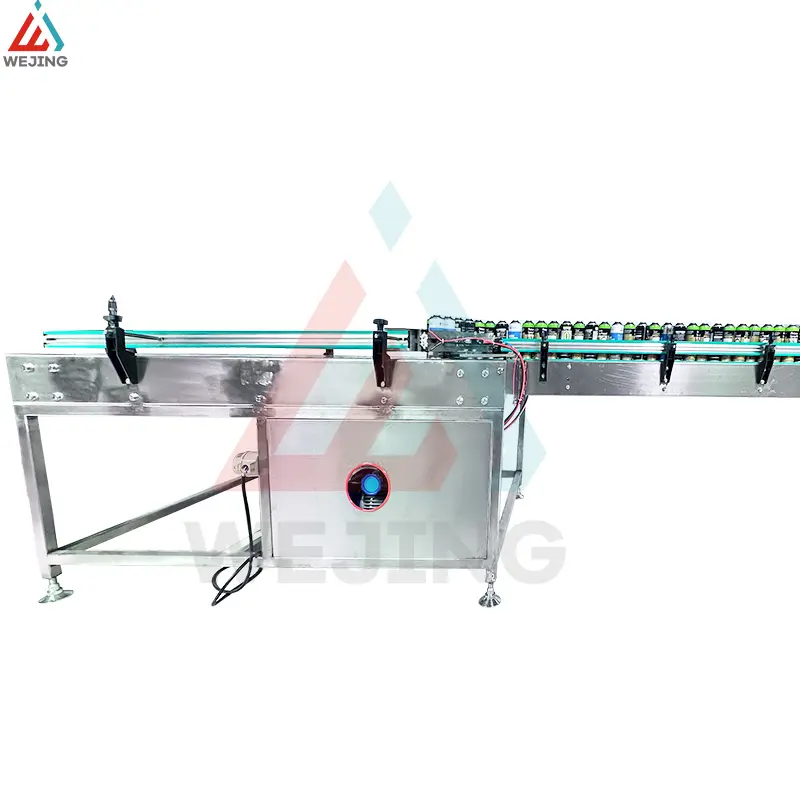

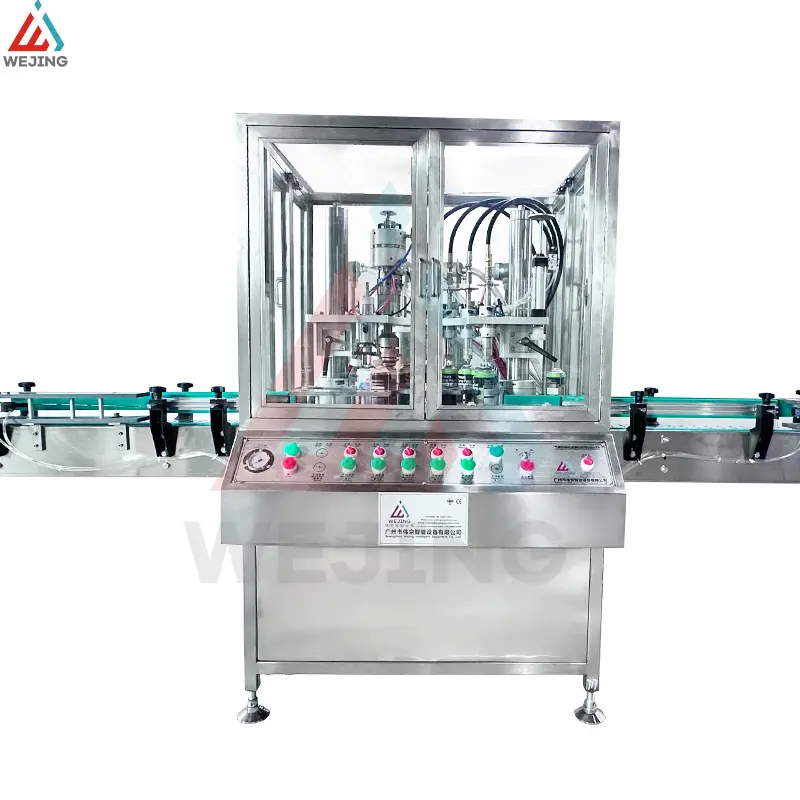

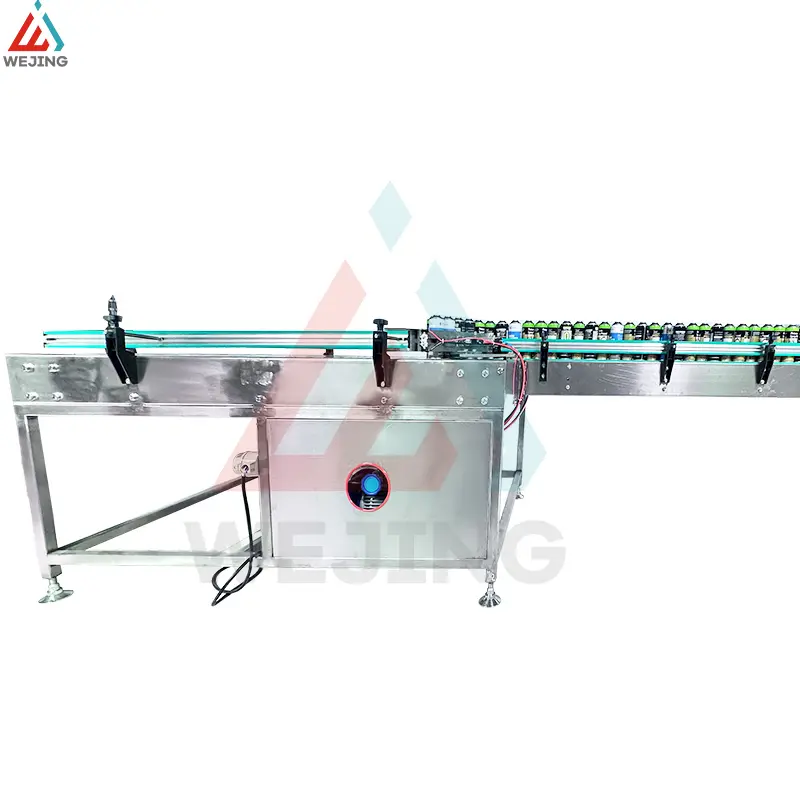

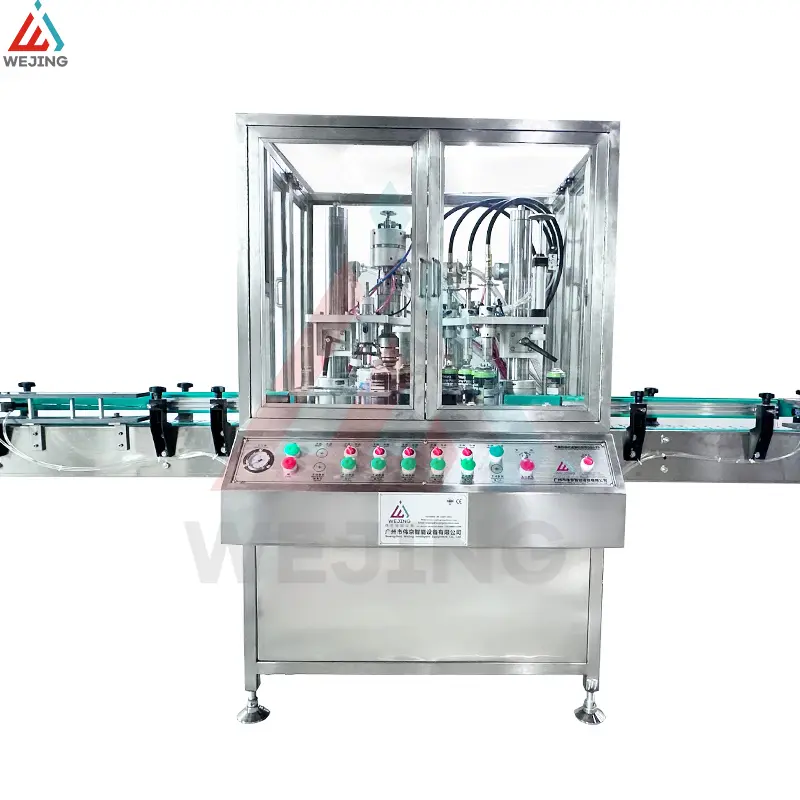

QGJ70 Aerosol Spray Filling Machine Line

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Name |

Description |

|

Filling capacity |

60-70 cans/min |

|

Liquid filling volume |

10-1200 ml ( can be customized) |

|

Gas filling volume |

10-1200ml( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter |

35 - 70mm( can be customized) |

|

Applicable cans height (mm) |

80 - 300mm( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure |

0.6 - 0.8Mpa |

|

Max gas consumption |

5m3/min |

|

Material |

SS304 ( some parts can be SS316) |

|

Power |

7.5KW |

|

Dimension |

22000*3500*2000mm (LWH) |

1. It has an efficient production speed of up to 60 to 70 cans per minute, which can meet the needs of medium to large-scale production and effectively improve production efficiency.

2. It has flexible filling capacity, with individual heads ranging from 10 to 300ml and overall sizes between 10 and 1200ml, which can adapt to a variety of different specifications of products.

2. It has flexible filling capacity, with individual heads ranging from 10 to 300ml and overall sizes between 10 and 1200ml, which can adapt to a variety of different specifications of products.

3. Adopting a multi station configuration with four filling heads and inflation heads, it improves parallelism and efficiency, while also increasing equipment stability.

4. It is very convenient to operate and maintain, which can reduce the dependence on personnel and lower costs.

4. It is very convenient to operate and maintain, which can reduce the dependence on personnel and lower costs.

5. Implement high-precision control to ensure the accuracy of filling volume, improve product consistency and qualification rate.

6. It has good compatibility and can adapt to different specifications of aerosol cans, with strong universality.

6. It has good compatibility and can adapt to different specifications of aerosol cans, with strong universality.

product Applications

1. Daily chemical industry, perfume, moisturizing spray, makeup spray and other products

2. In terms of medicine, it is applicable to some medical aerosols.

3. In car care products, efficient filling can be carried out for car interior cleaning agents, tire brighteners, etc.

4. In the industrial field, it is used for filling aerosols such as rust inhibitors and lubricants.

2. In terms of medicine, it is applicable to some medical aerosols.

3. In car care products, efficient filling can be carried out for car interior cleaning agents, tire brighteners, etc.

4. In the industrial field, it is used for filling aerosols such as rust inhibitors and lubricants.

product FAQ

1.What is the filling speed of QGJ70 fully automatic aerosol filling line?

2.Is the QGJ70 suitable for different aerosol products?

Yes. It has certain flexibility and can be adjusted to handle different types of aerosol products, including those with various formulations and characteristics as long as they fall within the designed operation parameters.

3.How difficult is the operation and maintenance of the QGJ70?

The operation interface of the QGJ70 is designed to be user - friendly. For maintenance, it has a modular structure, which makes it relatively easy to identify and solve problems with the help of professional maintenance personnel and proper training.

4.What safety features does the QGJ70 have?

It is equipped with multiple safety devices. For example, there are sensors to detect abnormal conditions during the filling process. It also has protective enclosures to prevent operators from accidental contact with moving parts.

5.Can the QGJ70 be integrated into an existing production line?

In most cases, it can be integrated. However, some adjustments and compatibility checks might be needed depending on the specific design and requirements of the existing production line. Professional installation and configuration are usually recommended.

The filling speed usually depends on various factors such as product viscosity and container size. Generally, it can achieve a relatively high - speed filling to meet normal production demands within an efficient range.

Yes. It has certain flexibility and can be adjusted to handle different types of aerosol products, including those with various formulations and characteristics as long as they fall within the designed operation parameters.

3.How difficult is the operation and maintenance of the QGJ70?

The operation interface of the QGJ70 is designed to be user - friendly. For maintenance, it has a modular structure, which makes it relatively easy to identify and solve problems with the help of professional maintenance personnel and proper training.

4.What safety features does the QGJ70 have?

It is equipped with multiple safety devices. For example, there are sensors to detect abnormal conditions during the filling process. It also has protective enclosures to prevent operators from accidental contact with moving parts.

5.Can the QGJ70 be integrated into an existing production line?

In most cases, it can be integrated. However, some adjustments and compatibility checks might be needed depending on the specific design and requirements of the existing production line. Professional installation and configuration are usually recommended.

After Sales Service

1. The equipment comes with a 2-years warranty, during which any malfunctions can be repaired free of charge.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.