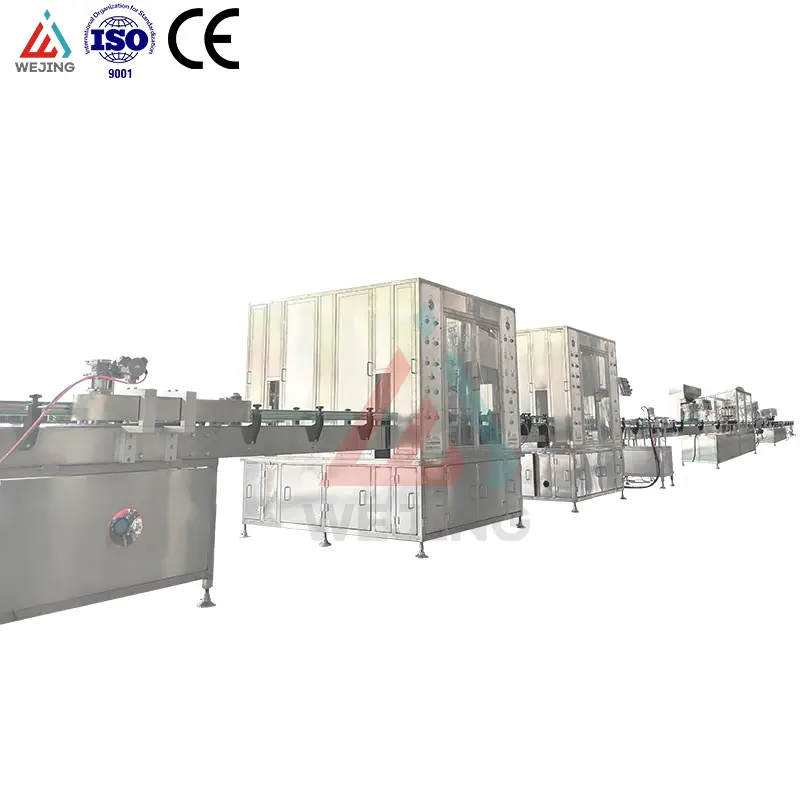

QGJ150 LPG Spray Filling Machine

The production line has the characteristics of high precision and efficiency, and can be filled with 1-inch iron sheets and aluminum cans for international applications. It is also suitable for filling medium viscosity substances such as oil, water, latex solvents, and for filling various propellants such as dimethyl ether, liquefied petroleum gas, R134a, N2, and CO2. It is also suitable for liquid filling in industries such as chemical, cosmetics, food, and medical. It can meet the filling requirements of different specifications and provide efficient and accurate aerosol product filling solutions for enterprises.

High Speed Aerosol Filling MachinePRODUCT PARAMETERS

|

Voltage |

380V/50HZ( can be customized ) |

|

Dimension(L*W*H) |

22000*4000*2000mm |

|

Production speed |

130-150 cans/min |

|

Propellant Type |

The type of propellant used in the aerosol product (e.g., LPG, DME, N₂, CO₂, R134a, etc) |

|

Noise control |

≤80 dB |

|

Can Type |

Tinplate can or aluminum can |

|

Driven Type |

Pneumatic control |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

|

Filling accuracy |

≤±1% |

Can feeding machine

1. Keep the cans fed correctly and orderly on the conveyor belt.

2. High efficiency and low labor intensity.

Filling machine

1.Eight Liquid filling head

2.Plug in valve

3.Two Compression Head

Eight Gas filling head

Weight checking machine

1. Keep the cans fed correctly and orderly on the conveyor belt.

2. High efficiency and low labor intensity.

Actuator fixed machine

Spray driving device for installing aerosol products.

1. Save labor and improve production speed.

2. Improve product quality stability and reduce losses

Plastic capping machine

Outer packaging for plastic caps of aerosol products

Product Characteristics

1. Excellent and efficient production capacity.

2. Accurate filling to ensure quality.

3. High degree of automation.

4. Safety, reliability, and compatibility. Made of high-quality materials, it has good corrosion resistance and wear resistance.

2. Accurate filling to ensure quality.

3. High degree of automation.

4. Safety, reliability, and compatibility. Made of high-quality materials, it has good corrosion resistance and wear resistance.

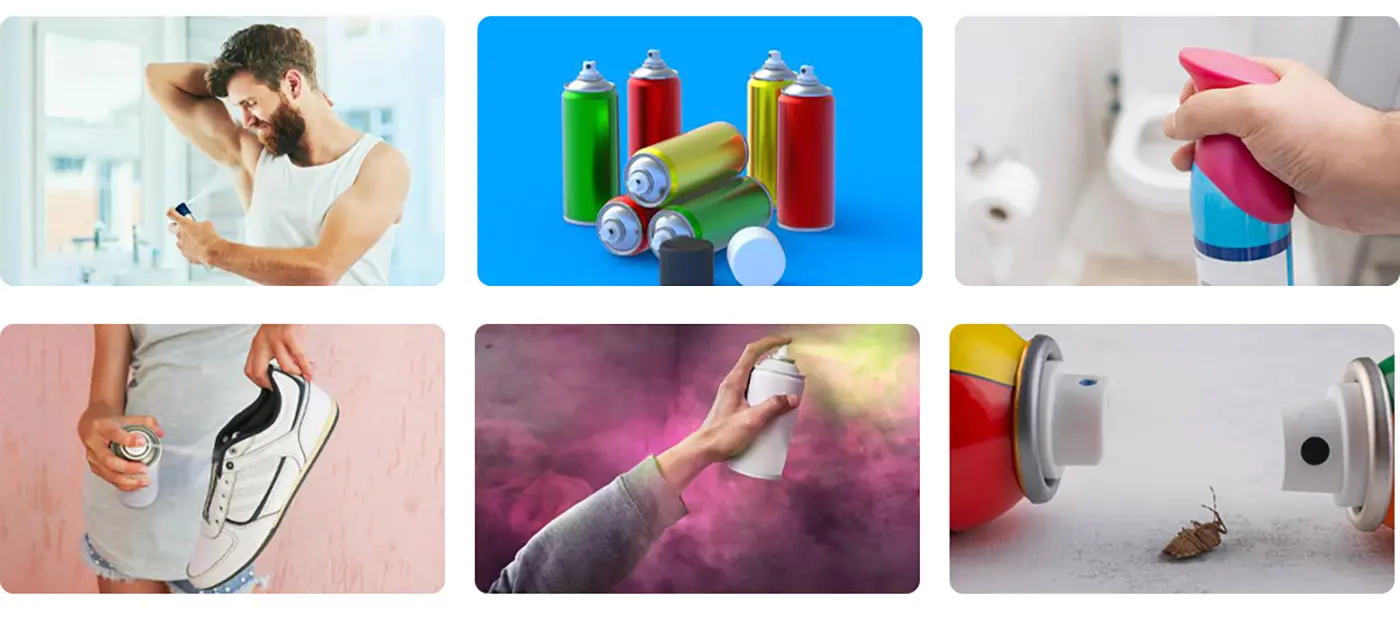

Product Applications

1. Cosmetics Industry: It's used for filling aerosol cosmetic products like hair sprays. The automatic line ensures precise filling, meeting high - quality standards for beauty items.

2. Pharmaceutical Field: Ideal for filling aerosol - based pharmaceutical sprays. It enables accurate dosage filling, crucial for medications such as nasal sprays.

3. Automotive Sector: Applies to filling car care aerosol products. For example, it fills spray - on wax or tire shine products with high efficiency.

4. Home Cleaning Products: Used to fill aerosol cleaners. It can handle different types of household cleaners like window sprays and furniture polish sprays.

2. Pharmaceutical Field: Ideal for filling aerosol - based pharmaceutical sprays. It enables accurate dosage filling, crucial for medications such as nasal sprays.

3. Automotive Sector: Applies to filling car care aerosol products. For example, it fills spray - on wax or tire shine products with high efficiency.

4. Home Cleaning Products: Used to fill aerosol cleaners. It can handle different types of household cleaners like window sprays and furniture polish sprays.