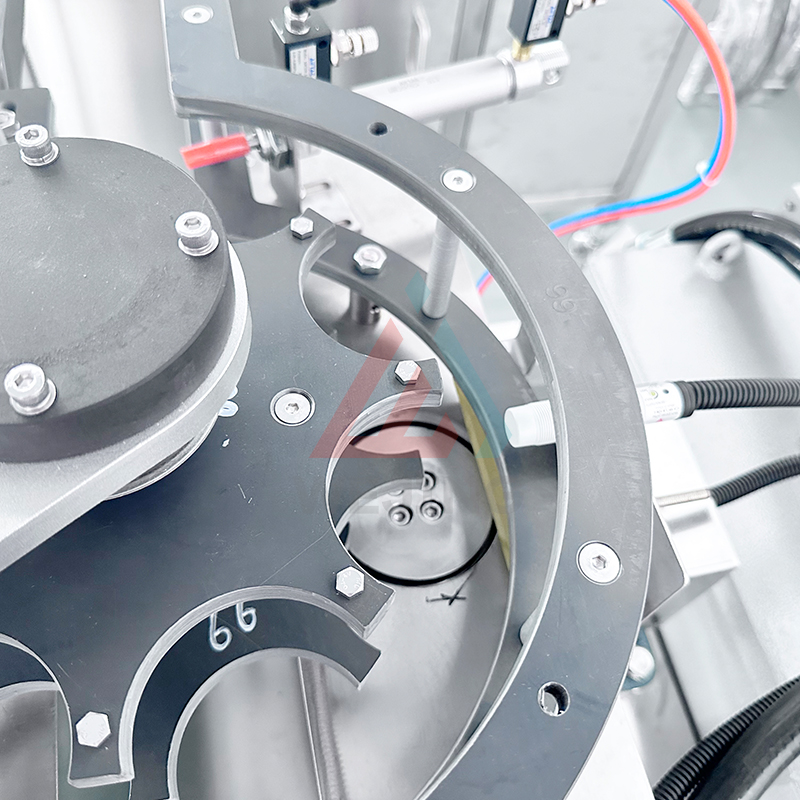

Weight Checking Machine for Aerosol Line

1. Pinpoint Accuracy: The Electronic Weight Checking Machine is engineered to provide highly accurate measurements, ensuring every aerosol product is filled uniformly and upholds the most stringent quality criteria.2. Efficient and Intuitive: Its user-centric design features a simple yet effective interface and controls, making the weighing process effortless. This not only cuts down on idle time but also maximizes production throughput.3. Rapid Cstomization: Capable of swift reconfiguration, the machine can adapt to a wide array of product specs in no time, adding significant flexibility to any production setup.4. Robust and Trustworthy: Built in line with industry best practices, our machine guarantees long-term, reliable service. It's constructed to withstand the rigors of continuous use, reducing the need for frequent maintenance and associated costs.

Automatic Aerosol Filling MachinePRODUCT PARAMETERS

|

Allowance |

≤±1g |

|

Max. weight |

0-1500g |

|

Capacity |

60-70cans/min |

|

Working pressure |

0.5MPa |

|

Suitable can diameter |

35-73mm |

|

Suitable can height |

90-330mm |

|

Power |

AC220V/50HZ |

Product Applications

1. Accurate Weighing & Filling: Meticulously weighs and fills aerosol products, guaranteeing that each dose dispensed is spot-on accurate, leaving no room for variance.

2. Steadfast Quality Guardianship: Plays a pivotal role in upholding a uniform product weight and uncompromised quality throughout the production run, acting as a reliable sentinel.

3. Smart Production Surveillance: Expedite the process of rapid adjustments and calibrations to accommodate various product specifications.

4. Swift Adaptation & Fine-Tuning: Enables hassle-free and rapid modifications and calibrations, allowing the machine to nimbly adapt to the specific demands of diverse product specs.

2. Steadfast Quality Guardianship: Plays a pivotal role in upholding a uniform product weight and uncompromised quality throughout the production run, acting as a reliable sentinel.

3. Smart Production Surveillance: Expedite the process of rapid adjustments and calibrations to accommodate various product specifications.

4. Swift Adaptation & Fine-Tuning: Enables hassle-free and rapid modifications and calibrations, allowing the machine to nimbly adapt to the specific demands of diverse product specs.

5. Regulatory Adherence:Stays firmly in line with all relevant weight regulations and standards, giving manufacturers the peace of mind that their operations are fully compliant.

Product operate guide

1. Initiation & Activation:

2. Precision Tuning:

3. Customized Configuration:

4. Automated Weigh & Fill Process:

5. Upkeep & Hygiene Routine:

Flip the power switch to bring the machine to life and patiently await its full start-up sequence as it readies itself for operation.

Employ standard weights to fine-tune the machine's calibration, laying the foundation for highly accurate measurement outcomes throughout its use.

Navigate through the options to handpick the most suitable product settings and parameters that align with the specific aerosol item you're handling.

Gently position the aerosol product onto the weighing surface, and watch as the machine springs into action, autonomously weighing and filling with precision and speed.

Incorporate regular cleaning and maintenance sessions into your schedule to keep the machine in prime condition, guaranteeing its reliable and seamless operation day in and day out.