QGJ70 Automatic Aerosol Filling Line

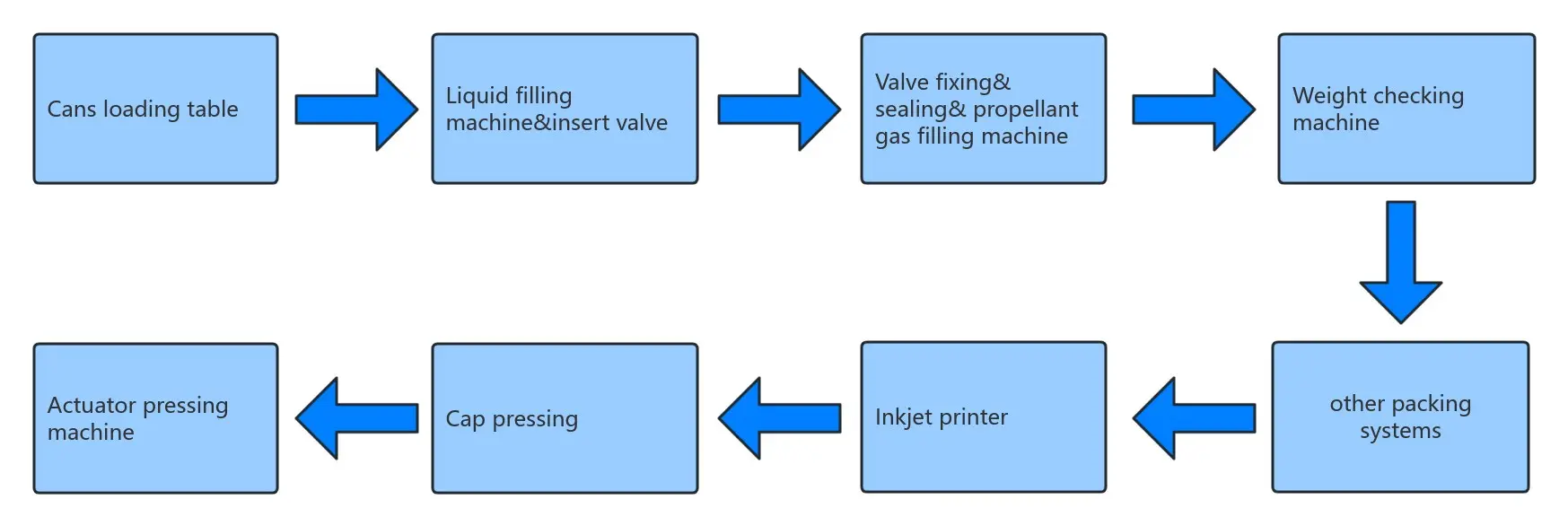

An Automatic weight verifier checks the filled cans, a water immersion station tests for leaks, a nozzle applicator attaches the nozzles, a cap sealer secures the caps, an inkjet labeling device labels the products, and there are also multiple packaging stations. These systems are compatible with numerous propellants like LPG, DME, CO2, N2, and compressed air. They are widely utilized in various products, including spray paints for surface coating, air fresheners to make the environment smell pleasant, insecticides to eliminate pests, body mists for personal fragrance, cosmetic formulations for beauty enhancement, and food-grade aerosols for edible applications.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

|

Warranty |

1 year |

|

Key Selling Points |

High speed fully automatic high production |

|

Maintenance Requirements |

Recommended maintenance procedures and schedules |

|

Certifications and Standards |

CE&ISO9001 |

Working Princeple

The fully automatic aerosol filling machine line is composed of several essential components. The cans feeding machine is responsible for the orderly supply of cans. The rotary liquid filling machine precisely dispenses the liquid substances. The rotary sealing and gas filling machine undertakes the tasks of sealing and injecting various gases. The automatic weight checker verifies the weight of the filled products. The nozzle presser machine attaches the nozzles firmly. The capping machine seals the tops. The inkjet printer imprints necessary information. And the packing table is where the final packaging process takes place. When it comes to propellants, options such as LPG, DME, CO2, N2, and compressed air are available. These aerosol filling systems find extensive usage in a broad spectrum of products, namely spray paint for surface decoration, air freshener to improve the ambient air quality, insecticide to combat pests, body spray for personal fragrance, cosmetics for enhancing appearance, and food aerosols for edible applications.

Why Choose us

1. Quality Assurance: The machine, made of stainless S304, features a unique design. It meets contract quality, spec, and function norms. A one-year-plus warranty is provided.

2. Training: We offer customers tech training via online videos on equipment structure, upkeep, and operation. Skilled techs oversee it. Post-training, buyer's techs can handle machine ops, maintenance, process tweaks, and fault fixes.

3. Customization: Machines can be tailored to customer needs.

4. Cosmetics Support: We help with the full daily cosmetics production, from raw materials and packaging to decoration machines.

5. Tech Aid: Our pro engineers are on standby for machine installation and maintenance help.

6. Swift Response: Our 24/7 sales team answers machine queries promptly and solves them within 12 hours.

7. Formulation & More: We assist with formulation, packaging, and raw material aspects.

8. Pre-order Testing: The machine can be tried before ordering.

2. Training: We offer customers tech training via online videos on equipment structure, upkeep, and operation. Skilled techs oversee it. Post-training, buyer's techs can handle machine ops, maintenance, process tweaks, and fault fixes.

3. Customization: Machines can be tailored to customer needs.

4. Cosmetics Support: We help with the full daily cosmetics production, from raw materials and packaging to decoration machines.

5. Tech Aid: Our pro engineers are on standby for machine installation and maintenance help.

6. Swift Response: Our 24/7 sales team answers machine queries promptly and solves them within 12 hours.

7. Formulation & More: We assist with formulation, packaging, and raw material aspects.

8. Pre-order Testing: The machine can be tried before ordering.