How to Choose an Aerosol Filling Machine Suitable for Your Business

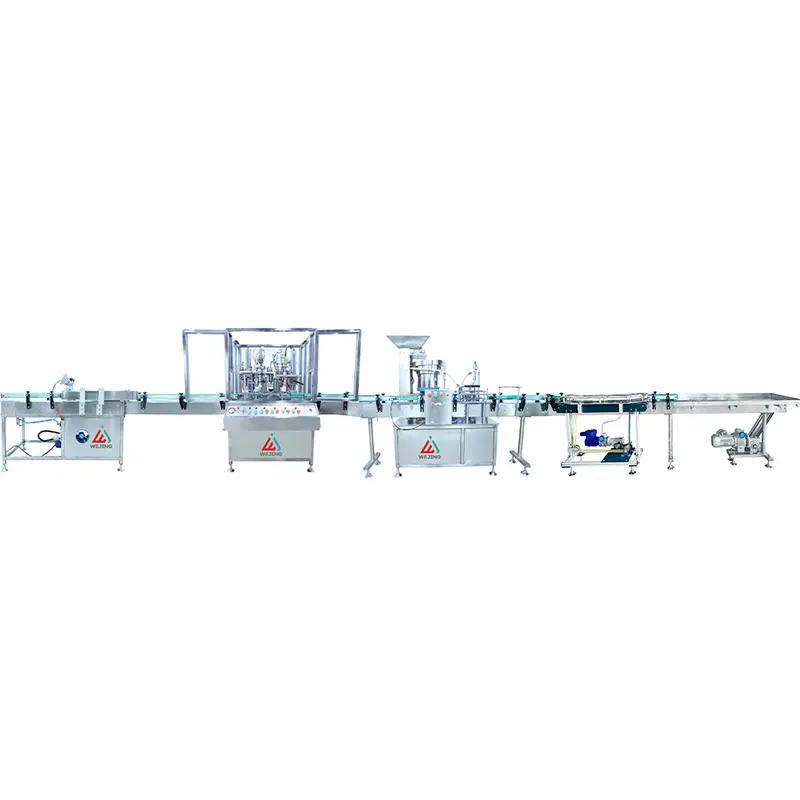

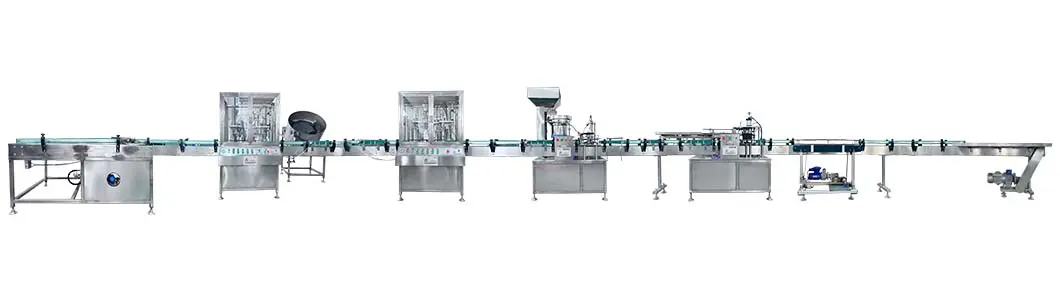

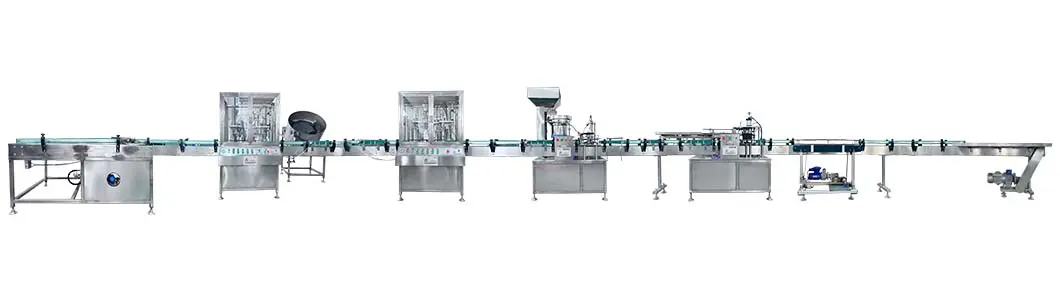

The scale of production directly determines the type of aerosol filling machine required. If you are a start-up enterprise or in small-scale production, equipment like the semi-automatic 3-in-1 pneumatic air freshener aerosol filler gas aerosol can filling crimping machine is a good option. It can handle a certain number of aerosol cans per hour, and the operation is relatively flexible, suitable for small-batch and multi-variety production models, such as the filling of small air fresheners and automotive care aerosols. If your enterprise has developed and has large-scale production needs, such as large daily chemical enterprises, then the automatic aerosol spray filling capping machine is more suitable. It has high-speed and stable filling and capping capabilities, can handle a large number of aerosol cans in a short time, greatly improving production efficiency and reducing unit costs.

Different products have different characteristics, and it is necessary to ensure that the filling machine is compatible with them. For liquid aerosol spray products such as perfumes and air fresheners, the aerosol spray filling crimping machine is the ideal choice. Its advanced filling system can accurately control the liquid flow rate to ensure filling accuracy, and the special crimping process can ensure good sealing of the can mouth. If producing aerosol bag-on-valve products such as nasal sprays and pharmaceutical aerosols, the aerosol bag-on-valve filling machine has more advantages. It can gently and accurately fill the product into the bag valve, effectively protecting the structure of the bag valve and ensuring product quality and usability.

3. Filling Accuracy and Precision

Accurate filling is the key to ensuring product quality. For example, the QGJ70 aerosol filling machine production adopts advanced metering technology, which can accurately control the filling volume of aerosol. Whether it is gas, liquid or two-phase mixed aerosol products, it can ensure that the filling volume error of each can is extremely small. During the filling process, its high-precision valve system can accurately control the in and out of materials to ensure the consistency and accuracy of filling. At the same time, the equipment is equipped with an intelligent monitoring system, which can detect various parameters in the filling process in real time. Once an abnormality is found, it will alarm and adjust in time to ensure stable and reliable product quality. This high-precision filling machine is especially suitable for industries with extremely high requirements for filling accuracy, such as pharmaceutical aerosols and high-end cosmetic aerosols, helping enterprises strictly control product quality and enhance market competitiveness.

4. Ease of Use and Maintenance

An easy-to-operate and maintain filling machine can reduce operating costs. The semi-automatic bag-on-valve aerosol filling machine with a cleaning function has a filling part with a detachable design, which is convenient for quick cleaning after production and avoids residual pollution in the next production. The mechanical structure is simple, and only routine lubrication and component inspection are required for daily maintenance, reducing the technical requirements for operators, saving maintenance time and costs, and helping enterprises achieve long-term stable production.The development of enterprises and market changes require the filling machine to have flexibility. The customized bag-on-valve semi-automatic aerosol liquid filling machine can be customized according to the specific needs of enterprises, such as adapting to different can sizes and different product viscosities. Whether it is a newly launched product or a special specification aerosol can, accurate filling can be achieved by adjusting parameters, helping enterprises respond quickly to the market and maintain competitiveness. Costs not only include the purchase price but also cover maintenance, energy consumption and downtime costs. Some low-priced filling machines may have frequent failures, high energy consumption and complex maintenance although the initial investment is low, and the total cost may be higher in the long run. However, well-known brand filling machines such as those of Weijing Machinery, although relatively expensive, have reliable quality, stable performance, low energy consumption, and the manufacturer provides high-quality after-sales service, reducing downtime and being more cost-effective in the long term. Choosing a reputable manufacturer is of great importance. Weijing Intelligent Equipment Co., Ltd. has been deeply involved in the mixing and filling fields for more than ten years and has rich experience. Its filling machines are made of high-quality materials and advanced technology, strictly following international quality standards and with excellent performance. The praise and long-term cooperation of many customers prove the reliability and stability of its products, which can provide strong production support for enterprises.

Compliance with safety and regulatory requirements is the cornerstone of enterprise operation. Aerosol filling machines that meet relevant standards, such as those meeting GMP standards, fully consider the special requirements of pharmaceutical production in the design and manufacturing process, strictly control the material selection and process flow to ensure the safety, effectiveness and stability of pharmaceuticals during the filling process, providing a solid guarantee for pharmaceutical aerosol production enterprises.

By comprehensively considering the above factors, enterprises can make a wise decision when choosing an aerosol filling machine to ensure efficient production, high-quality products and sustainable development.

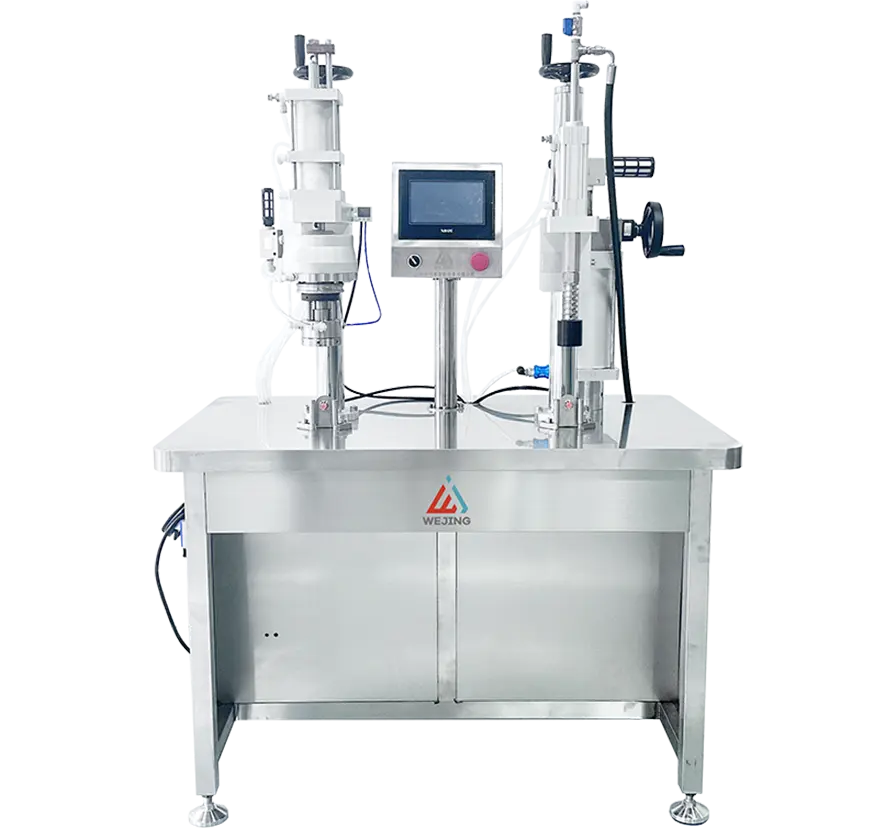

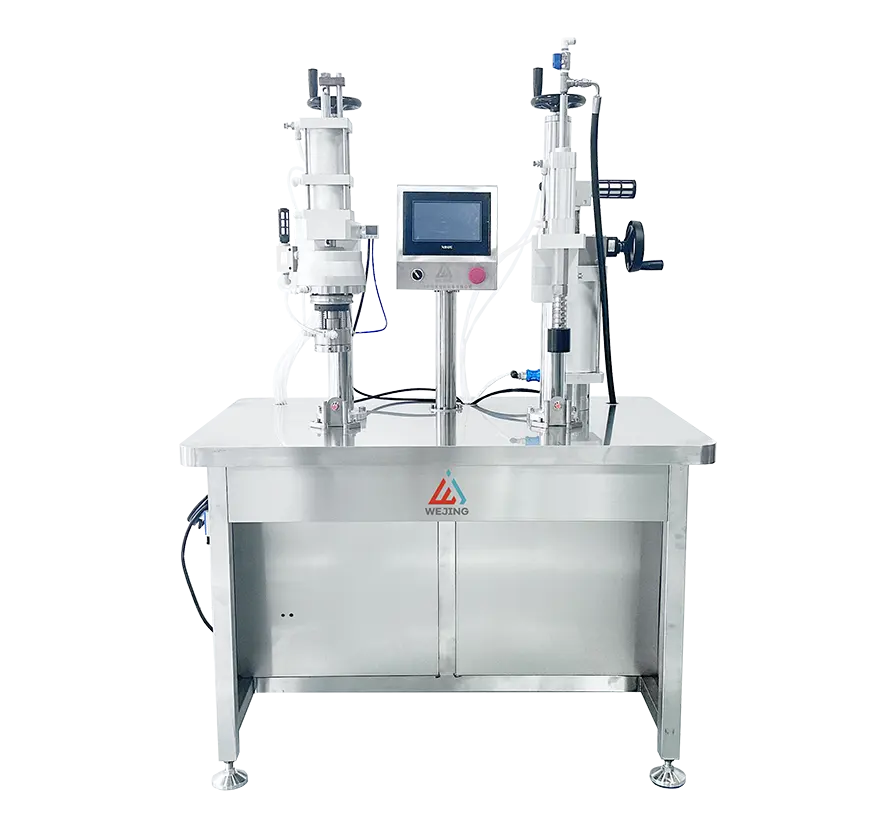

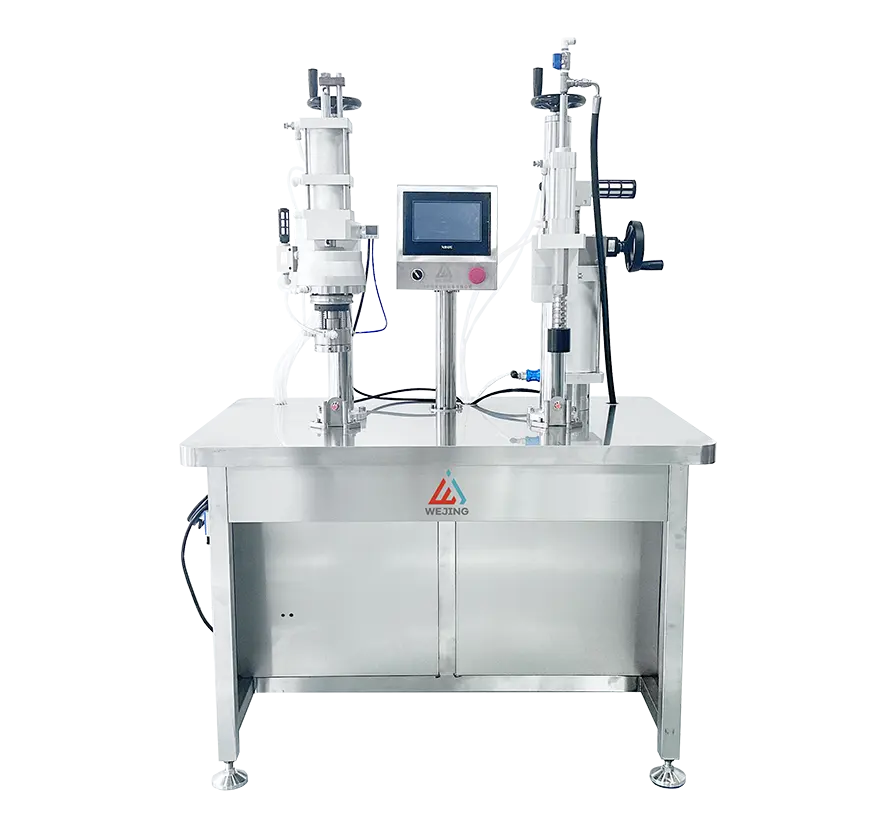

1. Semi-automatic 3-in-1 Pneumatic Air Freshener Aerosol Filler Gas Aerosol Can Filling Crimping Machine

- Function Features: It integrates filling, gas filling and capping functions, adopts pneumatic drive and is easy to operate. It can adapt to various specifications of aerosol cans and is suitable for small-batch production of air fresheners, automotive care aerosols and other products. It has relatively high filling accuracy and can effectively control the filling volume of products to reduce waste.

- Applicable Scenarios: It is suitable for small enterprises or the initial stage of entrepreneurship, where there are high requirements for production flexibility, a variety of products and small production scale. For example, a small daily chemical factory producing different scented air fresheners can quickly adjust production according to order requirements.

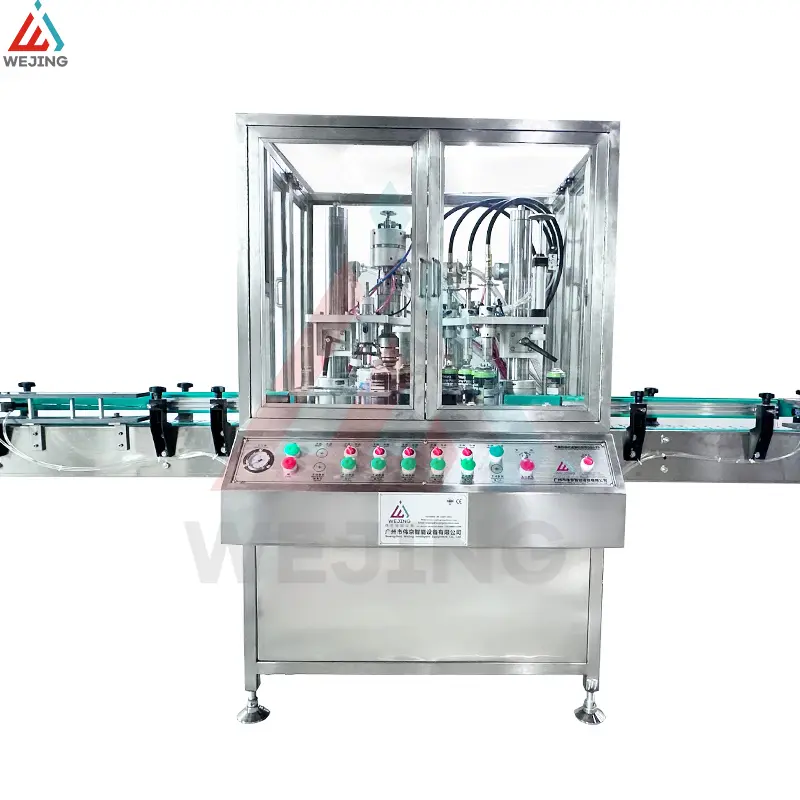

2. Aerosol Spray Filling Crimping Machine (for Liquid Aerosol Spray Products)

- Function Features: It is specially designed for the filling and crimping sealing of liquid aerosol products. It has an accurate liquid flow control system, which can ensure the accurate and consistent filling volume of each can. The crimping process is advanced and can ensure tight sealing of the can mouth to prevent liquid leakage. At the same time, the cleaning and maintenance of the equipment are relatively convenient, which can effectively improve production efficiency.

- Applicable Scenarios: It is widely used in the production enterprises of liquid aerosol products such as perfumes, air fresheners and cleaning sprays. For example, in the perfume production line of a large daily chemical enterprise, with extremely high requirements for filling accuracy and sealing, this equipment can meet its large-scale and high-quality production needs.

3. Aerosol Bag-on-Valve Filling Machine (for Aerosol Bag-on-Valve Products)

- Function Features: It is optimized for the structure of the aerosol bag-on-valve, adopts a special filling device, which can gently and accurately fill the product into the bag valve without damaging the bag valve. It is equipped with an advanced detection system, which can monitor various parameters in the filling process in real time to ensure stable product quality. In addition, the operation interface of the equipment is user-friendly and easy for workers to operate and master.

- Applicable Scenarios: It is suitable for fields with strict requirements for product quality and packaging, such as nasal sprays, pharmaceutical aerosols and some high-end cosmetic aerosols. For example, a pharmaceutical enterprise producing nasal sprays needs to ensure the accurate filling of drugs and the integrity of the bag valve, and this filling machine can provide a reliable solution.

4. QGJ70 Aerosol Filling Machine Production

- Function Features: It adopts advanced metering technology to ensure high-precision control of the filling volume of aerosol. Whether it is gas, liquid or two-phase mixed aerosol products, it can be accurately filled. The high-precision valve system ensures the accurate control of the in and out of materials and realizes the consistency of filling. The intelligent monitoring system detects the filling parameters in real time, and alarms and adjusts in time when abnormalities are found to ensure stable product quality. The equipment has a compact and reasonable structure, which is convenient for installation and operation and can effectively improve production efficiency.

- Applicable Scenarios: It is widely used in industries with extremely high requirements for filling accuracy, such as pharmaceutical aerosols and high-end cosmetic aerosols. For example, in a pharmaceutical enterprise producing pharmaceutical aerosols, strict filling accuracy requirements ensure the accurate dosage of drugs and the curative effect; in a high-end cosmetic enterprise producing fine spray products, this filling machine can ensure the high quality and stability of products.

5. Semi-automatic Bag-on-Valve Aerosol Filling Machine with Cleaning Function

- Function Features: In addition to the basic filling and capping functions, its outstanding feature is the cleaning function. The filling part has a detachable design, which is convenient for quick cleaning after production and effectively prevents residual products from polluting the next production. The cleaning system of the equipment is reasonably designed and can perform in-depth cleaning of key parts to ensure that the hygienic condition of the equipment meets the production standards. At the same time, the operation of this filling machine is also relatively simple, reducing the technical requirements for operators.

- Applicable Scenarios: It is suitable for aerosol production enterprises with high requirements for product hygiene, such as food aerosols, pharmaceutical aerosols and infant care aerosols. In the production of food aerosols, such as the filling of cooking spray oil, the cleaning function of the equipment can ensure the safety and quality of products and avoid cross-contamination.

6. Customized Bag-on-Valve Semi-automatic Aerosol Liquid Filling Machine

- Function Features: Its greatest advantage is its high degree of customization. It can be customized according to the specific needs of customers, such as different filling volumes, filling speeds and filling accuracies, to meet the requirements of various special products and production processes. The equipment adopts a modular design, which is convenient for function expansion and upgrading, and can be flexibly adjusted with the development of enterprises and market changes. At the same time, under the premise of ensuring customized functions, it still maintains high stability and reliability.

- Applicable Scenarios: It is suitable for enterprises with special product requirements or those that need to frequently adjust production processes. For example, when a new cosmetic brand launches personalized packaged and formulated aerosol products, or a scientific research institution conducts small-scale experimental production, this filling machine can be customized according to its unique requirements to meet diverse production needs.