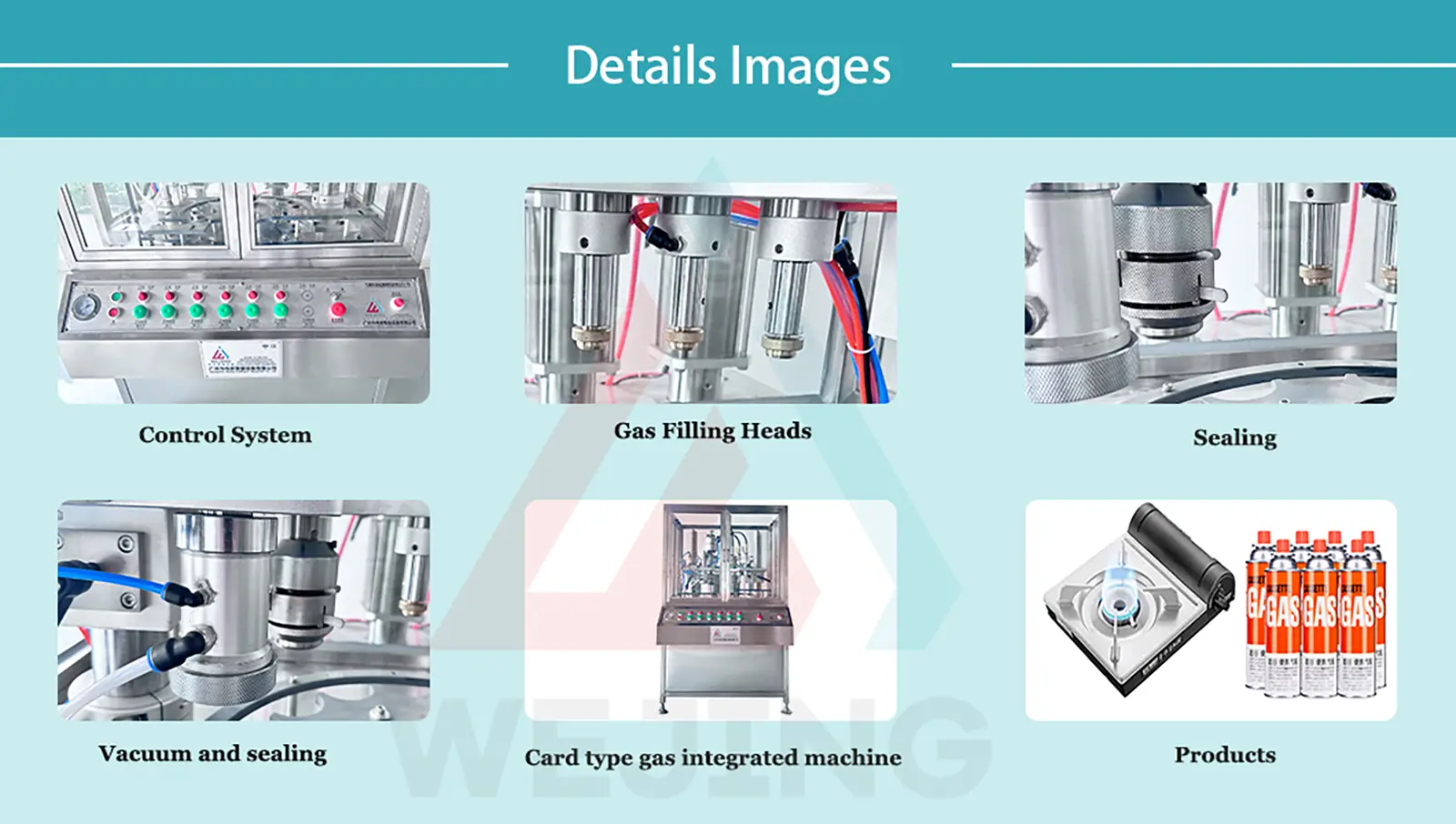

QGJ70 Cartridge Gas Filling Machine

The design of fully automatic card type gas mist filling machine usually considers the compatibility of different specifications of card type gas cylinders, which can adapt to various sizes of tank bodies. In addition, it also emphasizes the reliability and durability of equipment to meet long-term high-intensity production needs.

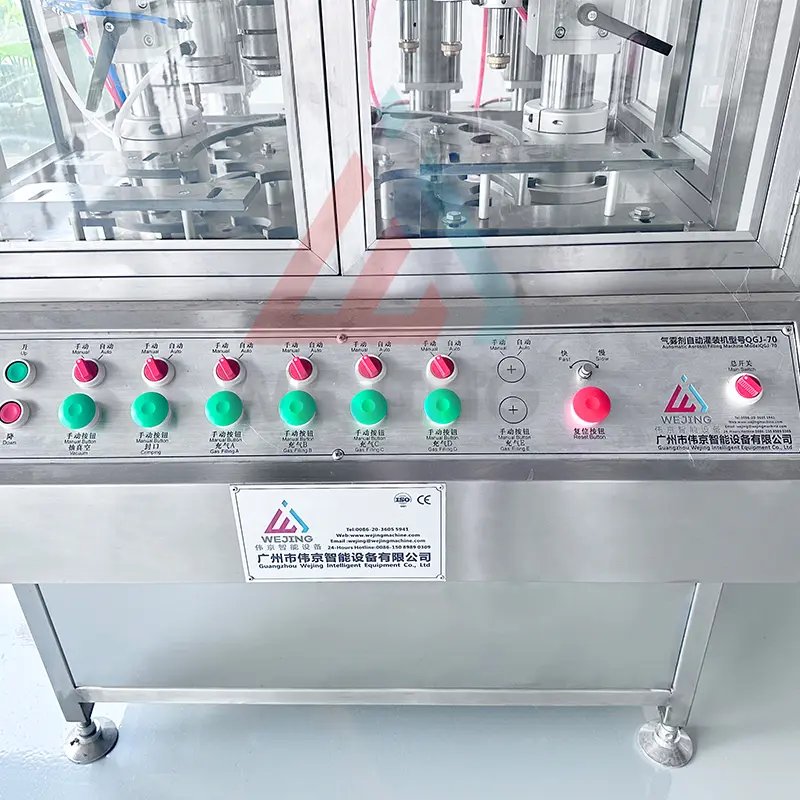

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Model Number |

QGJ70 |

|

Place of Origin |

Guangdong |

|

Certification |

CE&ISO9001 |

|

Supply Ability |

10sets per month |

|

Production speed |

60-70 cans / min |

|

Capacity |

30-750ml ( Can Be Customized) |

|

Speed |

High |

|

Gas consumption |

6.5m 3/ Min |

Working Process

1. The canisters enters the filling machine.2. Vacuum treat the container through a vacuum port to remove air impurities.

3. Perform sealing operation to ensure good sealing performance.

4. Four filling heads work simultaneously to fill the container with gas from the ink cartridge, precisely controlling the filling amount.

5. Loaded canisters to the next process.

Product Advantages

1. Highly automated: Automatically complete filling to improve efficiency.2. Accurate measurement: Ensure accurate filling volume and improve product quality.

3. Easy to operate: reduce the difficulty of operation and minimize errors.

4. Strong compatibility: Suitable for filling card type gas containers of different specifications and shapes

5. Reliable and durable: capable of withstanding high-intensity production and reducing costs.

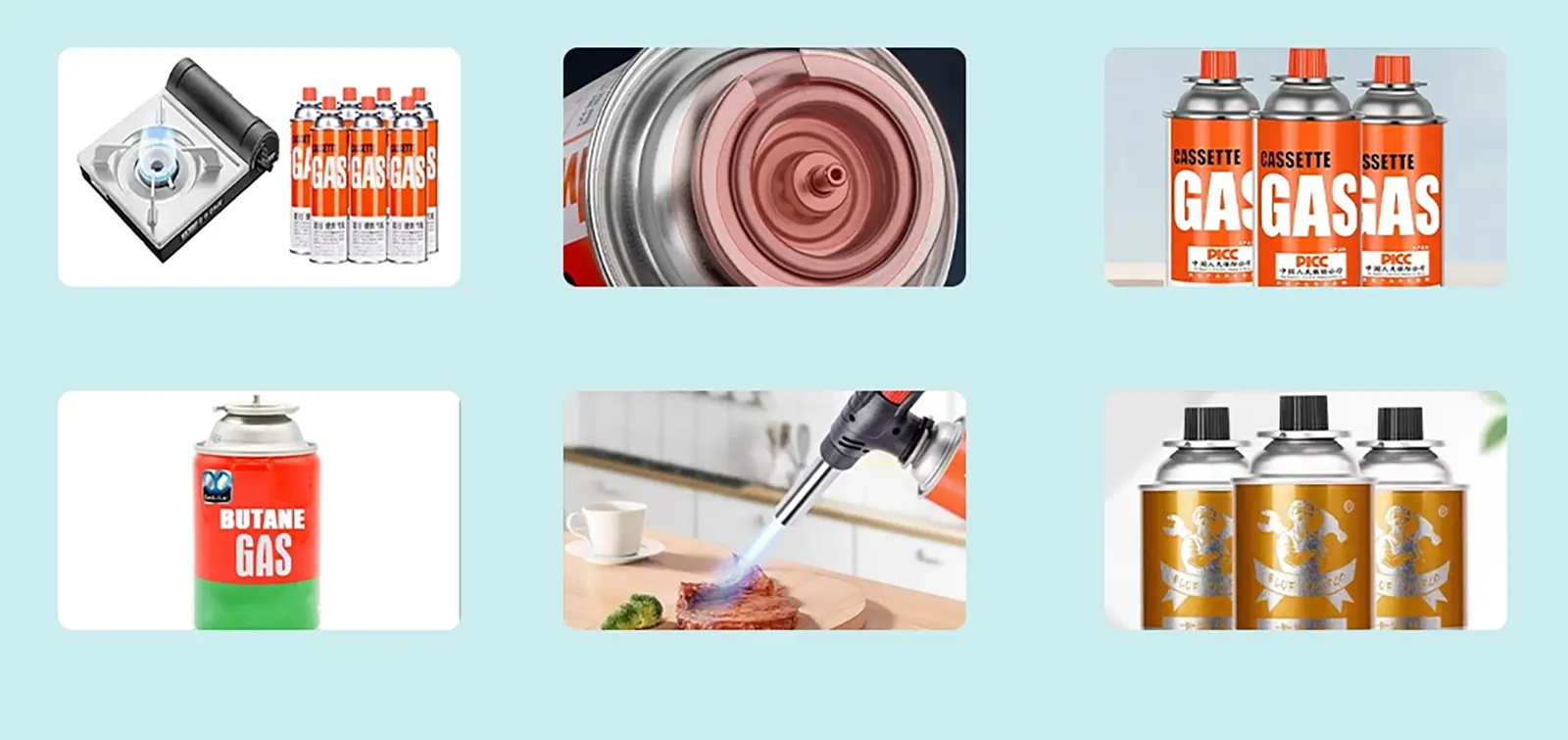

product Applications

Used for filling various card type gas products, such as portable butane gas cylinders, to meet the needs of outdoor cooking, heating and other scenarios.

Packing and Delivery

1. Use sturdy materials, cushioning materials, and stretch film on the packaging, fix the components, and label information.

2. Choose reliable companies for transportation, track status in real-time, take protective measures for long-distance transportation, and ensure safe delivery of equipment.

2. Choose reliable companies for transportation, track status in real-time, take protective measures for long-distance transportation, and ensure safe delivery of equipment.

After Sales Service

1. The equipment comes with a 2-years warranty, during which any malfunctions can be repaired free of charge.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.

2. Provide professional training covering operation and maintenance to ensure that customers can use the equipment correctly.

3. Regularly follow up with customers to understand the operation status of the equipment and promptly address any issues.

4. Quick response to fault repairs, remote guidance or on-site service can be provided to ensure stable equipment operation, so that customers do not have to worry and can fully invest in production, thereby improving production efficiency and product quality.