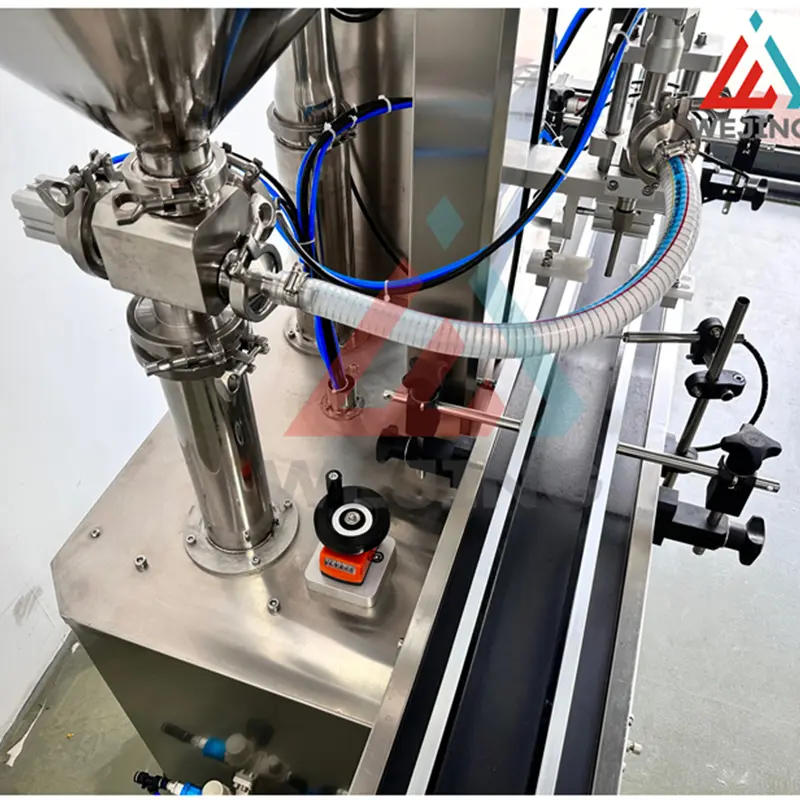

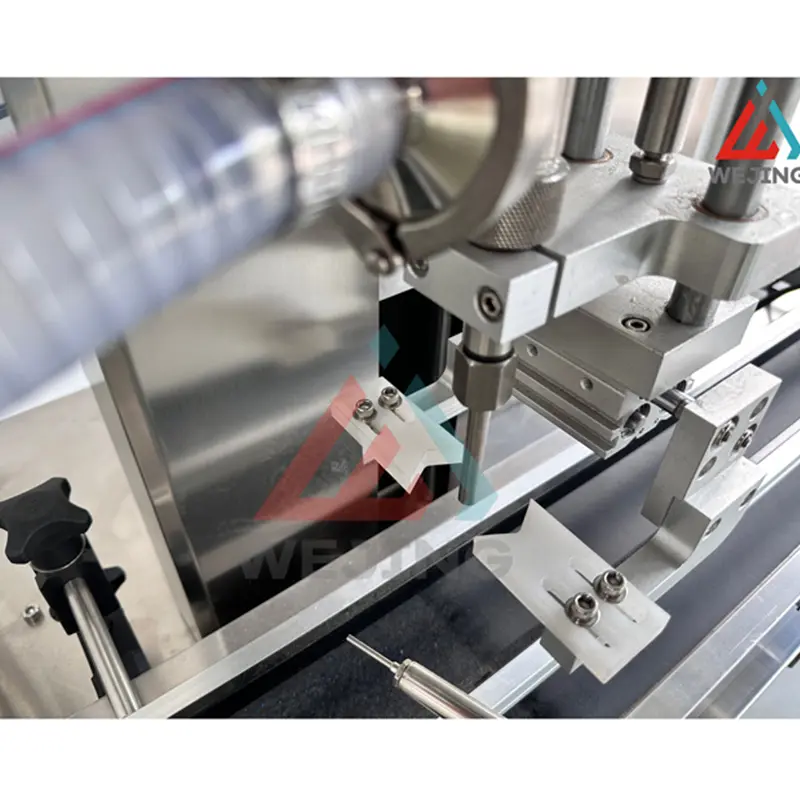

Single Head High-speed Filling Machine

Cosmetic Filling MachinePRODUCT PARAMETERS

|

Material Science |

SS304/SS316 |

|

Capacity |

30-35 bottles/minute (500ml) |

|

Filling pump |

Gear pump * 1 |

|

Pump motor |

Servo motor |

|

Filling accuracy |

±1% |

|

Filling amount |

20-5000ml (performance can be configured according to requirements) |

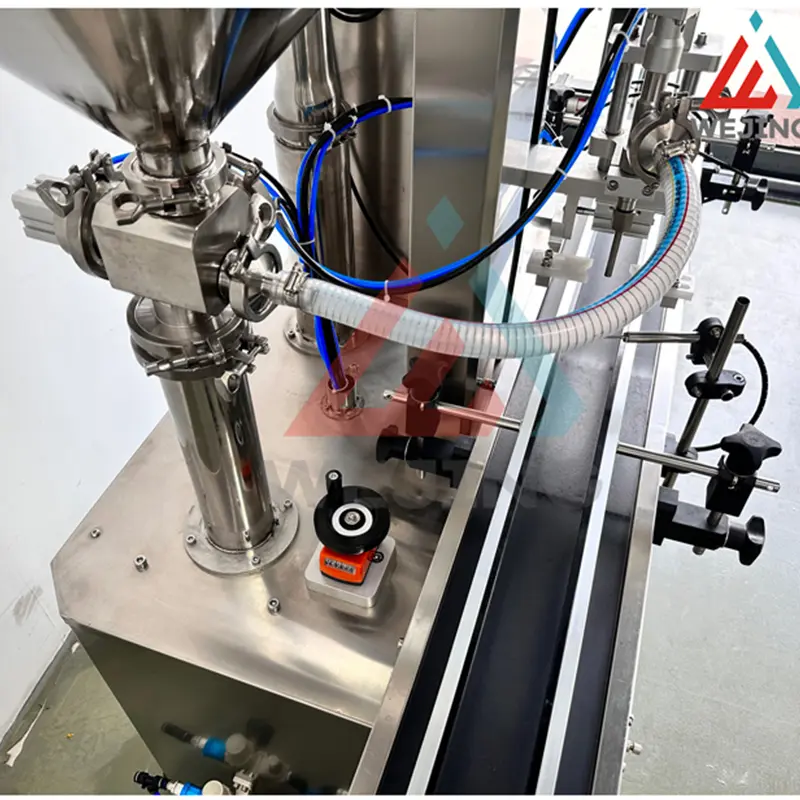

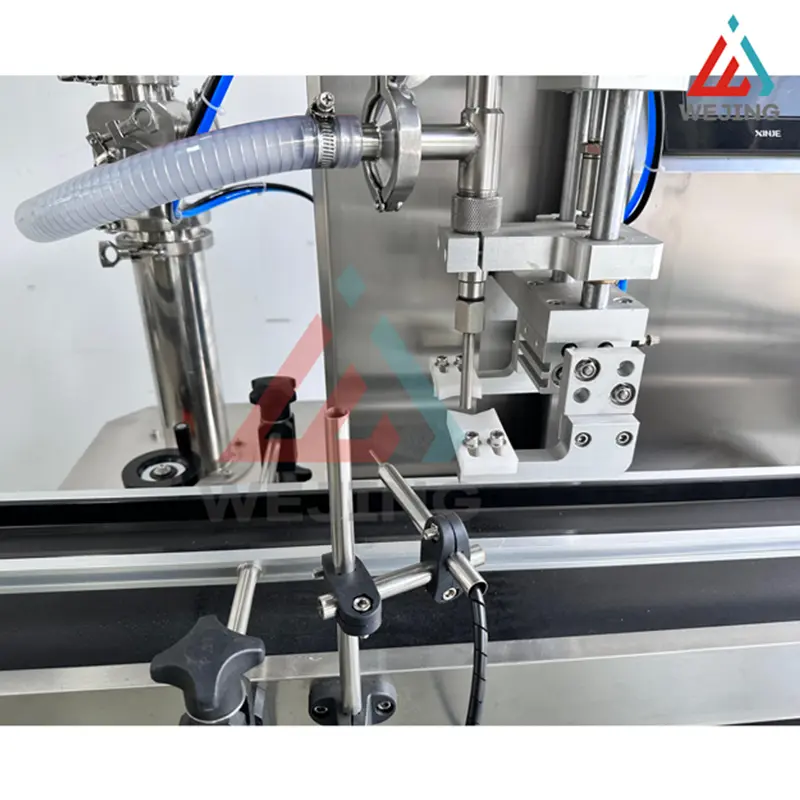

1. The framework is composed of SUS # 304 and advanced anodized aluminum alloy, and the contact part of material SUS # 316 (with foot cup * 4)

2. Loading range: 20ml-5000 ml (company independently developed gear pump 60l/min flow rate 316 head pump)

2. Loading range: 20ml-5000 ml (company independently developed gear pump 60l/min flow rate 316 head pump)

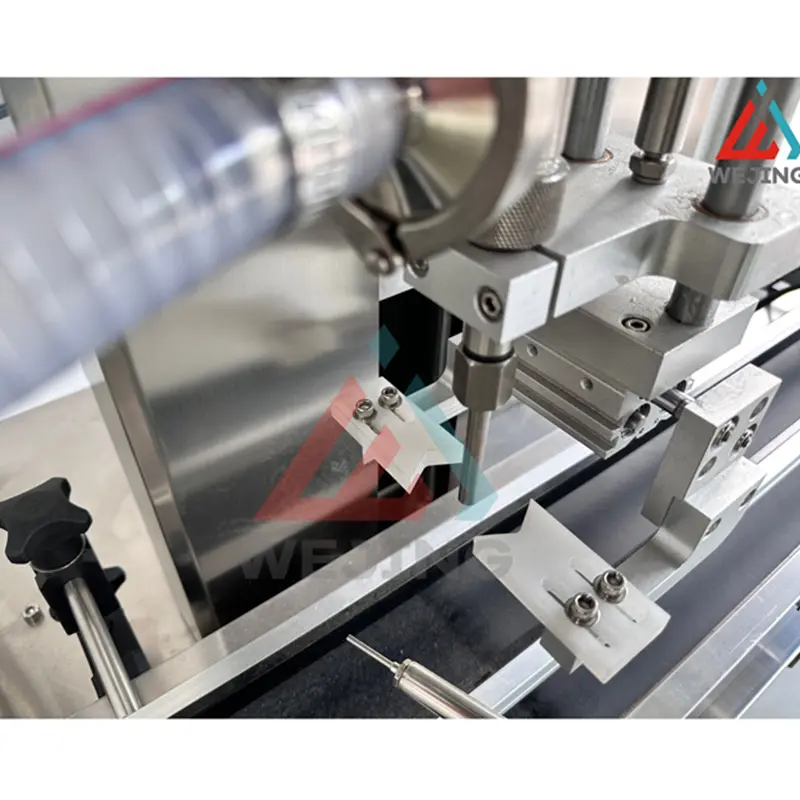

3. The packing is started by a servo motor. Two speeds can be set, and the desired filling amount can be directly touched for easy operation. The filling head is lifted by a servo motor.

4. Enhance the anti drip filling head (brushed products can be equipped with brushed filling heads)

4. Enhance the anti drip filling head (brushed products can be equipped with brushed filling heads)

5. Easy to operate, no need for professional training.

6. Easy to clean, some equipment can be cleaned without disassembling parts

6. Easy to clean, some equipment can be cleaned without disassembling parts

Product Applications

The filling machine has high compatibility and can fill various viscous materials such as water, cream, batter, cream, milk, cream, ointment, essential oil, washing powder, shampoo, shower gel, semi liquid substances, honey, etc.

Quality Control

1. Raw materials are selected from high-quality components.

2. Production adopts strict technical standards, and each process undergoes rigorous inspection.

3. Conduct comprehensive performance testing before delivery to ensure quality.

4. Provide technical support and usage service guidance to help customers maintain equipment correctly, extend equipment life, maintain good operating conditions, strictly control quality from all directions, and provide customers with reliable filling equipment.

2. Production adopts strict technical standards, and each process undergoes rigorous inspection.

3. Conduct comprehensive performance testing before delivery to ensure quality.

4. Provide technical support and usage service guidance to help customers maintain equipment correctly, extend equipment life, maintain good operating conditions, strictly control quality from all directions, and provide customers with reliable filling equipment.

After-sale Service

1. Installation, debugging, and job training.

2. Annual warranty and spare parts supply.

3. Regular maintenance, troubleshooting, and spare parts supply.

4. Technical transformation services.

5. Feedback mechanism after sales.

2. Annual warranty and spare parts supply.

3. Regular maintenance, troubleshooting, and spare parts supply.

4. Technical transformation services.

5. Feedback mechanism after sales.