Innovation Driven Growth in Bag On Valve Aerosol Filling Machine Market

Technical Innovations of BOV Filling Systems

Market Growth and Regional Characteristics

New Applications Expanding the Market

Although pharmaceuticals and cosmetics are still the main sectors using BOV technology, it is now entering new markets. In the food and beverage industry, nitrogen-propelled BOV systems are used to keep liquid and semi-solid products fresh. In the industrial field, anti-corrosion sprays and lubricants benefit from the precise and residue-free dispensing of BOV technology. In healthcare, Aptar's PureHale portable nebulizer shows the potential of BOV in respiratory care innovation.

Manufacturing Breakthroughs in China

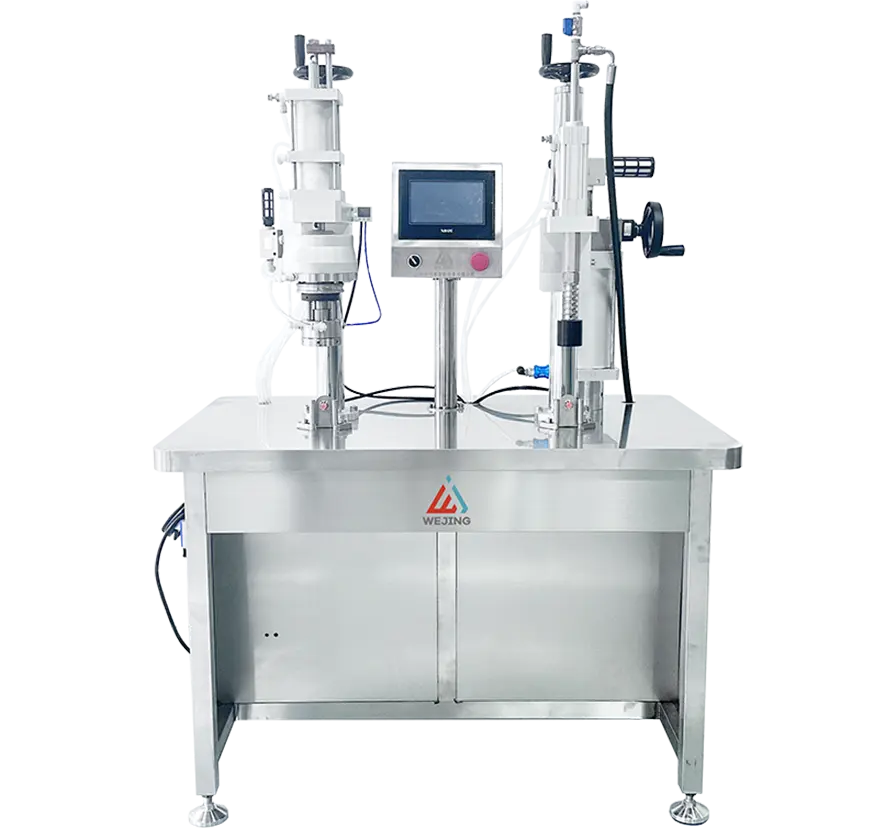

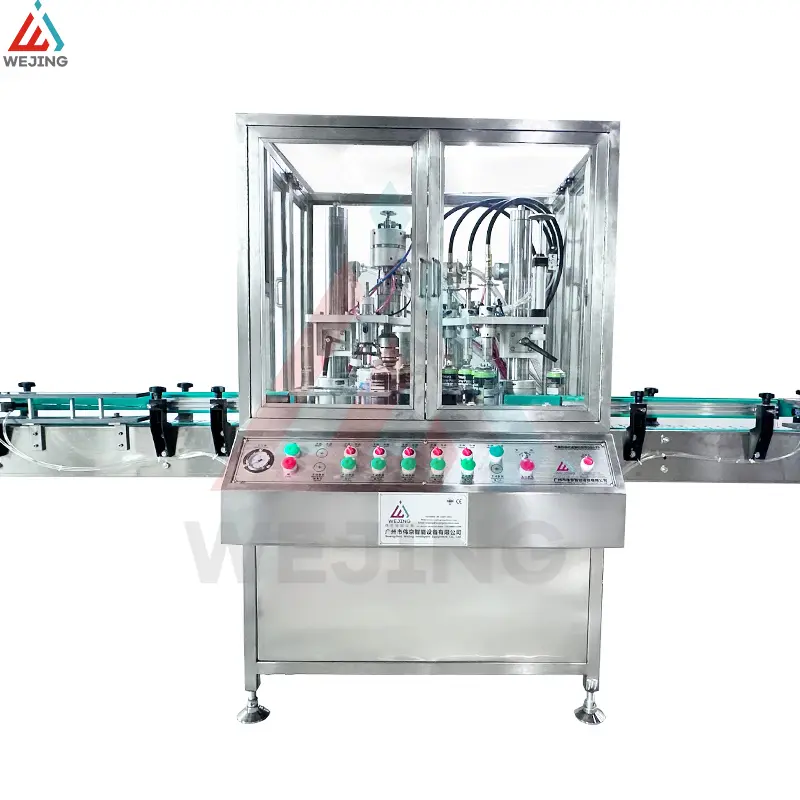

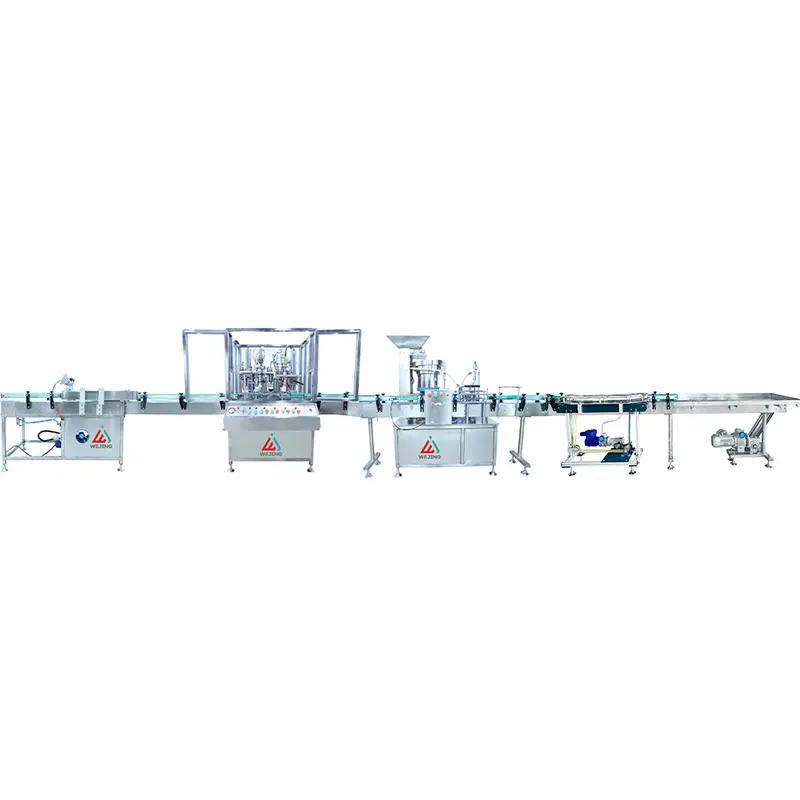

Chinese manufacturers are making significant contributions to BOV machinery. Wuhan Fillertech's automated production lines can achieve high speeds, filling, sealing, and conducting quality checks efficiently at a rate of 6 - 35 bags per minute. Guangzhou Aile's Bag-on-Valve filling machine offers advanced features at a reasonable price, enhancing its market competitiveness. Additionally, Chinese manufacturers are also focusing on sustainability, with recycling-compatible designs to reduce waste during production.

Future Outlook: AI - Powered Advancements

The future of BOV technology looks promising with the integration of AI and robotics. According to TrendForce, by 2025, AI - driven automation is expected to optimize the filling process, reducing errors by 30%. The growing demand for personalized packaging, such as customizable actuator colors, and circular economy - compliant designs will also fuel further research and development in this field.

Conclusion

The BOV aerosol filling machine market is on the verge of significant growth. Driven by technological progress, regional manufacturing strengths, and its expansion into various industries, this market offers numerous opportunities. As sustainability and smart manufacturing become more important, companies need to keep innovating to stay ahead in this competitive market.