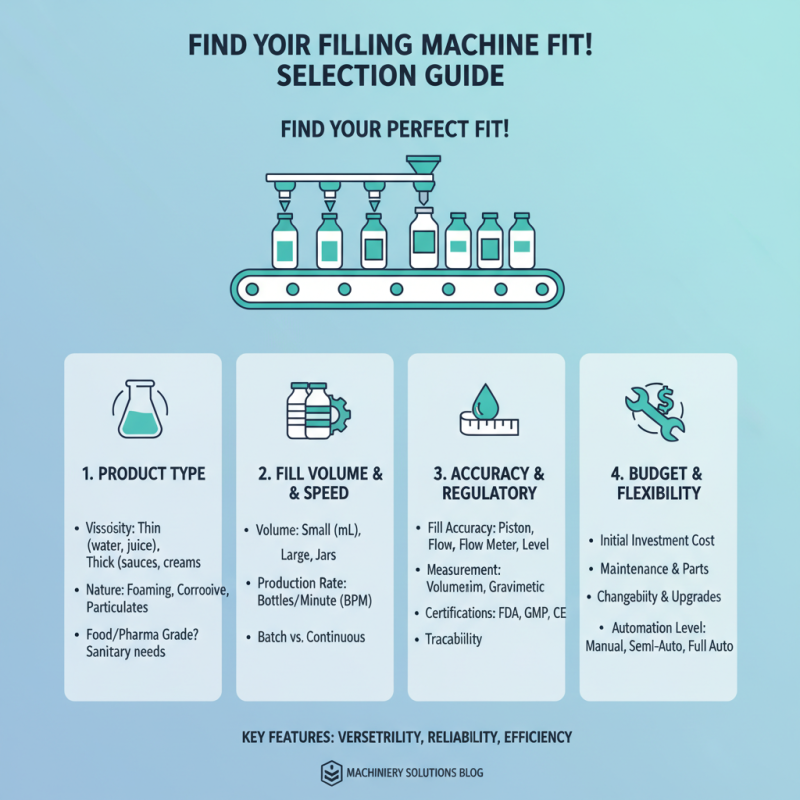

When selecting the right Liquid Filling Machines for your business, several factors come into play. The machine's efficiency impacts productivity directly. Choosing the wrong model can lead to downtime and increased costs. Businesses should assess their product types and viscosity levels. Not all machines suit every liquid. For example, thick liquids require specialized equipment.

Additionally, consider the volume output. Machines vary widely in production capacity. A small operation might not need a high-speed model. Choosing an overly complex machine can create challenges. Maintenance and training are equally important. Employees must be comfortable operating the equipment.

Reflect on your long-term needs as well. As your business grows, can the machine adapt? Will it handle future products efficiently? These questions are vital when investing. Remember, the right Liquid Filling Machines can streamline operations, but the wrong choice may lead to regrettable setbacks.

When selecting the right liquid filling machine, understanding the available types is crucial. The market offers several categories, such as gravity fillers, pressure fillers, and vacuum fillers. Gravity fillers are often used for thin liquids. They are simple and economical. However, they may struggle with thicker products. Pressure fillers, on the other hand, work best for viscous liquids. According to industry reports, around 25% of manufacturers prefer this type for its accuracy.

Vacuum fillers are another option worth considering. They efficiently fill containers without introducing air. This process helps maintain product integrity. Research indicates that around 40% of production operations face challenges with air bubbles. Choosing a vacuum filler can mitigate this issue. However, these machines can be more complex and costly.

Each type has its pros and cons. It's important to analyze your product needs. Will you be filling a variety of liquid types or just one? The right machine can streamline your operations, but making a wrong choice may lead to inefficiencies. Always consult with industry experts and assess your specific requirements before making a decision.

Choosing the right liquid filling machine is crucial for a business. Different industries have unique requirements. A few key features make the selection process straightforward.

The fill rate is essential. Machines can fill at speeds ranging from 30 to 300 bottles per minute. This influences both efficiency and productivity. Businesses should analyze their production volume. Inadequate speed can lead to bottlenecks.

Accuracy is another critical factor. Filling machines typically achieve an accuracy rate of 0.5% to 1%. A small error can lead to significant losses over time. The compatibility with various container sizes is vital too. Machines should handle a range from small vials to large drums. Flexibility opens up market opportunities.

Maintenance requirements can often be overlooked. Machines that require frequent repairs can disrupt production schedules. It's essential to consider ease of cleaning, especially in the food and beverage sector. Regular breakdowns create unexpected costs. Finding a balance between initial price and long-term operation is crucial. Consider all these factors to make a well-rounded choice.

When evaluating liquid filling machines, production needs and budgets are key. Businesses should carefully assess their requirements. This includes the types of liquids, container sizes, and production rates. Not all machines fit every need. Some industries may require more precise filling, while others focus on speed.

Tips: Start by analyzing your production volume. If your output is high, a machine with faster speeds may be necessary. For smaller businesses, a more straightforward solution could be a better investment. Flexibility is essential.

Budget constraints greatly affect options. High-quality machines can be expensive but may lead to savings in the long run. Consider total costs: maintenance, operation, and efficiency. Cutting corners on initial investment can lead to increased downtime. This impacts profits and can be frustrating.

Tips: Always include maintenance costs in your budget. Research common issues and their solutions. Make informed decisions. Engaging with manufacturers for demonstrations can clarify doubts. Sometimes, seeing the machine in action reveals strengths and weaknesses.

When selecting liquid filling machines, quality and reliability are crucial. It's essential to evaluate suppliers carefully. Many manufacturers claim to offer high-quality products, but not all live up to their promises. Start by assessing their experience in the industry. A company with years of expertise often has a better understanding of specific needs.

Look for customer reviews and ratings. Engaging with current users of their machines can provide valuable insights. Positive feedback can indicate reliability. However, don't ignore negative comments, as they reveal potential issues. Communication with the supplier matters too. A responsive team reflects their commitment to customer satisfaction.

Visiting potential suppliers can be beneficial. Observing their production process helps gauge their quality standards. Consider their after-sales support. Machines require maintenance, and reliable suppliers will offer assistance when needed. Remember, choosing a machine is an investment. Take the time to reflect on all factors involved.

Maintaining liquid filling equipment is crucial for efficiency.

Regular cleaning is essential. Accumulation of residues can lead to contamination. Create a schedule for daily and weekly cleanings. This keeps your equipment in tip-top shape.

Optimizing your filling equipment is also vital. Check for any leaks regularly. Leaks can waste liquid and lead to costly downtime. Inspect every component. This includes nozzles and hoses. Replace any worn parts immediately.

Training your staff is just as important. They should know the equipment well. Mistakes happen, even with the best machines. Encourage feedback from operators. They may notice issues you overlook. An open line of communication can help improve operations. Regular assessments can pinpoint inefficiencies. Making small adjustments can lead to big results.