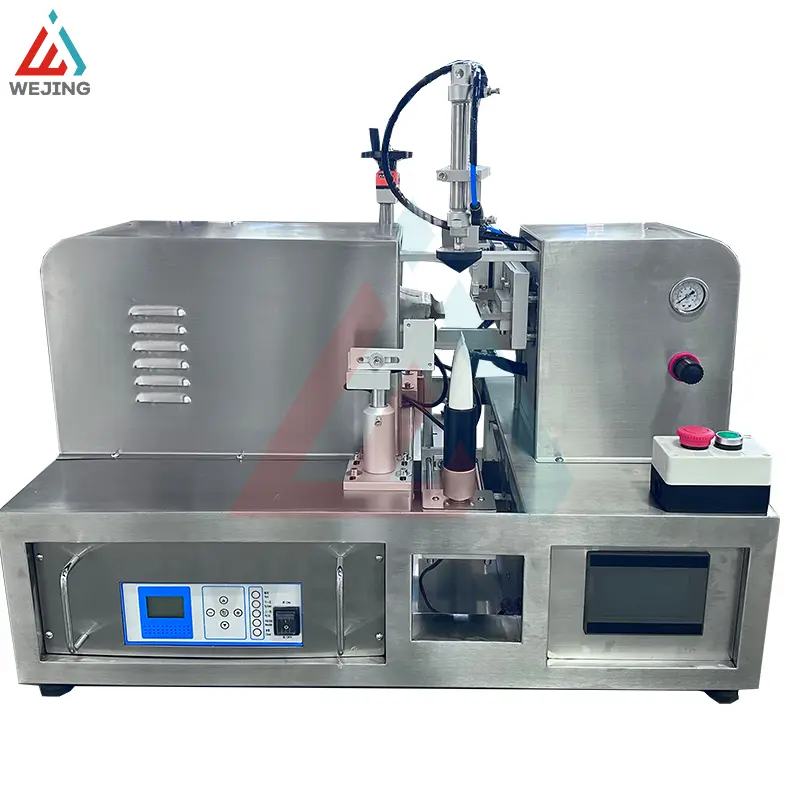

Semi Automatic Ultrasonic Hose Sealing Machine

Tube Filling Sealing MachinePRODUCT PARAMETERS

|

Power Supply |

220V50Hz |

|

Pressure |

0.5Mpa |

|

Sealing efficiency |

8-12 pieces/minute |

|

Sealing height |

50-220mm (height can be customized) |

|

Frequency |

20KHz |

|

Power |

2KW |

|

Sealing diameter |

15-50mm (customizable width) |

|

Machine weight |

200KG |

|

Material Science |

1880 * 680 * 1550mm, 304 stainless steel |

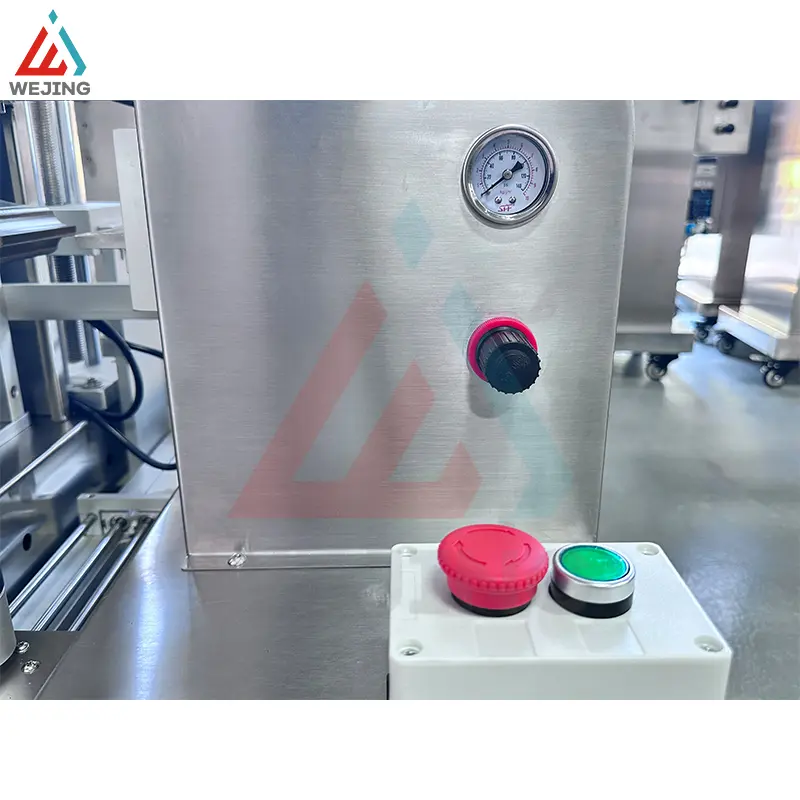

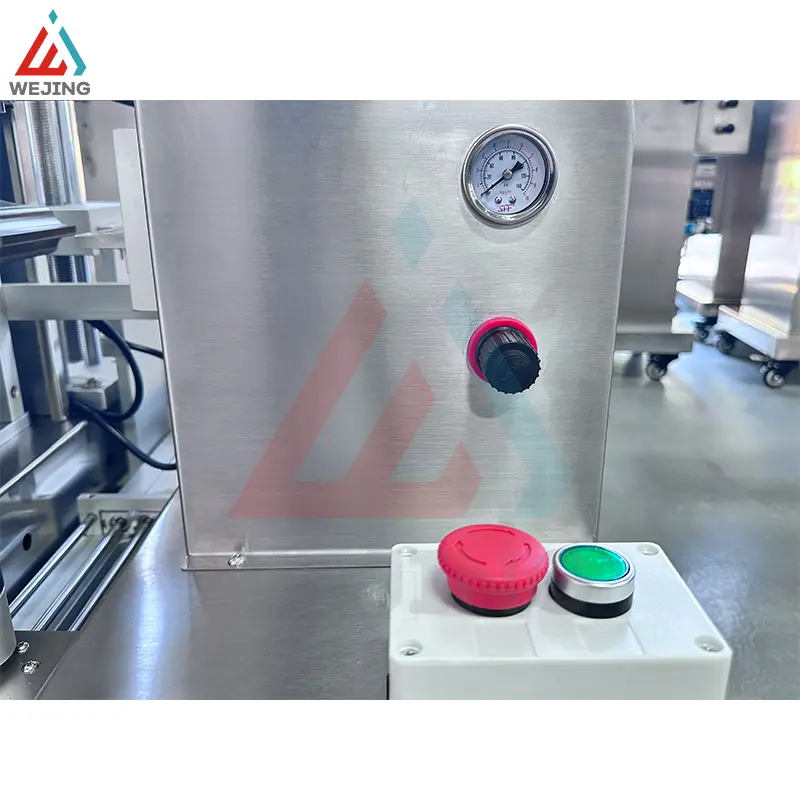

1. Small footprint, economical control panel, and easy operation.

2. The product is easy to replace, and only one type of mold can be replaced

2. The product is easy to replace, and only one type of mold can be replaced

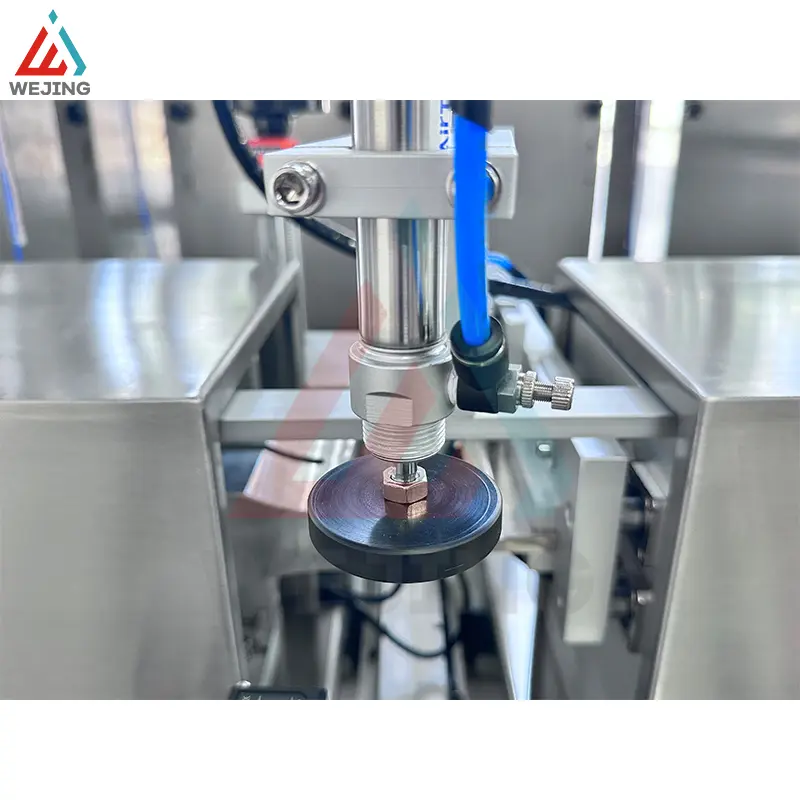

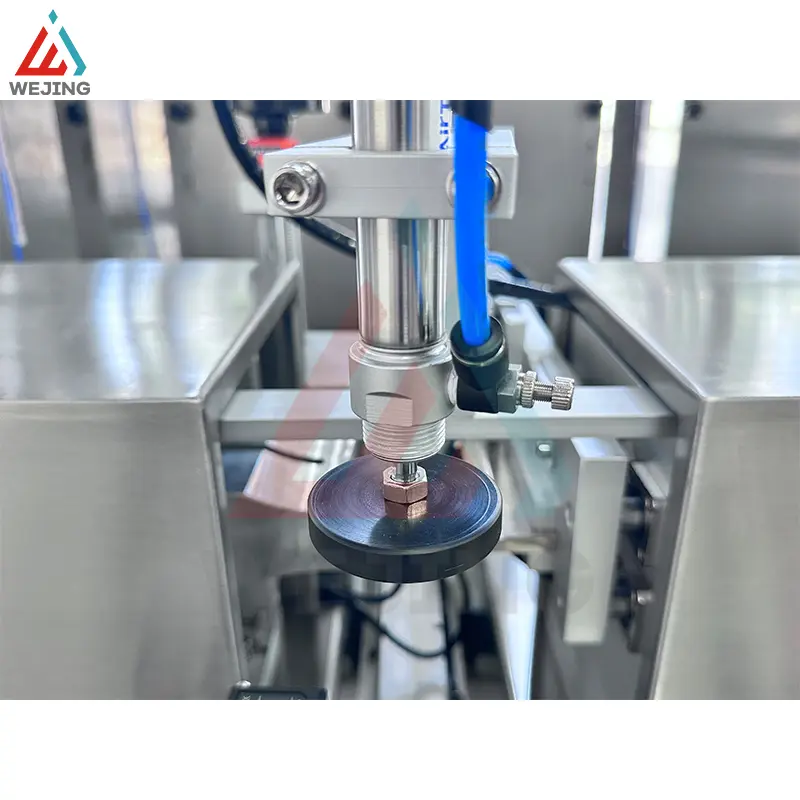

3. Automatic calibration, ultrasonic sealing, beautiful sealing.

4. Equipped with safety device, no induction, no sealing, overload protection

4. Equipped with safety device, no induction, no sealing, overload protection

5. Famous brand electric parts are durable and not easy to break.

6. Additional loading.

6. Additional loading.

Working Principle

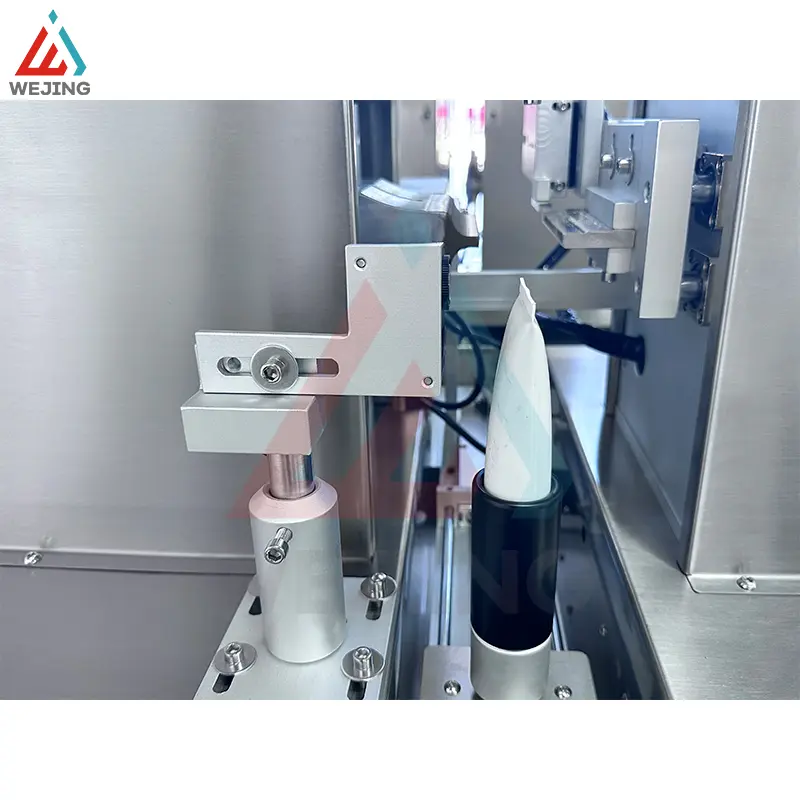

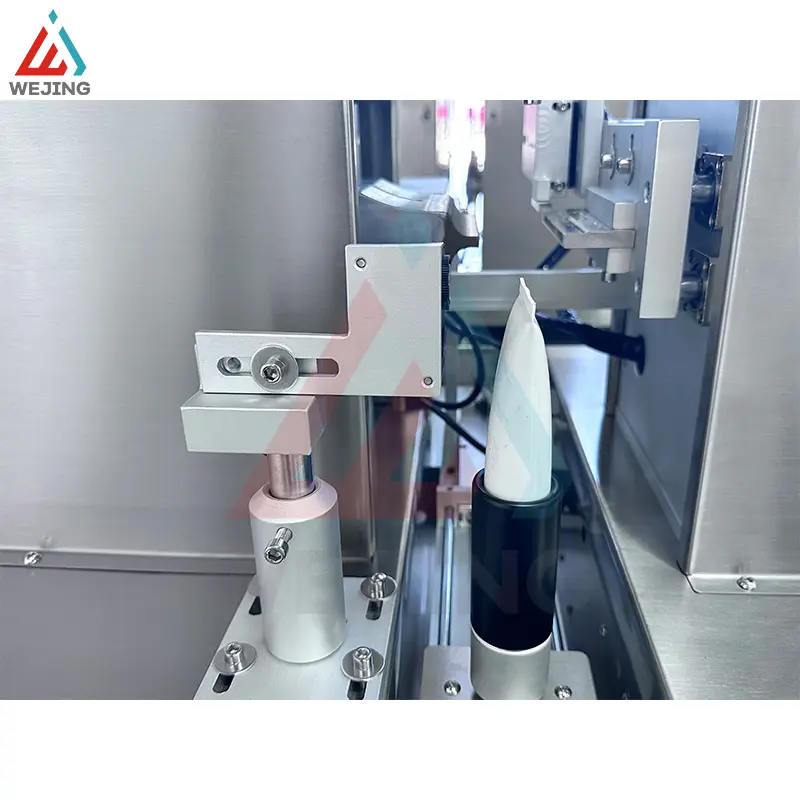

1. The tail hose should be installed in a specific working position. After the machine is started, the hose is transported to the seal by the conveyor.

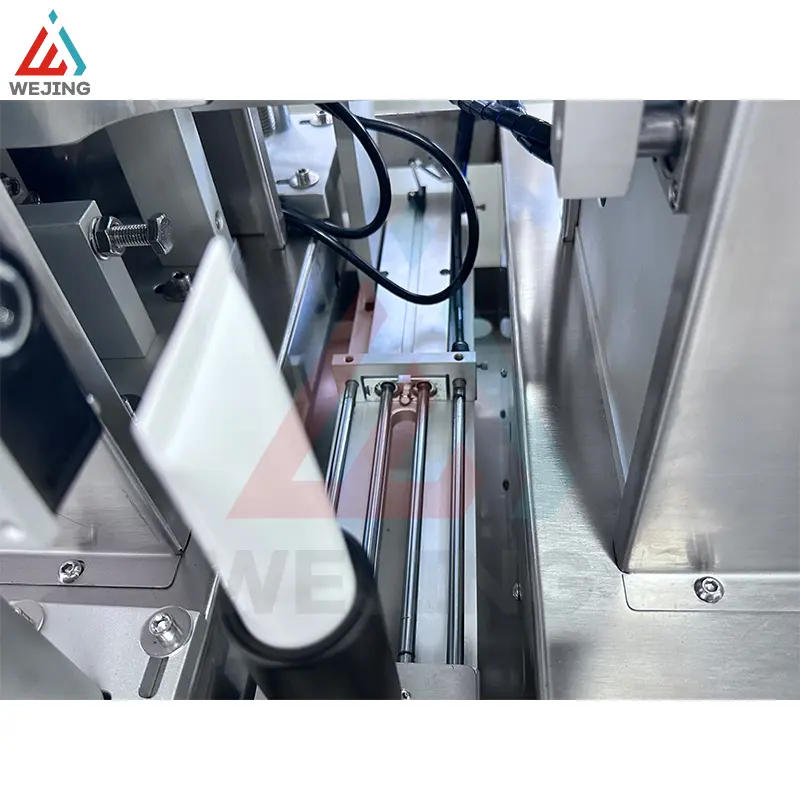

2. The heating system starts working, usually softening the material inside the sealed area through electric heating or hot air heating. At the same time, the mechanical compression device compresses the hose, forming a certain tail shape.

3. Under the combined action of heating and extrusion, melt the material at the end of the hose together to achieve sealing. Then the cooling system quickly cools the sealed part at the rear, making the seal more durable.

4. During the entire process, the operator needs to manually place the hose and start the machine, and perform some auxiliary operations as needed, such as adjusting the position of the hose.

2. The heating system starts working, usually softening the material inside the sealed area through electric heating or hot air heating. At the same time, the mechanical compression device compresses the hose, forming a certain tail shape.

3. Under the combined action of heating and extrusion, melt the material at the end of the hose together to achieve sealing. Then the cooling system quickly cools the sealed part at the rear, making the seal more durable.

4. During the entire process, the operator needs to manually place the hose and start the machine, and perform some auxiliary operations as needed, such as adjusting the position of the hose.

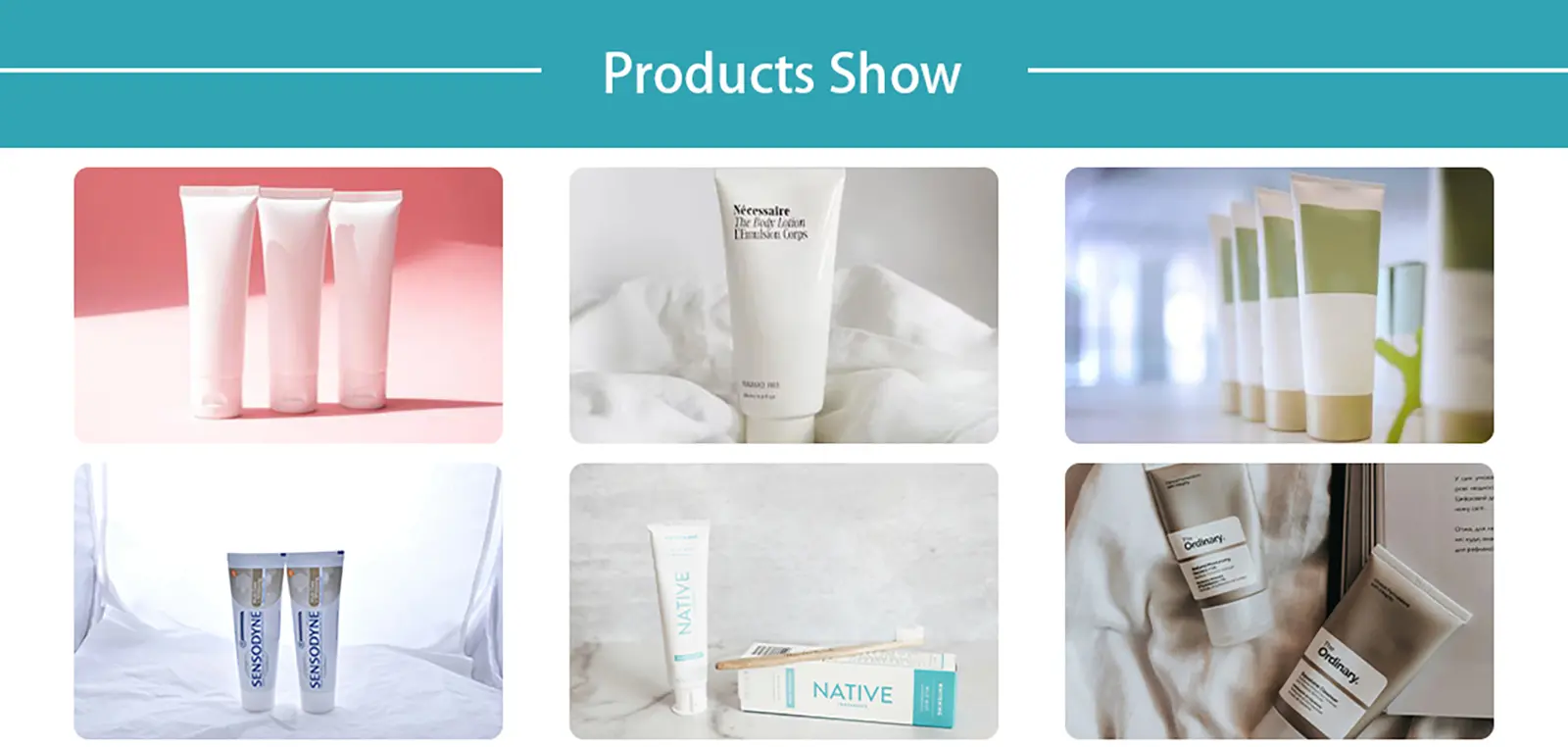

Product Applications

1. In the cosmetics industry, it can provide reliable sealing for toothpaste tubes, face washing milk tubes, etc.Ensure the beauty and hygiene of the product.

2. In the pharmaceutical industry, it can be sealed with ointments, eye drops, etc. To ensure the sealing and safety of the medication.

3. In the food industry, we can seal tubes used for sauces, honey, etc. Extend the shelf life of the product.

4. The chemical industry can also handle chemical reagent hoses, etc. Prevent leakage and contamination.

2. In the pharmaceutical industry, it can be sealed with ointments, eye drops, etc. To ensure the sealing and safety of the medication.

3. In the food industry, we can seal tubes used for sauces, honey, etc. Extend the shelf life of the product.

4. The chemical industry can also handle chemical reagent hoses, etc. Prevent leakage and contamination.