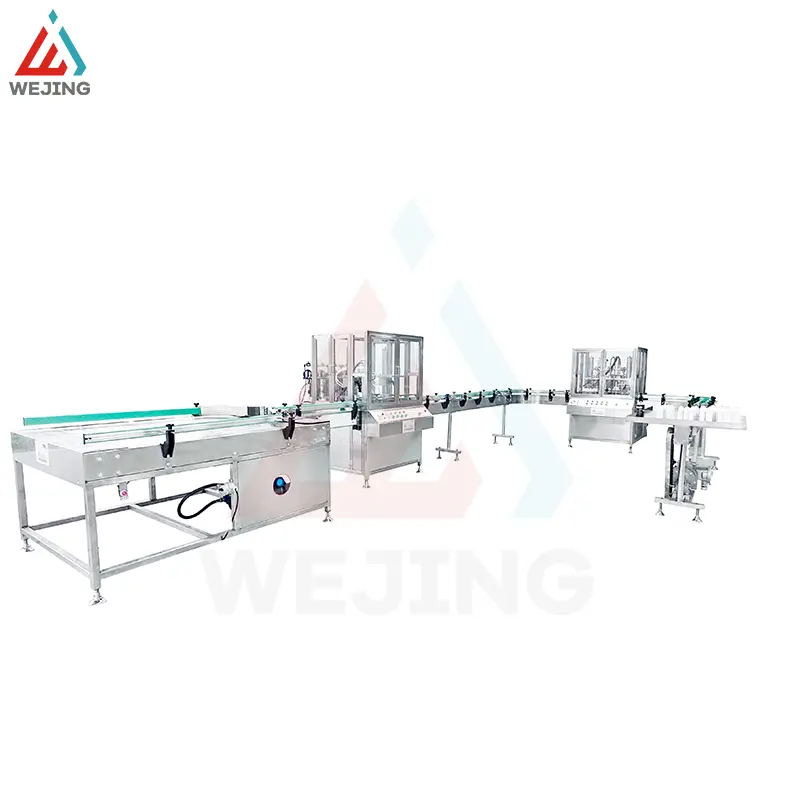

QGJ70 U Shaped Aerosol Filling Line

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Name |

Description |

|

Filling capacity |

60-70 cans/min |

|

Liquid filling volume |

10-1200 ml ( can be customized) |

|

Gas filling volume |

10-1200ml( can be customized) |

|

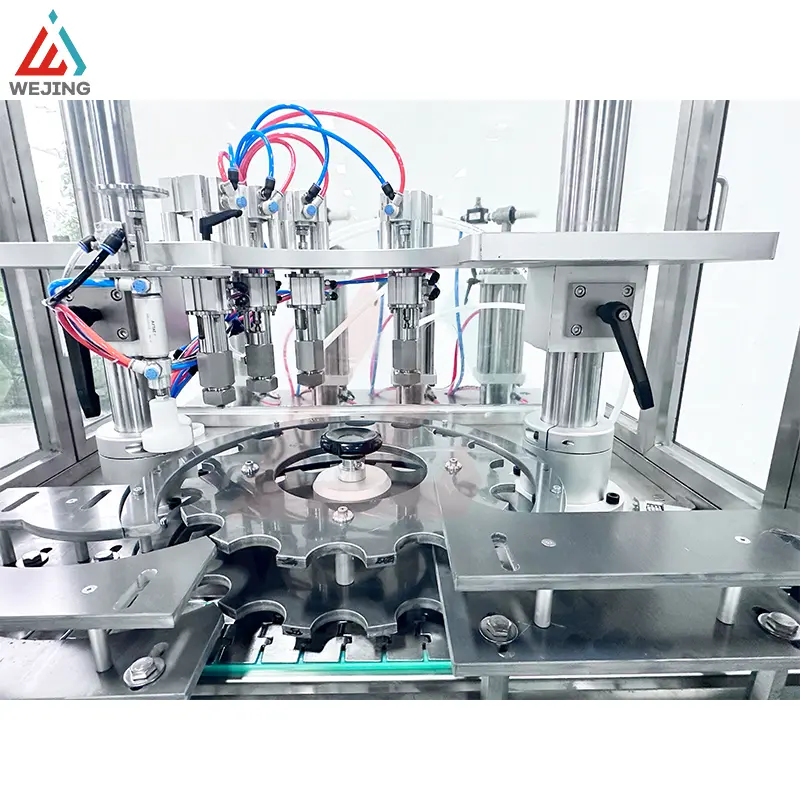

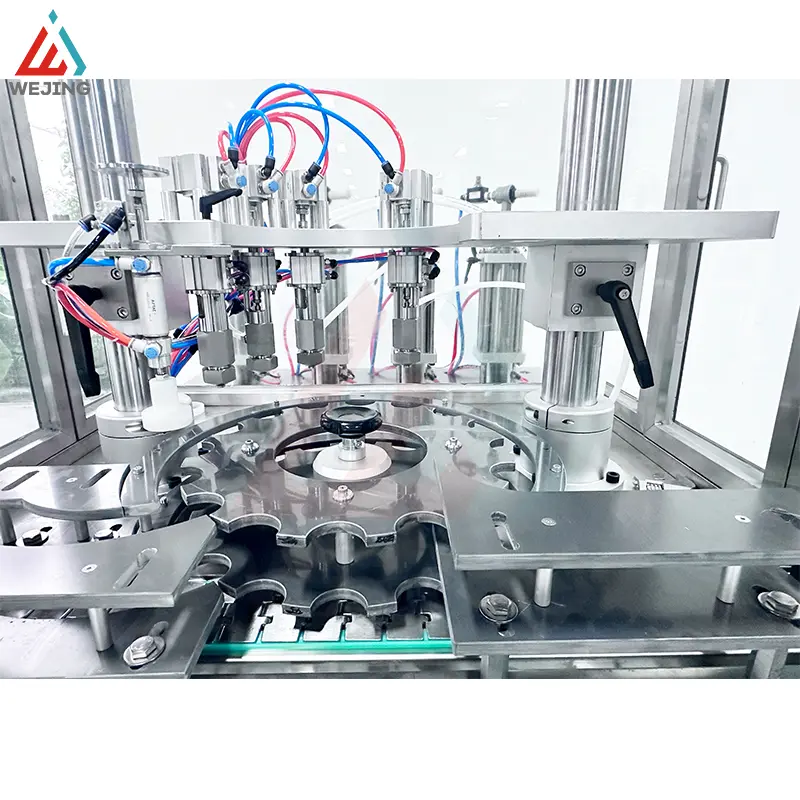

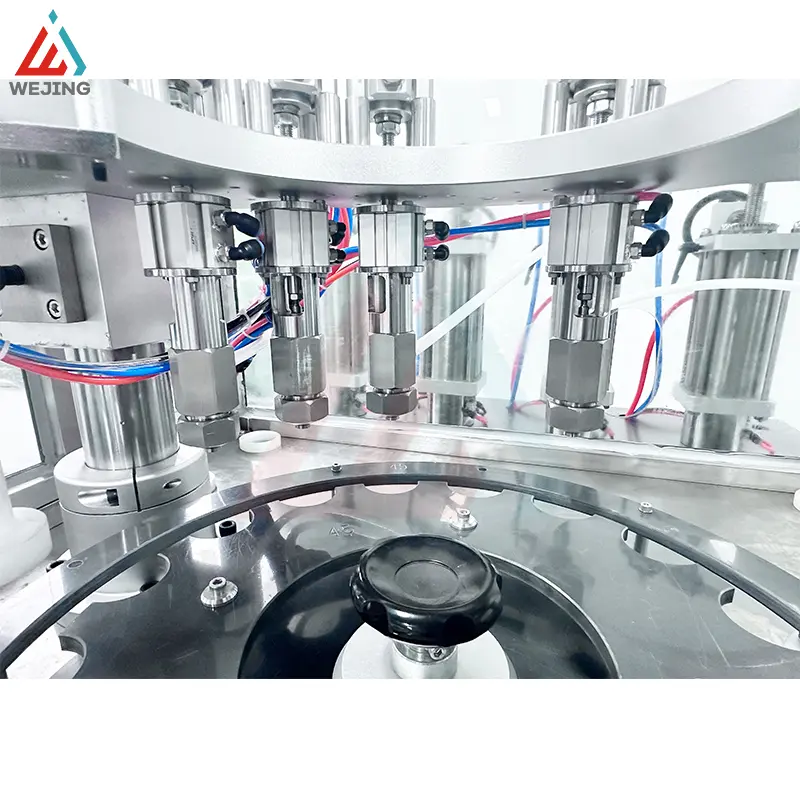

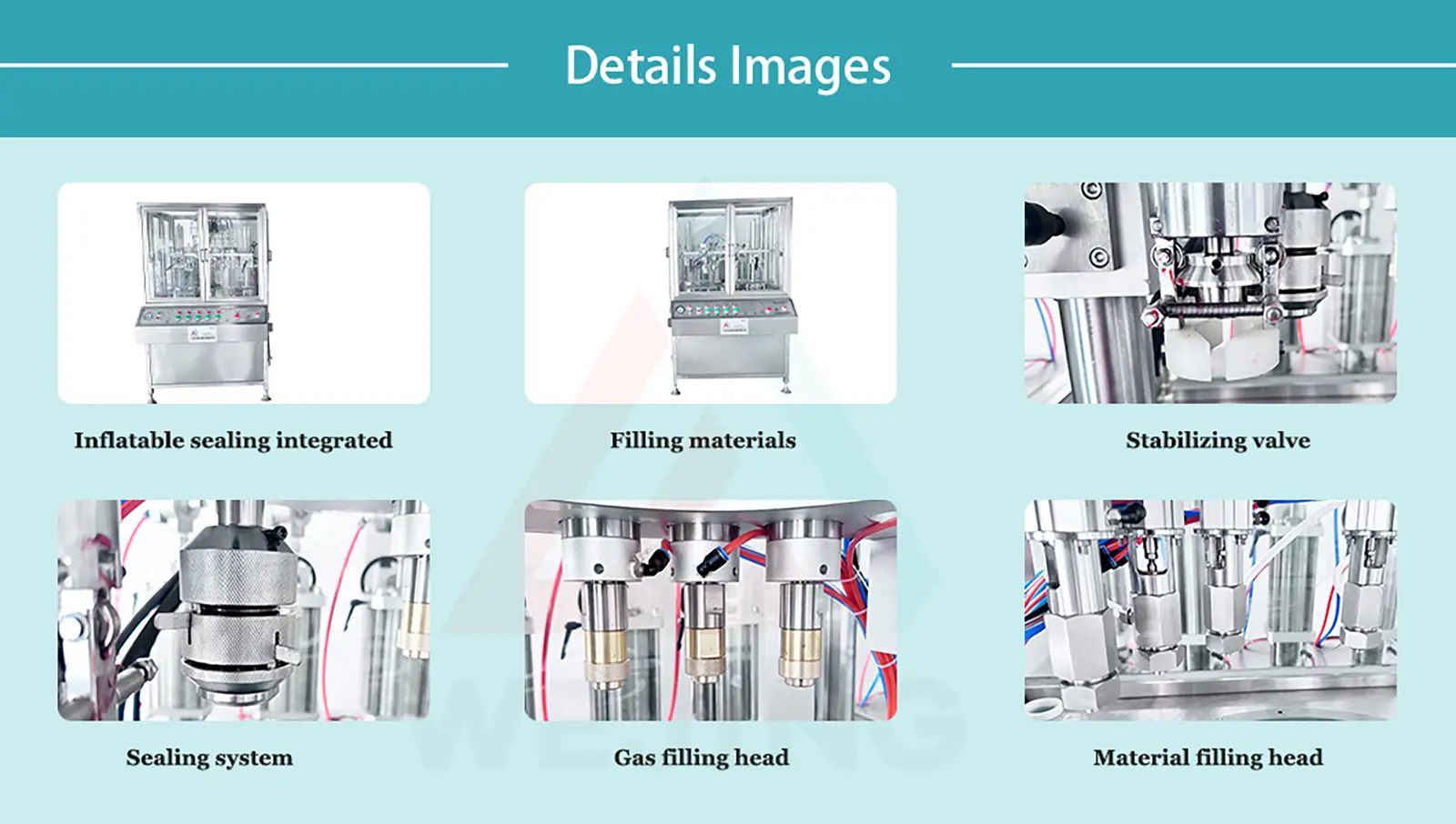

Filling heads |

4 heads |

|

Filling accuracy |

≤±1% |

|

Applicable cans diameter |

35 - 70mm( can be customized) |

|

Applicable cans height (mm) |

80 - 300mm( can be customized) |

|

Applicable valve |

1 inch |

|

Working pressure |

0.6 - 0.8Mpa |

|

Max gas consumption |

5m3/min |

|

Material |

SS304 ( some parts can be SS316) |

|

Power |

7.5KW |

|

Dimension |

22000*3500*2000mm (LWH) |

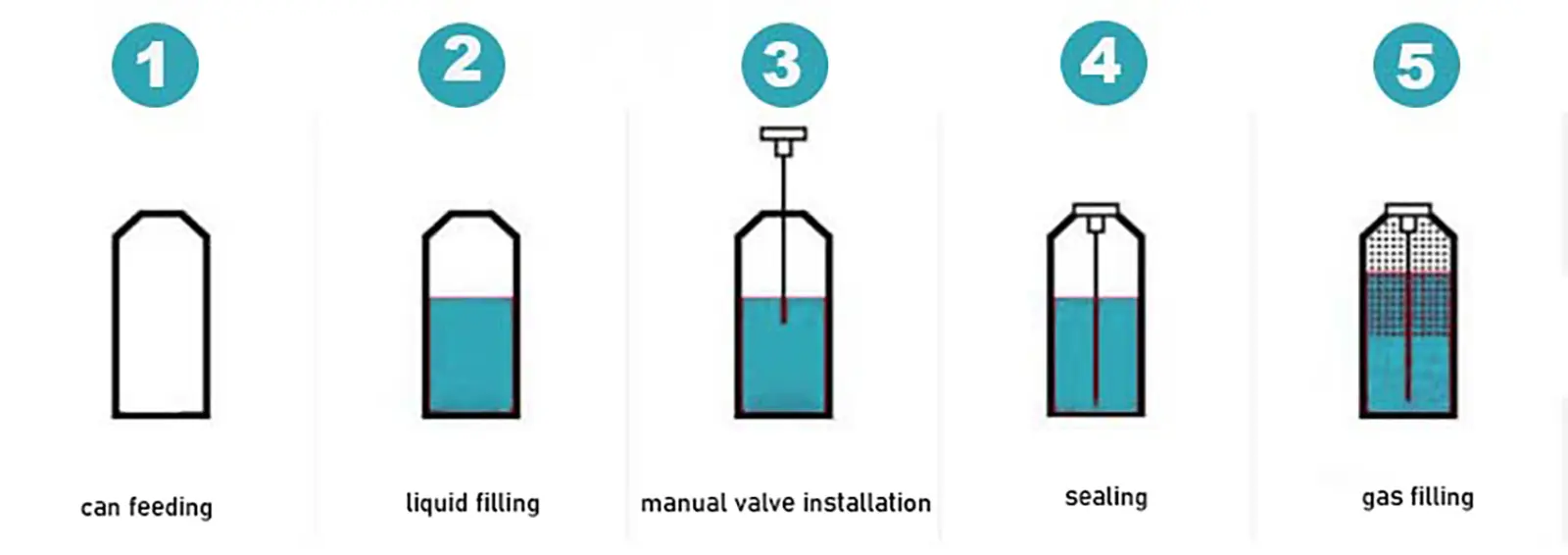

Product Characteristics

1. Efficiency: Fully automated process, quickly completing each link, improving production efficiency.

2. Precision: Accurately control the filling volume and pressure to ensure consistent product quality.

3. Reliable: Real time monitoring to ensure quality, good sealing to prevent leakage.

4. Flexibility: Suitable for tanks of different specifications, easy to adjust manually on the valve.

5. Intelligence: It has the function of not working without bottles, avoiding ineffective operations and saving energy and resources.

2. Precision: Accurately control the filling volume and pressure to ensure consistent product quality.

3. Reliable: Real time monitoring to ensure quality, good sealing to prevent leakage.

4. Flexibility: Suitable for tanks of different specifications, easy to adjust manually on the valve.

5. Intelligence: It has the function of not working without bottles, avoiding ineffective operations and saving energy and resources.

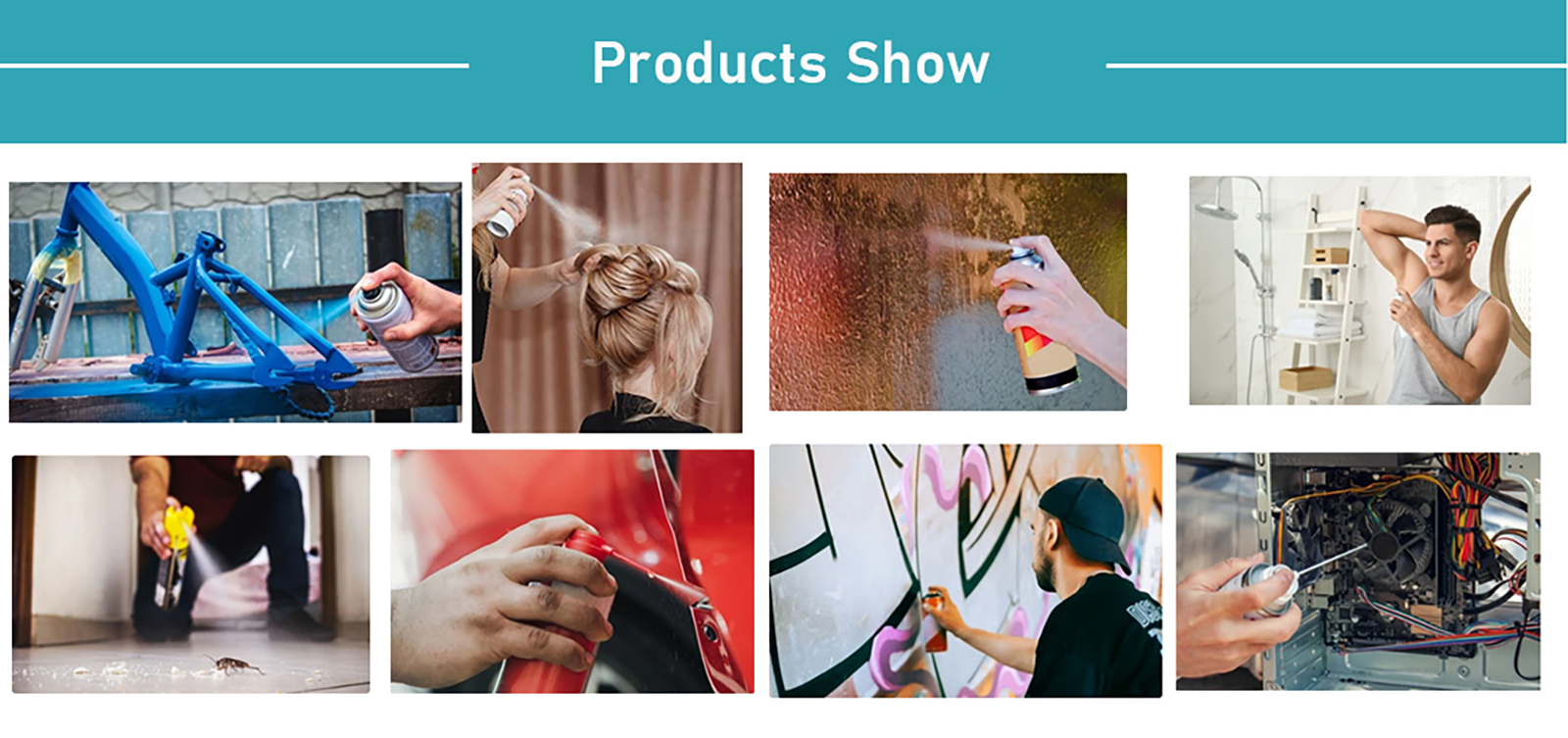

product Applications

1.Daily chemical industry

It is widely used in the production of products such as perfumes, hairsprays, and air fresheners. These products require precise filling volumes and seals. The machine line can efficiently complete the production, ensure product quality and use safety, meet the needs of large-scale production, and ensure that each aerosol can meet the standard.

2.Pharmaceutical industry

Used for filling medicinal aerosols, such as asthma sprays. It can accurately fill the drug dose, ensure the stability of the drug in the aerosol, and operate in a sterile environment to prevent the drug from being contaminated, which is crucial for the health of patients.

3.Food industry

For filling food aerosols such as cream sprays and edible oil sprays. It can operate in accordance with strict hygiene standards and precisely control the filling volume to keep the product in good condition in the packaging and ensure the freshness and safety of food.

4.Industrial field

For the production of aerosols such as lubricating oils and rust inhibitors. The machine line can adapt to liquids of different viscosities, ensure a smooth filling process, and quickly complete the filling of a large number of products, improving production efficiency and meeting the large demand of industrial production.

It is widely used in the production of products such as perfumes, hairsprays, and air fresheners. These products require precise filling volumes and seals. The machine line can efficiently complete the production, ensure product quality and use safety, meet the needs of large-scale production, and ensure that each aerosol can meet the standard.

2.Pharmaceutical industry

Used for filling medicinal aerosols, such as asthma sprays. It can accurately fill the drug dose, ensure the stability of the drug in the aerosol, and operate in a sterile environment to prevent the drug from being contaminated, which is crucial for the health of patients.

3.Food industry

For filling food aerosols such as cream sprays and edible oil sprays. It can operate in accordance with strict hygiene standards and precisely control the filling volume to keep the product in good condition in the packaging and ensure the freshness and safety of food.

4.Industrial field

For the production of aerosols such as lubricating oils and rust inhibitors. The machine line can adapt to liquids of different viscosities, ensure a smooth filling process, and quickly complete the filling of a large number of products, improving production efficiency and meeting the large demand of industrial production.

Packing and Delivery

1. Careful protective packaging: First, fix the machine with stretch film, and then use wooden boxes for all-round protection to ensure that it is not damaged during transportation.

2. Efficient transportation services: Based on customer needs and product characteristics, we provide a variety of transportation options, such as land, sea, air, etc., to meet different transportation time and cost requirements

2. Efficient transportation services: Based on customer needs and product characteristics, we provide a variety of transportation options, such as land, sea, air, etc., to meet different transportation time and cost requirements