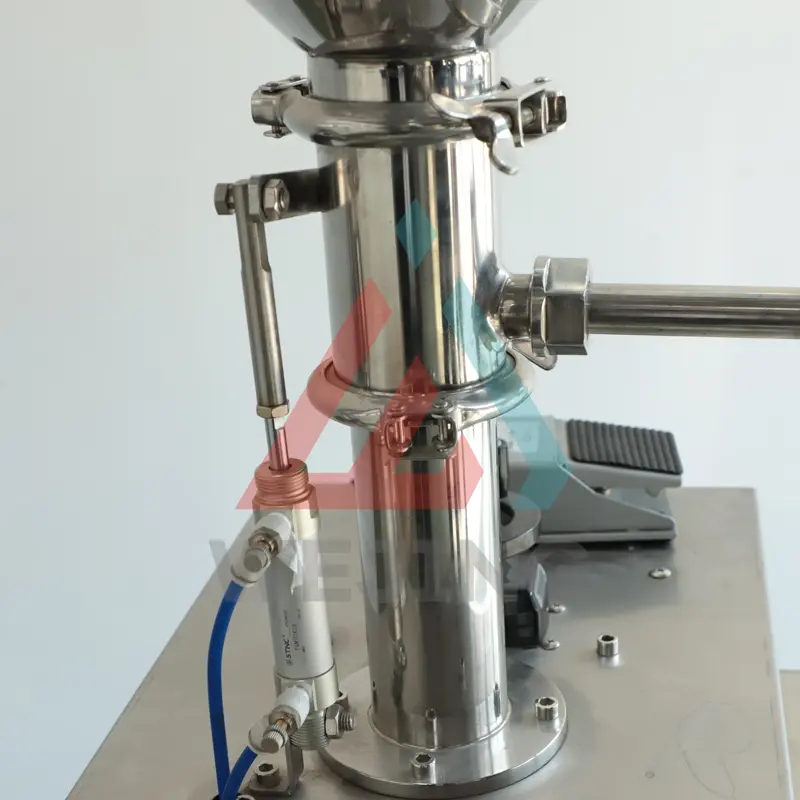

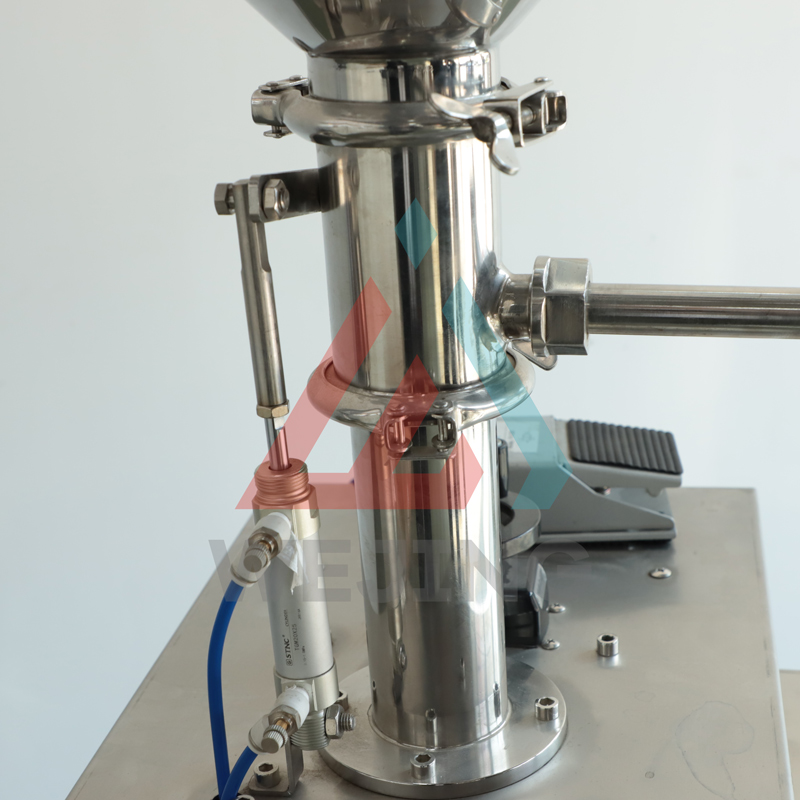

Vertical Liquid Paste Filling Machine Manual

Cosmetic Filling MachinePRODUCT PARAMETERS

|

item name |

configuration |

|

material |

304 shall be used for contact with materials and exposure |

|

Filling volume |

1-250ml |

|

Filling speed |

30-60 bottles per minute |

|

Filling accuracy |

±1% |

|

Air source pressure |

0.6-0.8Mpa |

|

Working pressure |

0.3-0.6Mpa |

|

Air consumption |

0.05 m3 / min |

|

G.W. |

About 70kg |

Dual purpose function

It can simultaneously fill both paste and liquid, with a wide range of uses to meet the filling needs of different products.

Vertical design

compact structure, small area, easy installation, limited space.

Easy to operate

The work does not require professional technical personnel, and ordinary employees can start working after simple training, reducing labor costs.

Stable operation

Market testing, reliable operation, reducing production interruptions caused by equipment failures, and improving production efficiency.

Product Applications

The fully automatic filling and sealing machine is an efficient packaging equipment. It combines filling and sealing functions on one machine, which can automatically complete various flexible tube packaging operations. This device adopts advanced technology to ensure filling accuracy, and the tail seal is durable and beautiful. Widely used in industries such as cosmetics, pharmaceuticals, and food, it has improved production efficiency, reduced labor costs, and brought huge economic benefits to enterprises.

Quality Control

1. High - quality components are chosen as the raw materials.

2. Strict technical standards are adopted in production, and each procedure is subject to strict inspection.

3. Comprehensive performance tests are carried out before delivery to guarantee the quality.

4. Technical support and usage service guidance are provided to assist customers in maintaining the equipment correctly, prolonging the equipment's lifespan, keeping it in good operating condition. Quality is strictly controlled from all aspects to supply customers with reliable filling equipment.

2. Strict technical standards are adopted in production, and each procedure is subject to strict inspection.

3. Comprehensive performance tests are carried out before delivery to guarantee the quality.

4. Technical support and usage service guidance are provided to assist customers in maintaining the equipment correctly, prolonging the equipment's lifespan, keeping it in good operating condition. Quality is strictly controlled from all aspects to supply customers with reliable filling equipment.