QGJ70 Snow Spray Paint Filling Machine

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Technical Parameter |

Description |

|

Filling capacity (cans/min) |

60-70 |

|

Liquid filling volume (ml) |

10-1200( can be customized) |

|

Gas filling volume (ml) |

10-1200( can be customized) |

|

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter (mm) |

35 - 70( can be customized) |

|

Applicable cans height (mm) |

80 - 300( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure (Mpa) |

0.6 - 0.8 |

|

Max gas consumption (m3/min) |

5 |

|

Power (KW) |

7.5 |

|

Dimension (LWH) mm |

22000*3500*2000 |

|

Material |

SS304 ( some parts can be SS316) |

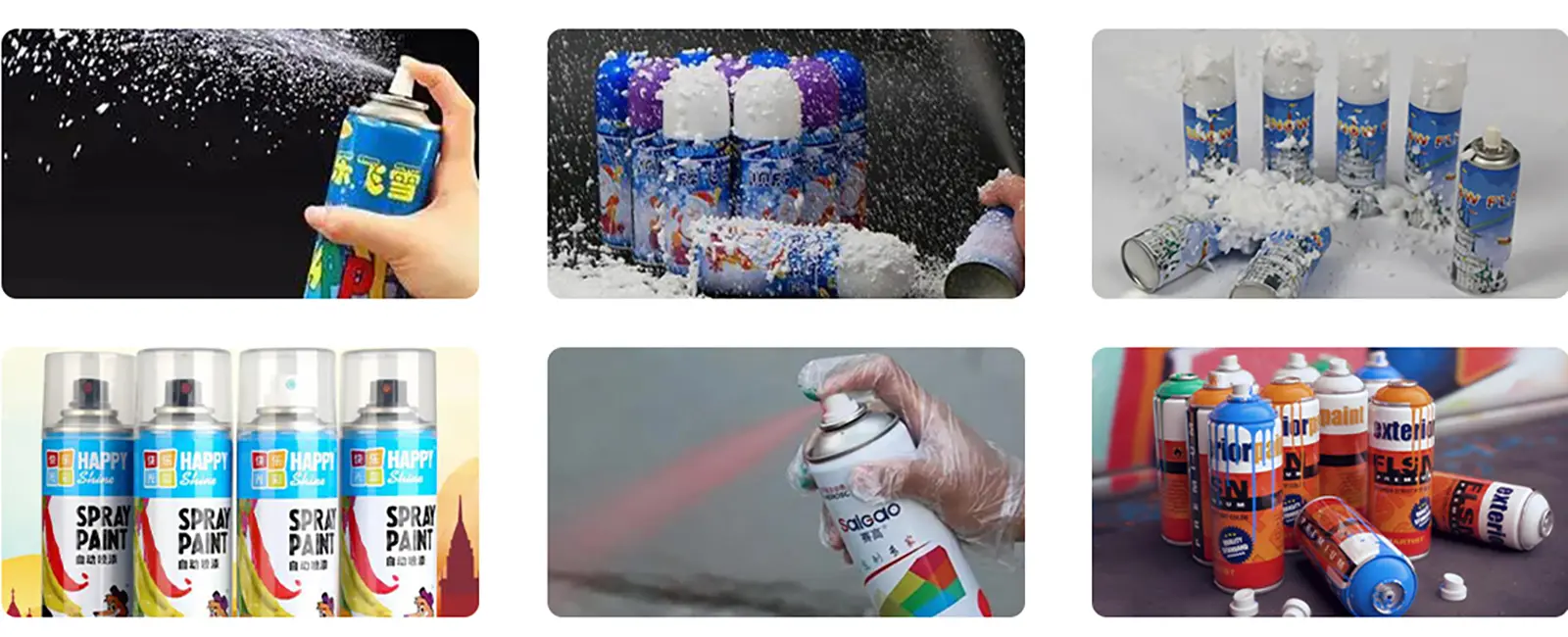

product Applications

1. Automotive maintenance industry. It is used for car spray painting and canning. When combined with a glass bead machine, it ensures uniform spraying, which is convenient for repairing paint scratches and other problems.

2. In the home decoration field. It can be filled with various decorative spray paints to meet the requirements of furniture renovation, wall graffiti, etc., and the operation is convenient and efficient.

3. In industrial manufacturing. It provides filling services for industrial spray painting to ensure the stability of product quality and enhance production efficiency.

4.In artistic creation scenarios. It is suitable for filling artistic spray paints, helping artists to realize their creativity, and the glass bead machine makes the spray painting effect more remarkable.

Our Service:

1. As a direct manufacturer, your complete satisfaction is our top priority.

2. Logo printing: Any logo you require can be printed on the case by us.

3. We handle each order throughout the entire process, and all emails will be replied to within one day.

4. Regardless of your order quantity, we will maintain the same level of quality and service.

5. Delivery & lead time: All delivery options are acceptable, and our lead time is very short. Generally, it's around 7 - 15 days, depending on the quantity.

6. Packages: Wooden cases and carton boxes are available.

2. In the home decoration field. It can be filled with various decorative spray paints to meet the requirements of furniture renovation, wall graffiti, etc., and the operation is convenient and efficient.

3. In industrial manufacturing. It provides filling services for industrial spray painting to ensure the stability of product quality and enhance production efficiency.

4.In artistic creation scenarios. It is suitable for filling artistic spray paints, helping artists to realize their creativity, and the glass bead machine makes the spray painting effect more remarkable.

Our Service:

1. As a direct manufacturer, your complete satisfaction is our top priority.

2. Logo printing: Any logo you require can be printed on the case by us.

3. We handle each order throughout the entire process, and all emails will be replied to within one day.

4. Regardless of your order quantity, we will maintain the same level of quality and service.

5. Delivery & lead time: All delivery options are acceptable, and our lead time is very short. Generally, it's around 7 - 15 days, depending on the quantity.

6. Packages: Wooden cases and carton boxes are available.

product faq

Q: Can this machine handle aerosol cans of diverse sizes and shapes?

Q: Is the machine compatible with distinct types of aerosol products, like flammable or corrosive ones?

Q: How straightforward is it to change the settings for different aerosol products?

Q: Can the machine detect and reject cans with faulty or incomplete nozzle pressing?

Q: What kind of maintenance is required for the machine?

A: Regular maintenance involves cleaning the machine, inspecting and replacing worn parts, and ensuring proper lubrication. For specific maintenance guidelines, please refer to the manufacturer's manual.

A: Indeed, this machine is engineered to deal with aerosol cans of various sizes and shapes, offering flexibility for different product demands.

A: Yes, this machine is designed to handle various kinds of aerosol products, including flammable, corrosive, and non-flammable items, ensuring safe and efficient nozzle suppression.

A: The machine features a user-friendly interface that enables operators to easily modify settings for different aerosol products, including nozzle pressure and speed.

A: Yes, the machine is equipped with sensors to identify nozzle pressing defects or incompleteness. It can automatically reject such cans to ensure that only products with proper sealing can continue on the filling line.

A: Regular maintenance involves cleaning the machine, inspecting and replacing worn parts, and ensuring proper lubrication. For specific maintenance guidelines, please refer to the manufacturer's manual.