Choosing the right Liquid Filling Machine is crucial for your business. In 2026, various options can meet diverse needs. From small startups to large corporations, these machines play a vital role in production efficiency.

Consider the specific requirements of your operation. Do you need speed, precision, or versatility? Each Liquid Filling Machine has unique features. Some excel in high-volume production. Others offer flexibility for different container sizes.

It's important to reflect on your goals. Are you prioritizing cost, technology, or ease of use? Making a decision can be daunting. The perfect machine should align with your business vision. A hasty choice may lead to operational challenges later.

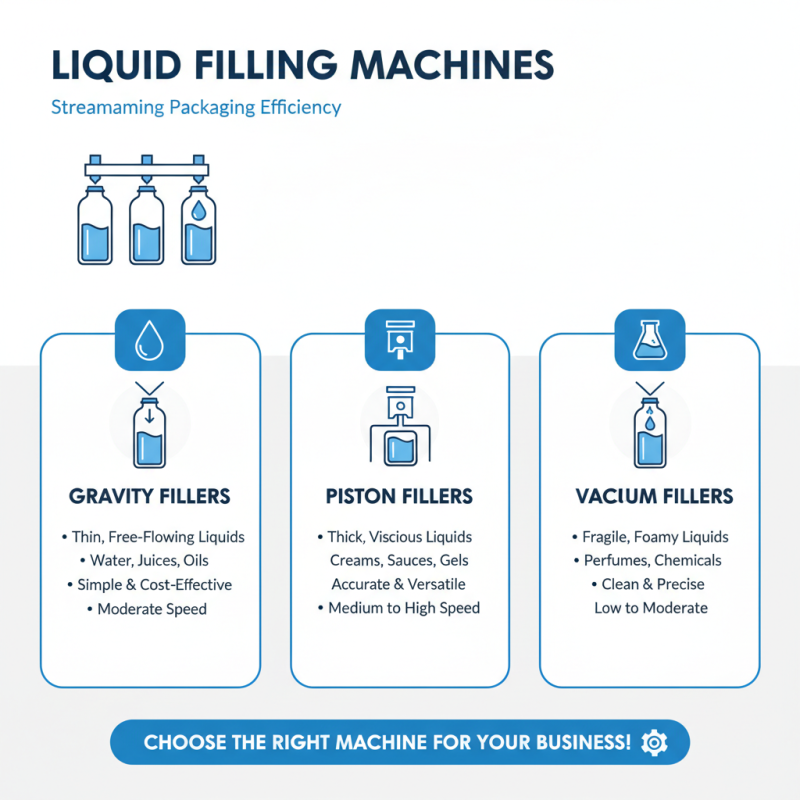

Liquid filling machines are crucial for many businesses. They help streamline the packaging process and improve efficiency. Understanding the different types of these machines is essential before making a decision. There are several types, including gravity fillers, piston fillers, and vacuum fillers. Each has its strengths and weaknesses, depending on the liquid's viscosity and the desired speed of production.

According to industry reports, around 40% of companies still rely on manual filling processes. This can lead to inconsistencies and inefficiencies. Investing in a liquid filling machine can significantly decrease labor costs and improve accuracy. For instance, piston fillers are ideal for thicker liquids, while gravity fillers are best for lighter fluids. Not every machine suits every business. Operational needs should dictate your choice.

Features such as speed, accuracy, and integration with existing systems are vital. Many machines offer advanced options like digital controls and automated changeovers. However, not all businesses need these high-tech features. Sometimes, simpler machines can provide adequate performance without the complexity. Each decision requires careful consideration of your operational realities and growth plans.

Choosing the right liquid filling machine for your business is vital. There are several key considerations that can impact the efficiency of your production line. For instance, the type of liquid being filled can determine the technology needed. Viscosity matters. A study by the Packaging Machinery Manufacturers Institute (PMMI) revealed that temperamental liquids often require specialized systems to avoid spillage.

Speed is another important factor. In a competitive market, maximizing output is essential. According to a recent report, filling speeds of 30 to 200 containers per minute are common. Yet, many businesses underestimate the time required for changeovers and maintenance. The right machine should balance speed with reliability. It’s essential to evaluate your specific needs, as one size does not fit all.

Automation features can enhance productivity. However, not all manufacturers invest in staff training. Lack of knowledge can lead to operational hiccups. Remember, ease of use can significantly influence your decision. A machine that is difficult to operate can slow down production. Thus, while automation may reduce labor costs, ensure you have the right support and training systems in place.

When it comes to liquid filling machines, different industries have unique needs. In 2026, selecting the right machine is crucial for efficiency. Food and beverage sectors often require machines that handle thick and thin liquids. Pharmaceuticals generally need precision and hygiene. Choosing the right machine depends on the liquid viscosity and packaging type.

Tips: Assess your product’s viscosity. Thick liquids need different mechanisms than thin ones. A good fit is vital for efficient production.

Other sectors may need specialized solutions. Personal care goods often use machines that fill small containers accurately. In contrast, larger operations may prioritize speed. The market has various options, each with pros and cons. Research is essential to avoid missteps.

Tips: Consider your production volume. A high-speed machine might seem appealing but can lead to waste. Balance speed with accuracy for optimal results.

The liquid filling machine market is rapidly evolving. In 2026, businesses face many options. A comparative analysis of leading brands reveals notable differences. According to industry reports, the global liquid filling machine market size is expected to reach $4.2 billion by 2025. These data show high growth potential.

Companies often seek machines based on precision and speed. Some models offer filling speeds up to 120 bottles per minute. Yet, accuracy varies. Some machines boast an error rate of less than 0.5%, while others struggle with discrepancies. This inconsistency can impact production rates.

Additionally, maintenance costs vary significantly among models. Regular upkeep is essential for optimal performance. Businesses should assess long-term expenses, not just the initial investment. A machine may have a lower purchase price but lead to higher operational costs. This aspect deserves careful thought. Ultimately, exploring the landscape of liquid filling machines involves balancing speed, accuracy, and overall value.

Liquid filling machines are vital for many businesses. Proper maintenance ensures they run efficiently and have a long lifespan. Regularly inspecting these machines can prevent unexpected breakdowns. A simple visual check can reveal issues like leaks or wear. Pay attention to the seals and hoses, as they often wear out first.

Cleaning is another critical aspect of maintenance. Residues can build up and affect performance. Using appropriate cleaning agents helps maintain functionality. It’s essential to follow cleaning procedures as per the manufacturer's guidelines. Neglecting cleaning can lead to costly repairs and downtime.

Monitoring performance consistently will help you catch small problems early. Not all businesses have the resources for constant oversight. However, even a brief daily check can make a difference. Recording any irregularities provides valuable data for future maintenance. Addressing issues promptly not only enhances machine life but also ensures product quality.

| Machine Type | Filling Capacity (Bottles/Min) | Industry Use | Maintenance Frequency | Estimated Cost (USD) |

|---|---|---|---|---|

| Semi-Automatic Filling Machine | 20-30 | Food & Beverage | Monthly | $5,000 - $10,000 |

| Fully Automatic Filling Machine | 60-120 | Pharmaceutical | Weekly | $20,000 - $50,000 |

| Piston Filling Machine | 30-45 | Cosmetics | Monthly | $10,000 - $15,000 |

| Continuous Filling Machine | 100-200 | Chemical | Biweekly | $30,000 - $70,000 |

| Gravity Fillers | 15-25 | Beverages | Monthly | $4,000 - $8,000 |