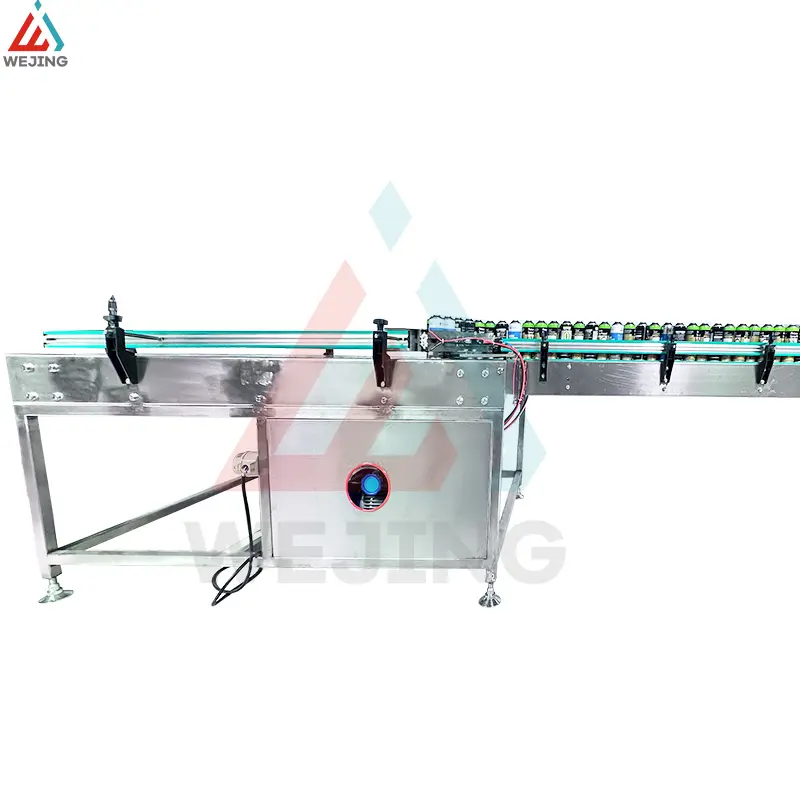

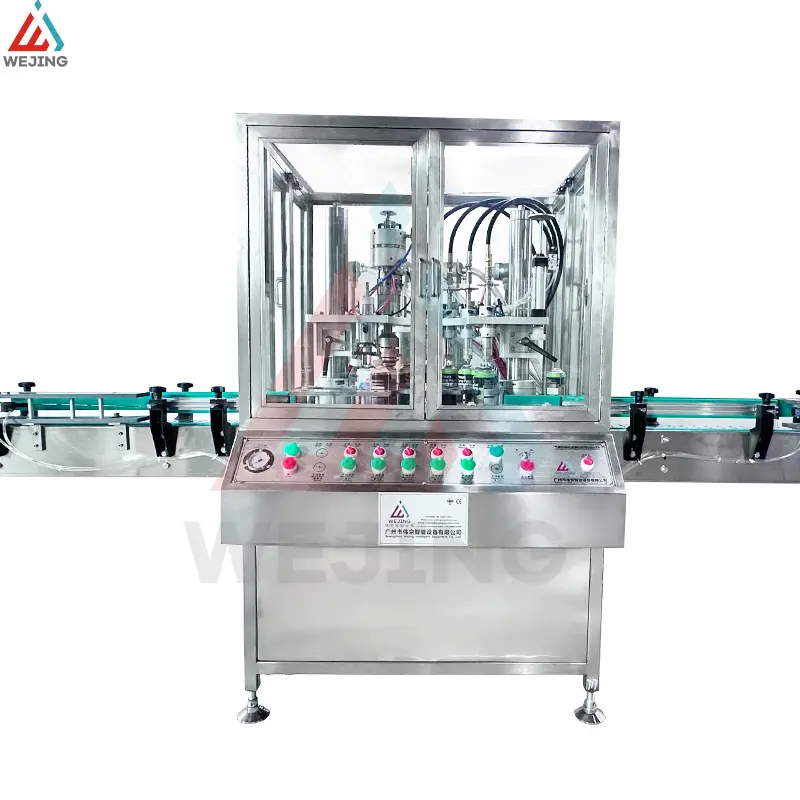

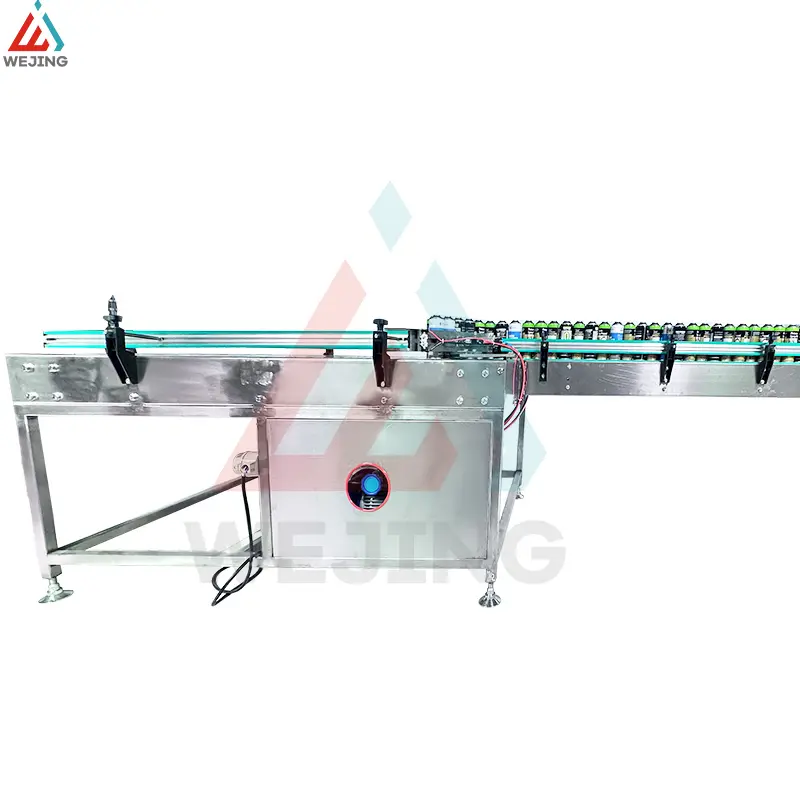

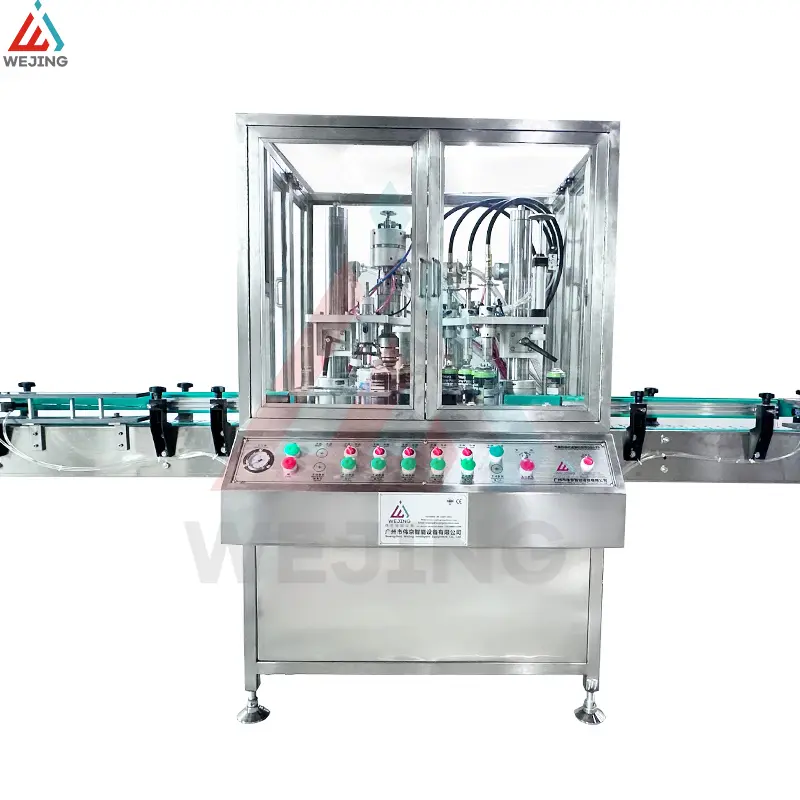

QGJ70 Aerosol Spray Filling Equipment

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

1. Efficient production speed, capable of filling 60 to 70 cans per minute, meeting the needs of medium to large-scale production.

2. Its filling capacity is flexible and adaptable to various specifications of products.

2. Its filling capacity is flexible and adaptable to various specifications of products.

3. Multi station configuration, with four filling heads and inflation heads, enhances parallelism and efficiency, and strengthens equipment stability.

4. Easy to operate and maintain, reducing personnel dependency and costs.

4. Easy to operate and maintain, reducing personnel dependency and costs.

5. High precision control ensures accurate filling, improves product consistency and qualification rate.

6. Good compatibility, adaptable to different specifications of aerosol cans, and strong universality.

6. Good compatibility, adaptable to different specifications of aerosol cans, and strong universality.

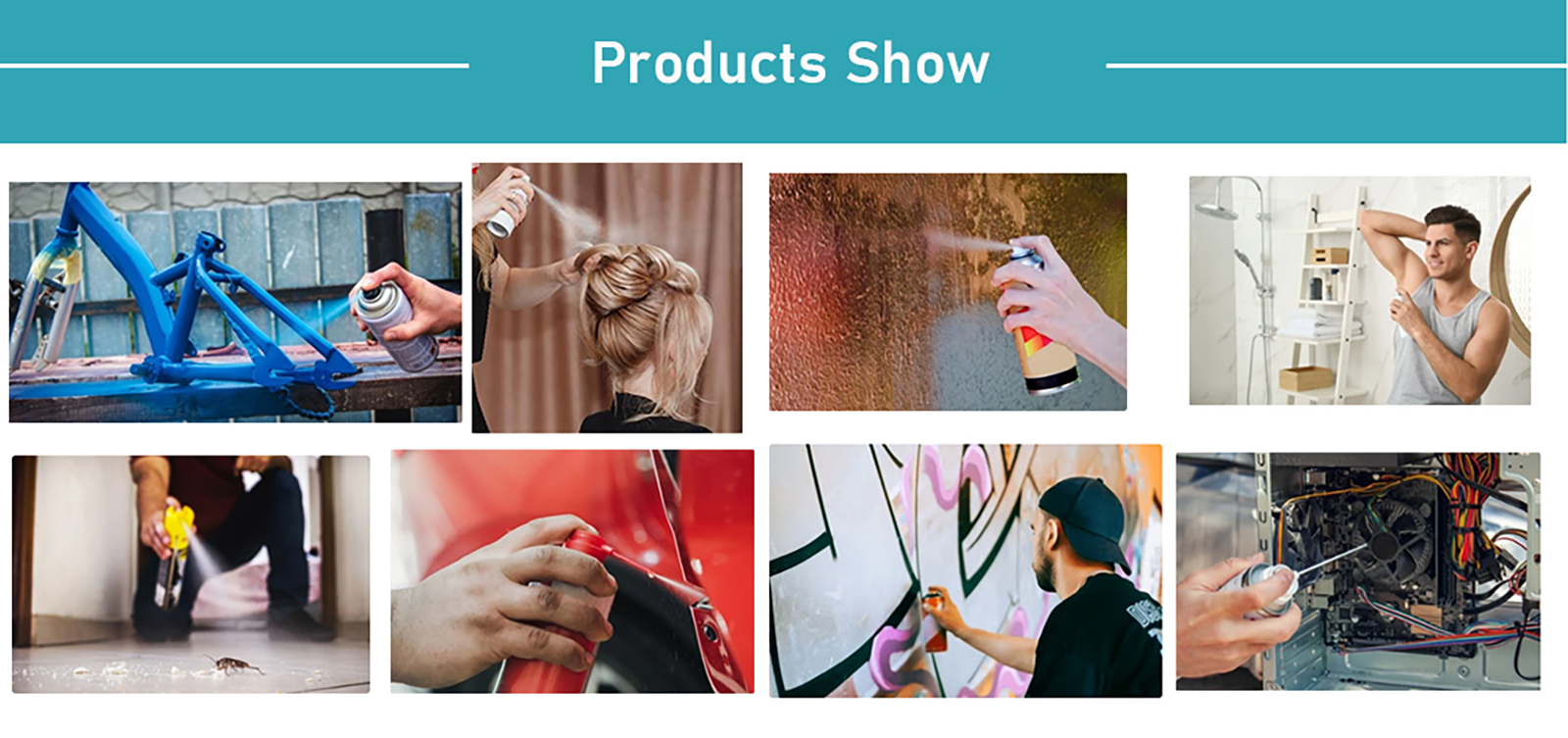

product Applications

1. Products like those in the daily chemical industry, perfume, moisturizing spray and makeup spray.

2. When it comes to medicine, it can be used for certain medical aerosols.

3. For car care products, it can conduct efficient filling for car interior cleaners, tire brighteners and the like.

4. In the industrial field, it's utilized to fill aerosols such as rust - inhibiting agents and lubricants.

2. When it comes to medicine, it can be used for certain medical aerosols.

3. For car care products, it can conduct efficient filling for car interior cleaners, tire brighteners and the like.

4. In the industrial field, it's utilized to fill aerosols such as rust - inhibiting agents and lubricants.

Packing and Delivery

1. Use sturdy materials, cushioning materials, and stretch film on the packaging, fix the components, and label information.

2. Choose reliable companies for transportation, track status in real-time, take protective measures for long-distance transportation, and ensure safe delivery of equipment.

2. Choose reliable companies for transportation, track status in real-time, take protective measures for long-distance transportation, and ensure safe delivery of equipment.

After Sales Service

1. The equipment comes with a 2-years warranty, during which any malfunctions can be repaired free of charge.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.