0102030405

Comparing BOV and Traditional Aerosol Filling Machines: Making the Right Choice for Your Business

2025-02-15

Introduction

In the ever - evolving landscape of aerosol packaging, manufacturers are constantly on the lookout for technologies that can enhance efficiency, product safety, sustainability, and the overall consumer experience. Among the various advancements, Bag on Valve (BOV) aerosol filling machines and traditional aerosol filling machines stand out as two leading solutions. Although both are designed to fill products into aerosol cans, they have distinct characteristics that can greatly impact business decisions.

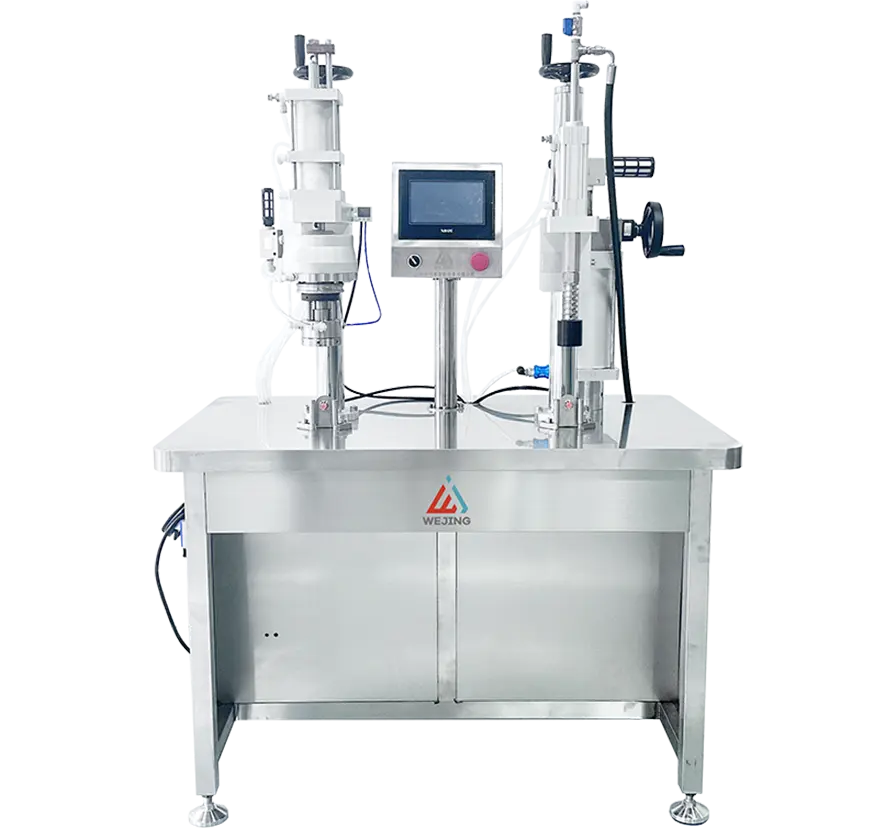

Understanding BOV Aerosol Filling Machines

A BOV aerosol filling machine is a sophisticated packaging system that operates differently from traditional counterparts. Instead of using pressurized gas directly inside the aerosol can, it incorporates a bag or pouch within the can. The product is placed inside this bag, and a valve is attached to it. When the product needs to be dispensed, the bag collapses under external pressure, allowing the product to be released. The propellant gas, which is used to push the product out, is stored outside the can. This design helps in maintaining the quality and integrity of the product by preventing direct contact between the gas and the product.

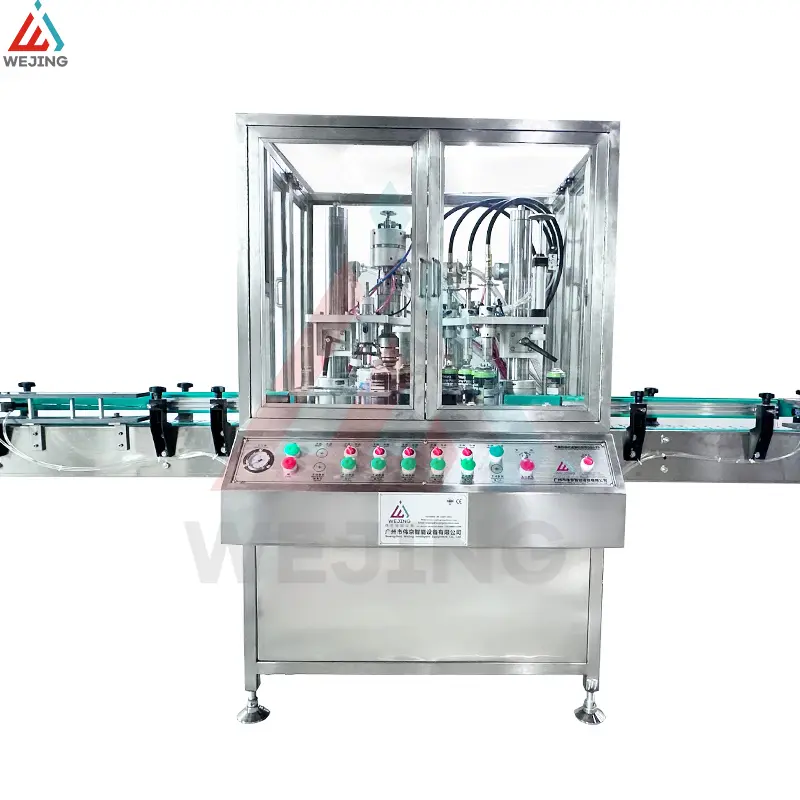

How Traditional Aerosol Filling Machines Operate

Traditional aerosol filling machines, conversely, rely on pressurized gases like butane or propane, which are introduced directly into the can during the filling process. The gas and the product are mixed together, and then the can is sealed with a valve. When the valve is activated, the pressure from the gas forces the product out of the can, creating an aerosol spray.

Despite their similar end - goal of product dispensing, the differences in their filling mechanisms and the materials used set them apart.

Key Distinctions between BOV and Traditional Aerosol Filling Machines

Product Quality and Safety

BOV aerosol filling machines offer a significant edge when it comes to product quality and safety. By separating the propellant from the product, they prevent the gas from coming into contact with sensitive ingredients. This separation is crucial, especially for products such as cosmetics, pharmaceuticals, and food items, as it helps in avoiding contamination and preserving the product's original composition.

In contrast, traditional aerosol filling machines mix the pressurized gas directly with the product. This can potentially change the product's formulation, particularly for sensitive products. Moreover, the use of certain traditional propellants may pose risks to the product's safety and performance.

Environmental Impact

In an era where environmental concerns are at the forefront for both consumers and manufacturers, the choice of aerosol filling technology can have a notable impact. BOV systems are considered more environmentally friendly. Since the propellant is separated from the product, BOV technology reduces the reliance on harmful chemicals like butane and propane. Some BOV systems even use compressed air or nitrogen as propellants, which have a much lower environmental impact.

Traditional aerosol filling machines, on the other hand, typically use hydrocarbon - based propellants. These propellants contribute to air pollution and global warming. Although modern formulations are more eco - friendly than their predecessors, some traditional propellants like chlorofluorocarbons (CFCs) were banned due to their severe damage to the ozone layer. Overall, BOV technology is a more sustainable option.

Shelf Life and Product Stability

BOV aerosol filling machines generally result in products with a longer shelf life and better stability. The internal bag in which the product is sealed protects it from exposure to the propellant and air. This protection helps in preventing ingredient degradation caused by oxidation or contamination. As a result, BOV - filled products can maintain their quality for extended periods.

Traditional aerosol filling machines, however, are more likely to experience product degradation. Since the propellant is mixed directly with the product, over time, the product may lose its effectiveness, and its texture and consistency may change due to exposure to air and pressurized gas.

Dispensing Control and Versatility

BOV aerosol filling machines offer greater control and versatility during the dispensing process compared to traditional ones. With the gas stored outside the can and the product dispensed through a bag, BOV systems enable more consistent and accurate dispensing. This is particularly important for products that require a specific dosage or spray pattern, such as medical sprays or cleaning solutions.

Traditional aerosol filling machines, while functional, often face challenges in maintaining a consistent spray pattern or delivery amount, especially when the can is almost empty. As the pressure inside the can decreases, the dispensing process becomes less reliable, leading to product waste and inefficiency.

Selecting the Right Aerosol Filling Machine for Your Business

The choice between a BOV aerosol filling machine and a traditional one depends on several factors related to your business needs.

Product Type and Formulation

If your business deals with high - end or sensitive products like cosmetics, pharmaceuticals, or food, a BOV system is a more suitable choice. Its ability to keep the propellant separate from the product ensures better quality, enhanced safety, and a longer shelf life.

For products that are more robust and less sensitive to degradation, such as cleaning products or air fresheners, a traditional aerosol filling machine may be adequate.

Sustainability Goals

If your company aims to reduce its environmental footprint, a BOV aerosol filling machine is the way to go. Its use of eco - friendly propellants and the separation of gas from the product align with global sustainability trends, helping your business contribute to a greener future.

Conclusion

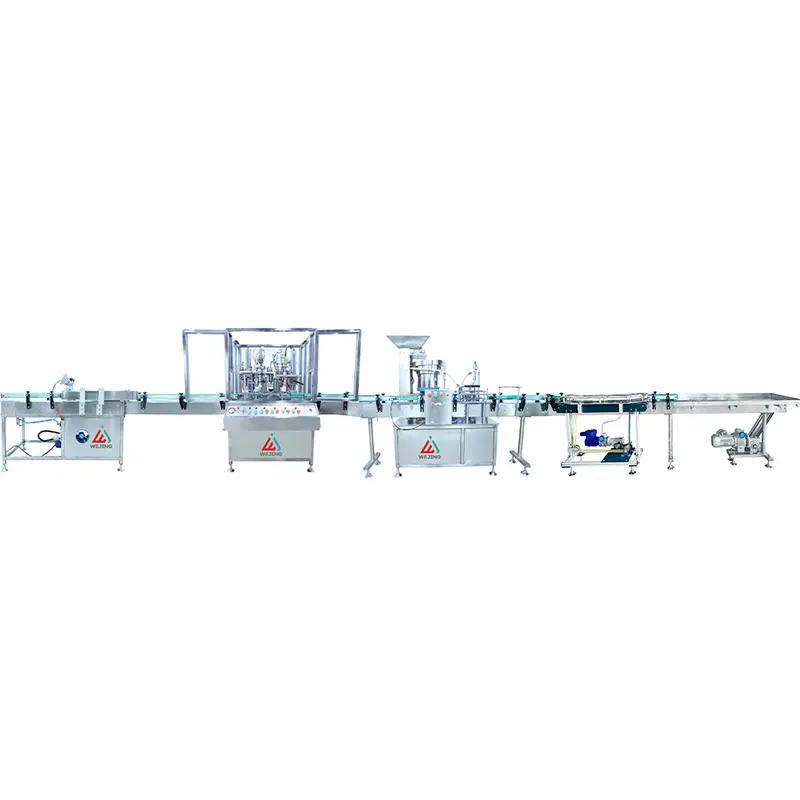

Both BOV and traditional aerosol filling machines have their own sets of pros and cons. BOV technology is particularly well - suited for businesses that prioritize product quality, safety, sustainability, and precise dispensing control. It is also an excellent choice for industries with strict requirements regarding shelf life and product integrity.

For companies looking to upgrade their aerosol filling systems, BOV technology represents the future of aerosol packaging. It offers a reliable, sustainable, and efficient solution that can help businesses stay competitive and meet the changing demands of consumers.

To explore how BOV aerosol filling machines can revolutionize your packaging process, visit [website URL] and discover how you can embrace the future of aerosol packaging.