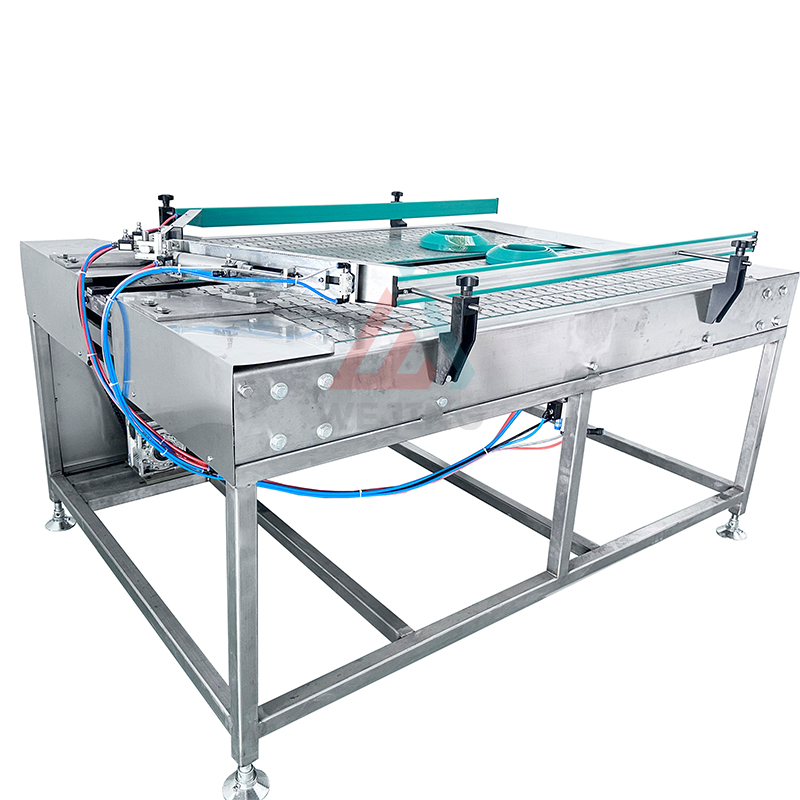

Toothpaste Vaccum Mixing Machine

Vacuum paste machines are widely used in industries such as toothpaste production, cosmetics, food, and chemical engineering to produce sticky paste. The complete set of equipment consists of a paper machine, a pre mixing pot, a glue tank, a powder tank, a glue pump, and a control platform. By adopting advanced mixing technology, multiple raw materials can be quickly and uniformly mixed. Easy to manage and highly automated can improve production efficiency. Designed to be sturdy and durable, easy to clean and maintain, ensuring product hygiene and quality.

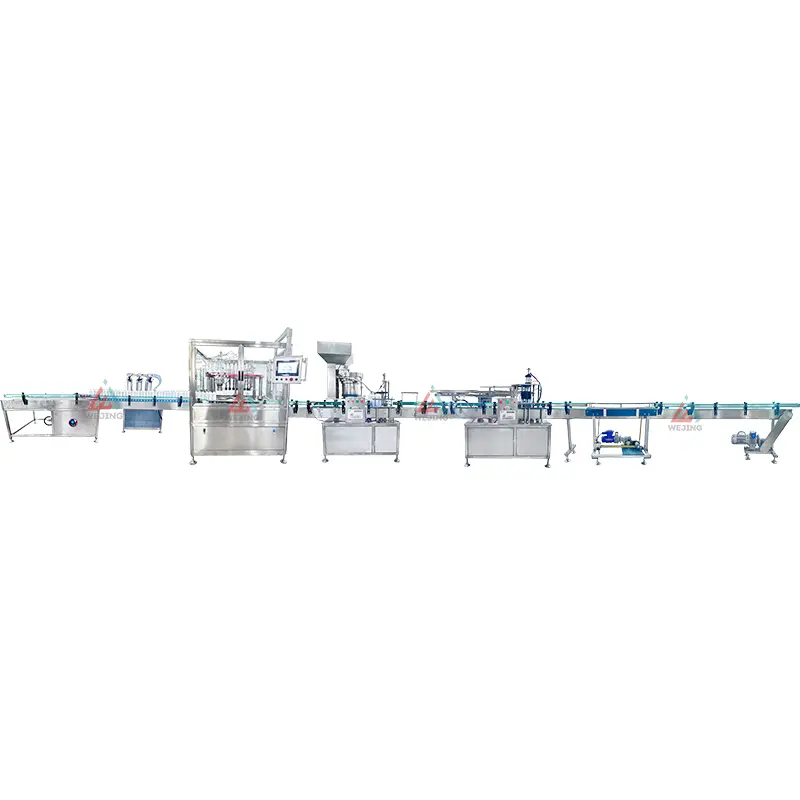

6 Heads Facial Mask Filing Machine

The 6 - Heads Facial Mask Filling Machine is an amazing piece of equipment in the beauty facial mask production industry. Its six heads, which are precisely engineered, cooperate with each other to fill the masks with liquids in a smooth manner. This machine is designed with high - quality technology, allowing for seamless operation and ensuring high - quality production.

8 Heads Beauty Facial Mask Packaging ...

The 8 - Heads Facial Mask Filling Packing Machine is tailor - made for the cosmetic field. This machine is equipped with 8 filling heads, which enables it to operate with high efficiency. It can precisely fill and pack facial masks. Moreover, it features stable performance and is easy to operate, thus fulfilling production requirements.

10 Heads Facial Mask Filling Sealing ...

The 10 - Heads Cosmetic Beauty Facial Mask Filling Packing Machine is incredibly efficient. It can accurately fill and pack facial masks. Equipped with 10 filling heads, this machine significantly increases productivity. It's perfect for the cosmetic industry as it ensures high - quality packaging of masks throughout the production process.

Primary Water Treatment Equipment

The primary reverse osmosis water treatment equipment is an efficient water treatment device designed specifically for industrial applications.

It adopts advanced reverse osmosis technology and uses a semi permeable pressure membrane. The semi permeable membrane only allows water molecules to pass through and does not allow impurities such as dissolved salts, colloids, microorganisms, and organic matter in water to pass through. Under pressure, clear water enters the production side through a semi permeable membrane, effectively removing various impurities, salts, organisms, microorganisms, etc., and outputting high-purity industrial water.

Secondary Water Treatment Equipment

This machine plays an important role in the water treatment process.

It usually consists of multiple processing units used for further processing of pre-treated water. The general purification process includes filtration, adsorption, and ion exchange. These processes remove impurities from water, such as particulate matter, organic matter, heavy metal ions, etc. Its purity is getting higher and higher.

Water Treatment Equipment with EDI

EDI reverse osmosis two-step water treatment is an efficient water treatment technology. Firstly, most impurities and ions are removed from water through two-stage reverse osmosis. Then, EDI (Electrodeionization) technology provides deep purification of water without the need for chemical regeneration, allowing for stable acquisition of high-purity water. It effectively removes organic matter, microorganisms, and various salts, ensuring that water quality meets the strict requirements of industry and pharmaceuticals, providing a reliable water source for production and experimentation, and is an advanced solution for modern water treatment.

Single Head High-speed Filling Machine

Fully automatic single head filling machine with efficient and precise liquid and paste filling capabilities. This machine is easy to operate and can quickly complete filling tasks, improving productivity. Its single head design meets the needs of small-scale production, ensuring stability and reliability. The unique design provides a filling process without droplets and residues. Compact size, not taking up too much space. For small businesses in different industries, this filling machine is an ideal choice, providing reliable protection for their production and helping to effectively fill products.

Vertical Liquid Paste Filling Machine...

The semi-automatic paste liquid filling machine is a practical filling equipment. It can pour out various beverages, therapeutic water, and other liquids. D. And pour in noodles such as cosmetics and soy sauce. The device adopts a vertical structure, which is compact and occupies a small space. The operation is relatively simple and does not require complex techniques to start working. Although the equipment is semi-automatic, it has high filling efficiency and can meet the needs of small and medium-sized enterprises. Stable and reliable operation makes it a reliable choice for enterprises.

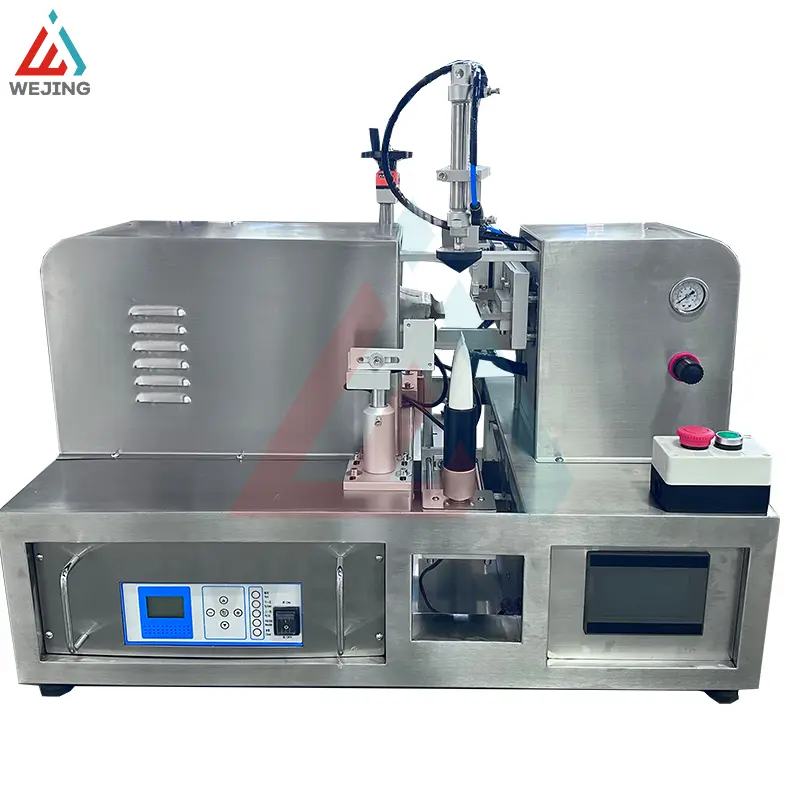

Automatic Tube Filling Sealing Machine

The fully automatic filling and sealing machine is an efficient packaging equipment. It combines filling and sealing functions on one machine, which can automatically complete various flexible tube packaging operations. This device adopts advanced technology to ensure filling accuracy, and the tail seal is durable and beautiful. Widely used in industries such as cosmetics, pharmaceuticals, and food, it has improved production efficiency, reduced labor costs, and brought huge economic benefits to enterprises.

Semi Automatic Ultrasonic Hose Sealin...

The semi-automatic hose sealing machine is a practical packaging equipment. It is mainly used to seal various hoses. The operation of this device is relatively simple, and through the combination of machinery and manual labor, it can effectively complete the sealing work. Its sealing effect is durable and beautiful, ensuring the sealing performance of the product. Suitable for hose packaging in industries such as cosmetics, pharmaceuticals, and food. The semi-automatic pipe sealing machine has a small footprint, low cost, and can meet the production needs of small and medium-sized enterprises.

Semi Automatic Capping Machine

1. This product is appropriate for interlocking sprinkler heads, pump heads, round bottle caps, and duck cap machinery within various daily - chemical, pharmaceutical, and chemical industries. It utilizes both electric and pneumatic control, achieving high stability.

2. It can lock bottle caps with diverse shapes and sizes, and the locking force is adjustable.

3. This machine is simple to operate and use, serving as an excellent substitute for manual screw - capping.