QGJ70 Air Freshener Aerosol Filling Machine

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Material |

SS304 ( some parts can be SS316) |

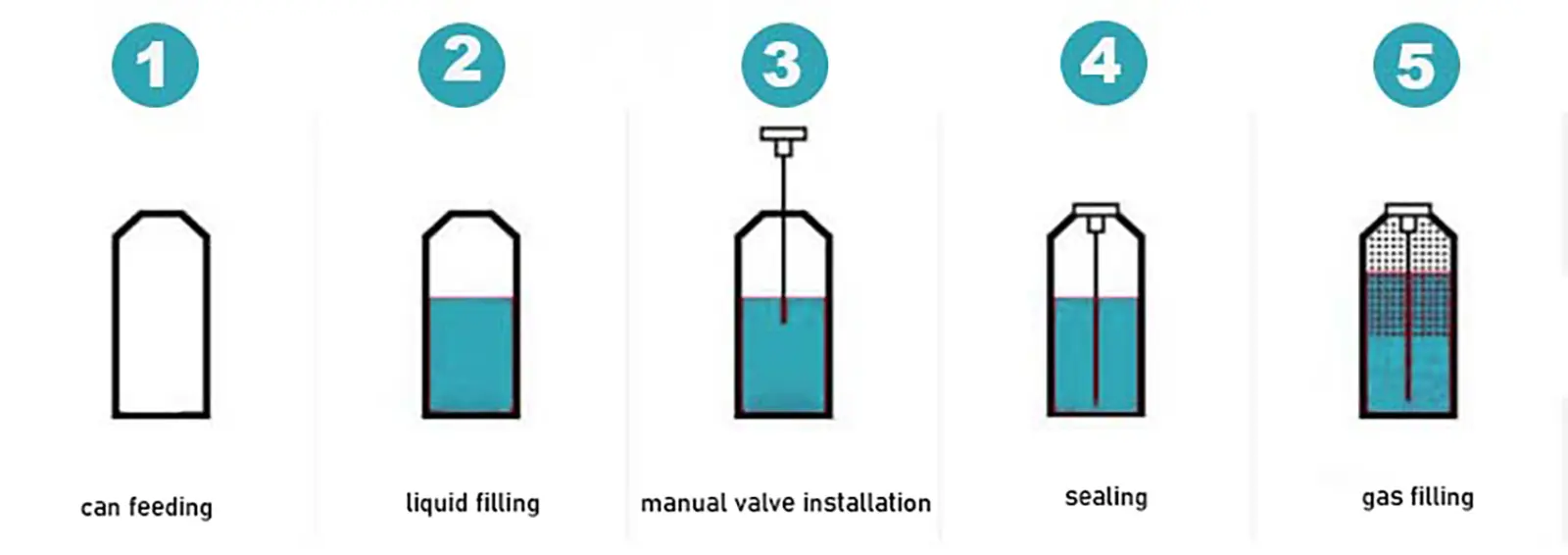

1. Highly automated production:

Enhancing production efficiency: The whole filling line is capable of automatically fulfilling a series of procedures including bottle sorting, filling, valve installation, sealing, inflation, weighing, water inspection, nozzle fastening, and cap fastening. This significantly reduces the steps and time of manual operations. Compared with traditional semi - automatic or manual filling approaches, production efficiency can be enhanced substantially, thus fulfilling the requirements of large - scale production.

2. Compatibility with multiple product specifications: It can be adjusted to different - specification, - shape, and - size aerosol containers and valves. Through simply adjusting and replacing molds and other components, filling and production of various products can be achieved. This meets the diverse production requirements of customers and cuts down the equipment investment cost and production conversion cost for enterprises.

3.Online detection: It is furnished with various online detection devices such as fiber - optic detectors, weighing sensors, water leak detection devices, etc. These can detect in real - time the position of the bottle, the accuracy of the filling amount, the tightness of the seal, and the presence of leaks during the production process.

Can Feeding Machine

Sort out the disordered empty bottles to make them in an orderly state, thus enabling the subsequent filling operations to be carried out smoothly.

Liquid Filling Machine & Valve Insert Machine

Liquid Filling Machine is in charge of filling exact quantities of liquid material into empty bottles. It employs high - precision measuring equipment and filling heads to guarantee that the filling volume of each bottle is accurate and consistent.

Valve Insert Machine mounts the aerosol valve onto the filled bottle. Valves are crucial elements of aerosol products. The valve installation machine can rapidly and precisely install the valve at the bottle opening, guaranteeing the valve's sealing and firm installation, which provides assurance for subsequent inflation and use.

Crimping & Gas Filling

Seal the bottles that have valves installed to further improve their sealing performance and avoid liquid and gas leakage.

Fill a sealed bottle with a particular gas, which is generally utilized as a propellant to spray the liquid inside the bottle in a misty form.

Auto Actuator Fixed Machine

Mount the nozzle onto the valve of the bottle, enabling users to spray liquid in a mist conveniently.

Capping Machine

Applying an outer cover to aerosol products plays a role in protecting the valve, nozzle, and the body of the bottle.

Inkjet Belt

Spray-printing information such as production date, batch number, expiration date, and others on the bottle or packaging of aerosol products to facilitate product traceability and management.

Another version: Conduct spray printing of production date, batch number, expiration date, and other details on the bottle or packaging of aerosol products so as to make product traceability and management easier.

product Applications

product faq

A: Regular maintenance involves cleaning the machine, inspecting and replacing worn parts, and ensuring proper lubrication. For specific maintenance guidelines, please refer to the manufacturer's manual.