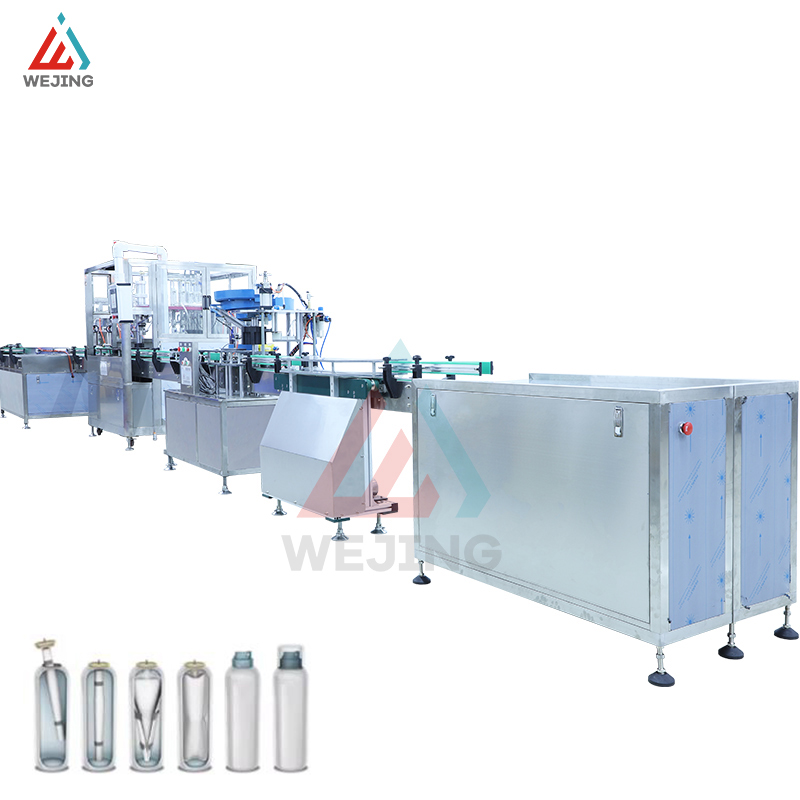

Automatic Bov Bag On Valve Filling Ma...

This production line consists of a bottle feeder, a filling machine, and an automatic nozzle extrusion equipment. Can be connected to automatic cover press, automatic labeling machine, and automatic packaging system to form an assembly line.

This machine is specially designed for filling various aerosol products, including spray, foam and liquid. It is equipped with a convenient touchscreen interface, allowing operators to easily manage and control the loading process. This machine is equipped with multiple nozzles, allowing you to fill multiple gas cylinders simultaneously.

Self-operated Bov Aerosol Filling Mac...

BoV split type aerosol filling machine is an advanced packaging equipment mainly used for the production of aerosol products. It consists of two independent machines, one responsible for sealing and inflating, and the other responsible for filling liquids.