0102030405

Homogenization vs Emulsification: Key Insights

2025-01-18

I. Emulsification: The Magic of Liquid Dispersion

In the realm of modern manufacturing and chemical processes, homogenization and emulsification are two crucial techniques that often spark curiosity. Let's first focus on emulsification. Emulsification is like a magical transformation where one liquid gets uniformly dispersed in the form of tiny droplets within another immiscible liquid. Take the classic example of oil and water. Normally, they separate into distinct layers in a container, with oil floating on top due to its lower density. However, when the right surfactants are introduced and vigorously stirred, an emulsion is born. This process has found its way into numerous products such as cosmetics, food, and medicine. It not only stabilizes the interface between oil and water but also enhances the usability and storage properties of the mixtures. Moreover, it can improve the texture and feel of the end products, making them more user-friendly.

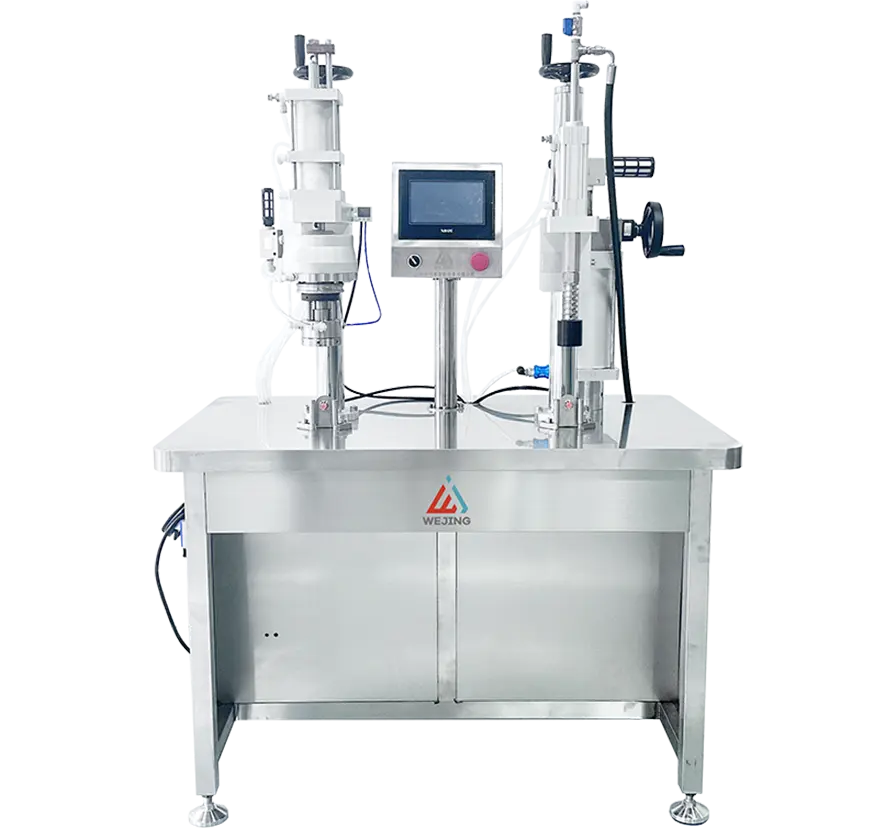

II. Key Considerations for Selecting an Emulsifier

When it comes to selecting an emulsifier, several factors come into play. One must consider the specific purpose and the materials to be emulsified. Different emulsifiers are tailored for different substances; some are designed for high-viscosity materials while others work better with low-viscosity ones. Additionally, the performance parameters of the emulsifying machine, including the structure, speed, power, and sealing performance of the emulsifying head, need to be carefully evaluated. The reliability of the emulsifier is also of utmost importance. Opting for a trusted brand or manufacturer ensures stable production and high efficiency. Maintenance and upkeep costs, along with the ease of repairing and replacing components, cannot be overlooked. Last but not least, the price of the emulsifier should fit within the budget while considering its cost-effectiveness and long-term operating costs.

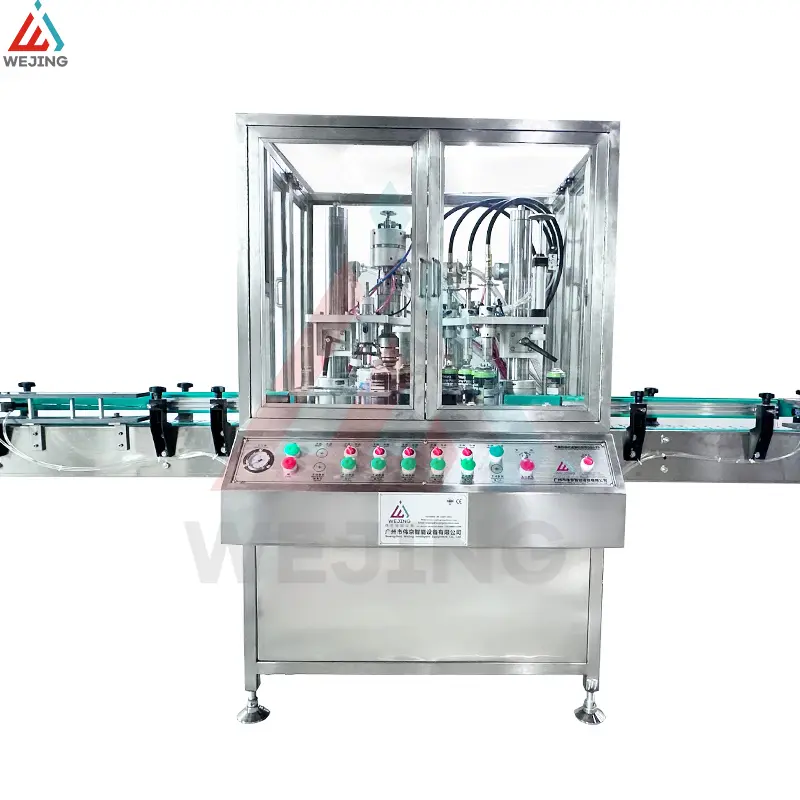

III. Homogenization: Microsizing and Uniformizing Dispersed Substances

Now, let's shift our focus to homogenization. Homogenization is the process of making the dispersed substances in a suspension or emulsion extremely fine and uniform. It's like giving them a makeover at a microscopic level. This is mainly achieved through homogenizers, which are vital in industries like food, dairy, and beverage. In dairy production, for instance, homogenizers break down the fat in milk into smaller particles, thus enhancing the stability of the entire product system. Homogenizers can be classified into two types based on the energy source and mechanism: rotary and pressure type.

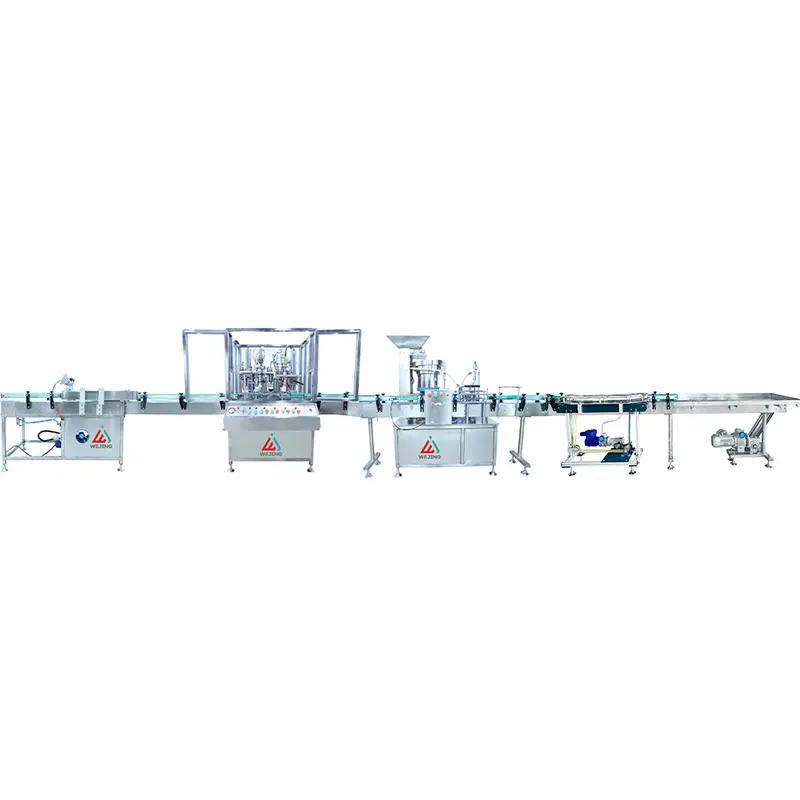

IV. Factors to Consider When Choosing a Homogenizer

When choosing a homogenizer, there are key aspects to consider. The minimum trial quantity matters; a smaller quantity is preferred as it saves materials. The homogeneous pressure is another crucial factor. While higher pressure generally leads to smaller processed particle sizes for most materials, it's not always the case. Some materials might agglomerate under high pressure. The desired processing effect is to achieve a nanometer level of material dispersion and even distribution. Also, the equipment structure plays a role. A homogenizer typically consists of a frame, motor, reducer, mixing shaft, and agitator. Depending on the specific usage scenarios, different forms of agitators and mixing shafts, such as push type, propeller type, and anchor type, can be selected. Some homogenizers even come with special features like explosion-proof and anti-corrosion capabilities, which should be chosen according to the actual needs.

V. Conclusion: The Significance of Understanding These Processes

In conclusion, understanding the differences between homogenization and emulsification, along with the factors involved in choosing the appropriate equipment and agents, is essential for industries relying on these processes to produce high-quality products. Whether it's creating a smooth and stable emulsion for a cosmetic cream or ensuring the uniform distribution of components in a food product, getting these techniques right can make all the difference.