Semi Auto Aerosol Gas Filling Machine

Automatic Bag On Valve Aerosol Filling MachinePRODUCT PARAMETERS

|

Filling volume |

30-500ml (customized) |

|

Filling accuracy |

≤±1% |

|

Filling capacity |

500-1000 Can/hr |

|

Can height |

70-330mm,customization available |

|

Can size |

1 inch |

|

Air source |

0.45-0.7Mpa |

|

Air consumption |

0.8m3/min |

|

Weight |

320kg |

|

Dimension |

840*550*1760mm |

Automatic Bag On Valve Aerosol Filling MachineWorking Process

1. Container preparation: Clean and dry empty aerosol cans or other gas packaging containers to ensure that the interior of the container is clean, free of impurities and moisture, in order to ensure the purity and quality of the gas. For example, for some moisture sensitive gases, the moisture content inside the container must be strictly controlled at an extremely low level.

2. Gas transportation: Transport the gas to be filled through pipelines or other conveying devices to the gas inlet of the filling machine. During the transportation process, it is necessary to ensure stable gas pressure and accurate flow rate to ensure the accuracy and consistency of filling. For example, using a pressure regulator to stabilize the pressure of gas.

3. Filling operation: The operator places the pre processed container on the filling position of the filling machine and starts the filling machine for gas filling. The filling machine accurately fills the gas into the container according to the set filling volume. During the filling process, it is necessary to monitor the filling volume in real-time to ensure that the filling volume of each container meets the requirements.

4. Quality inspection: Conduct quality inspection on the filled gas container, including checking the sealing of the container, whether the filling amount is accurate, and whether the purity of the gas meets the requirements. For non-conforming products, corresponding measures need to be taken, such as refilling or scrapping.

2. Gas transportation: Transport the gas to be filled through pipelines or other conveying devices to the gas inlet of the filling machine. During the transportation process, it is necessary to ensure stable gas pressure and accurate flow rate to ensure the accuracy and consistency of filling. For example, using a pressure regulator to stabilize the pressure of gas.

3. Filling operation: The operator places the pre processed container on the filling position of the filling machine and starts the filling machine for gas filling. The filling machine accurately fills the gas into the container according to the set filling volume. During the filling process, it is necessary to monitor the filling volume in real-time to ensure that the filling volume of each container meets the requirements.

4. Quality inspection: Conduct quality inspection on the filled gas container, including checking the sealing of the container, whether the filling amount is accurate, and whether the purity of the gas meets the requirements. For non-conforming products, corresponding measures need to be taken, such as refilling or scrapping.

Product Advantages

1. Relatively easy to operate: Compared to fully automatic filling machines, semi-automatic filling machines are simpler to operate and have relatively lower technical requirements for operators. After simple training, operators can get started and operate them, making them suitable for small and medium-sized enterprises or relatively small-scale production scenarios.

2. High flexibility: It can be adjusted and adapted to different gas types, packaging containers, and filling requirements to meet the filling needs of various gas products. For example, it can be used for filling flammable gases such as butane, inert gases such as nitrogen, and some special-purpose gases.

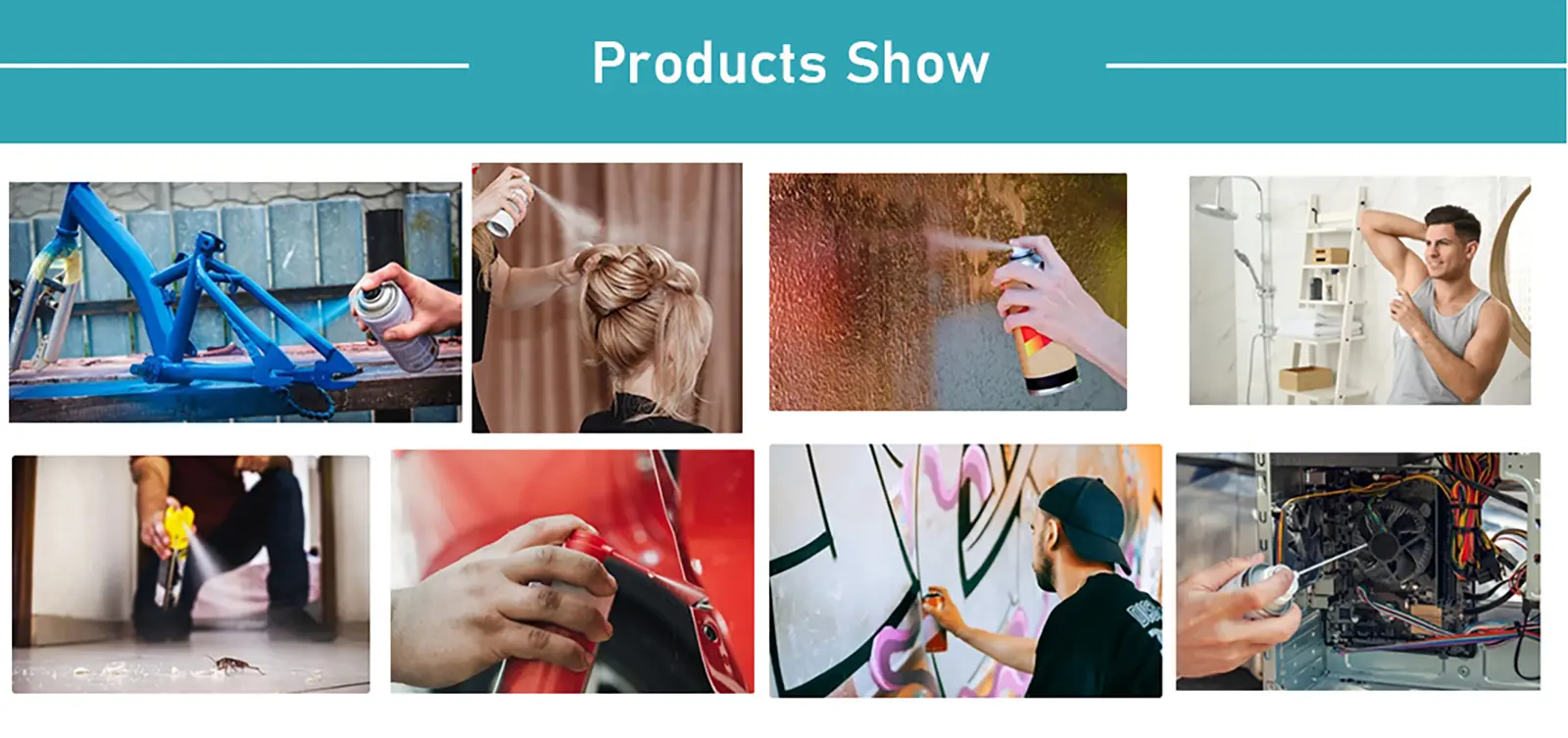

PRODUCT Applications