News Categories

Featured News

010203

Moisturizing Cosmetics: Industry Trends & Equipment Demands

2024-12-24

In the sweltering summer, the sun beats down mercilessly. As the height of summer arrives, the temperature soars. At the same time, the intense sunlight can put a strain on the skin, leading to issues like dehydration and dryness. Moisturizing products, however, can offer a certain degree of protection to the skin. Using moisturizers in summer is of great significance as it acts as a crucial safeguard for our skin.

The Industry Development Trend of Moisturizing Cosmetics

As a burgeoning industry, the moisturizing cosmetics sector is advancing at a rapid pace. With the growth of the social economy, people are placing increasing emphasis on the health and care of their skin, and the sales of moisturizing products are on the rise year after year. The development of the moisturizing cosmetics market is influenced by a multitude of factors, with the enhancement of consumers' quality requirements and the transformation of consumption concepts being the most prominent. Nowadays, people are more and more concerned about skin protection and are paying closer attention to the quality of moisturizing products. The demands for moisturizing ingredients, natural component ratios, and efficacy levels are also becoming higher and higher.

In addition, the development of the moisturizing cosmetics industry has also received strong support from the government. The government has implemented various measures to promote the growth of the industry, such as introducing support policies and providing consumer subsidies. These government initiatives help to boost consumers' confidence in products and drive the development of the industry. With the progress of the moisturizing cosmetics industry, the moisturizing products available on the market are becoming increasingly diverse. Some renowned brands have launched a variety of new moisturizing products, such as intensive hydrating creams, water-light moisturizing gels, and alcohol-free moisturizing sprays, offering consumers more choices.

The moisturizing cosmetics industry is continuously expanding, and the market is presented with greater development opportunities. It is anticipated that in the coming years, with the support of government policies and consumers' growing focus on moisturization, the market size of the moisturizing cosmetics industry will continue to expand rapidly.

In short, as consumers pay more and more attention to moisturization and with the backing of government policies, the market scale of the moisturizing cosmetics industry will further enlarge, and the market prospects will be extremely promising.

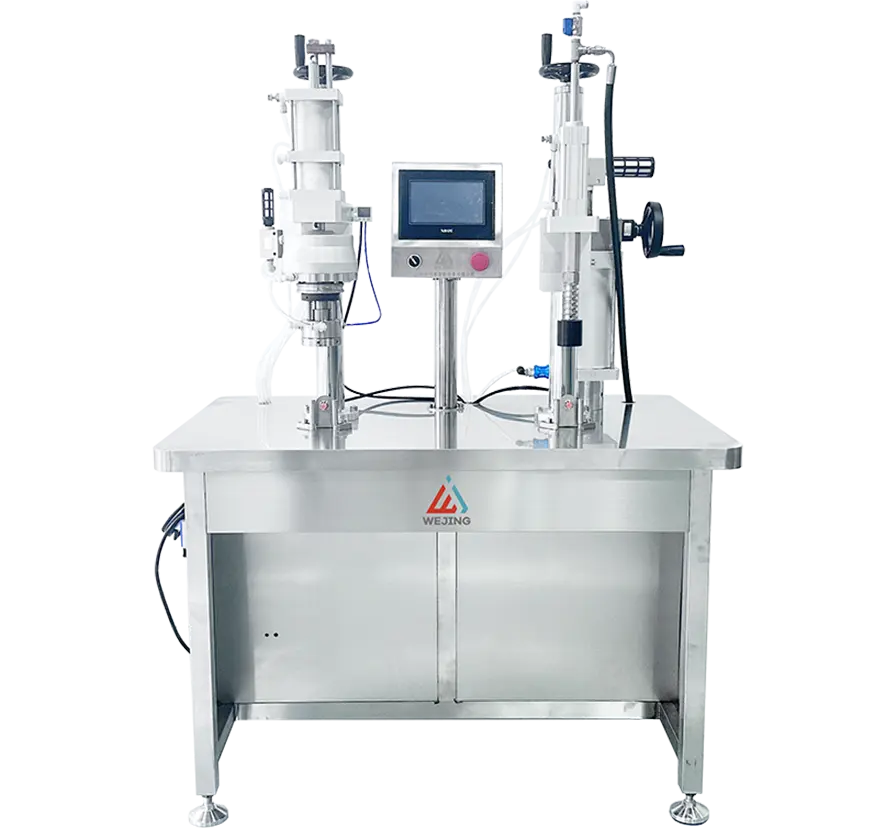

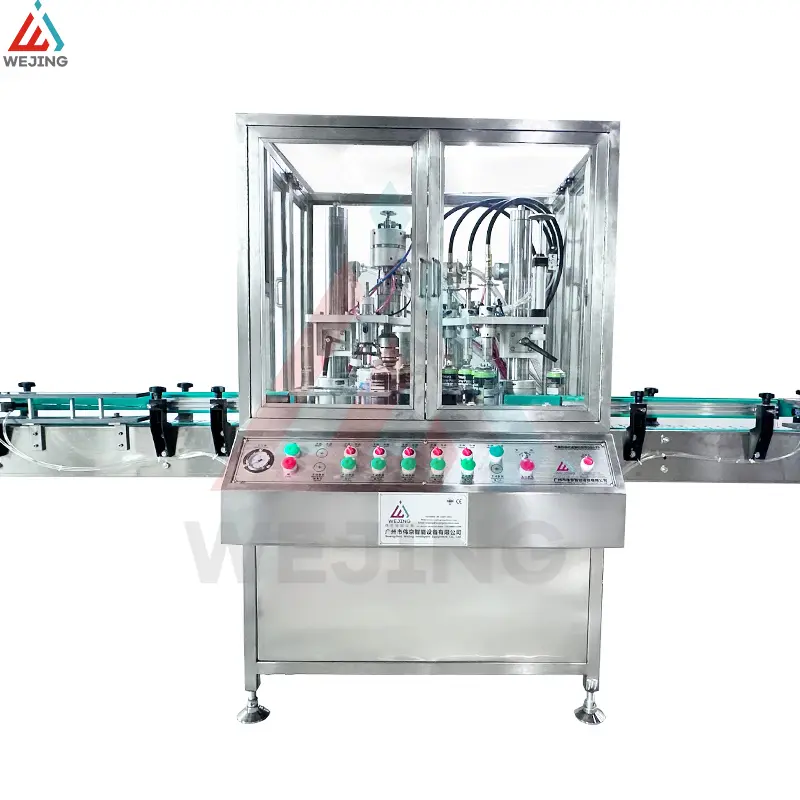

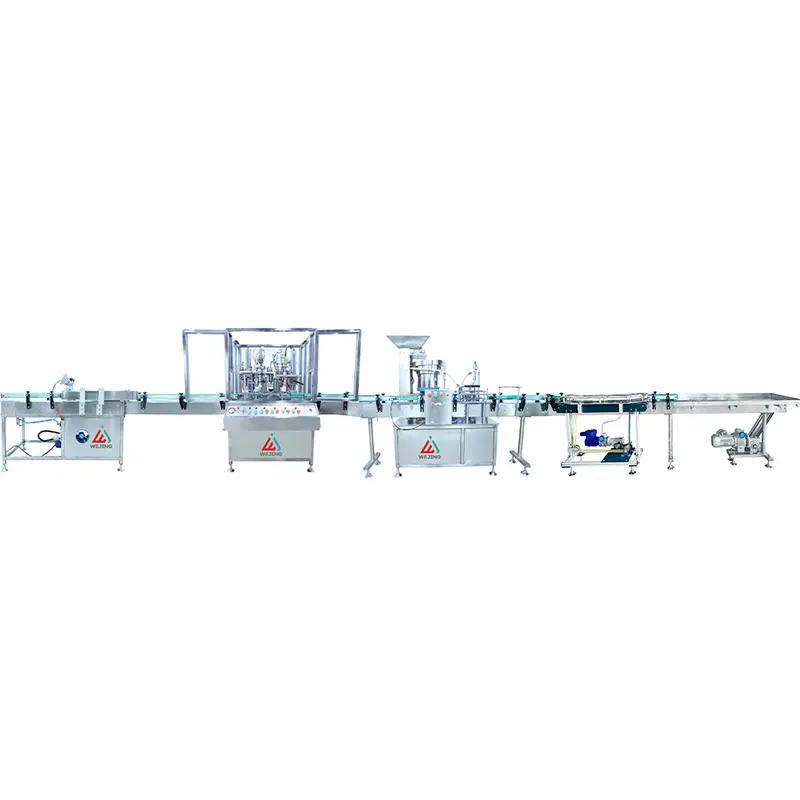

The Demand for Moisturizing Production Equipment

Emulsifier mixer equipment is specialized machinery for producing emulsified products, especially moisturizers. In the industry, the high shear emulsifier mixer and the vaccum emulsifier mixer are very important types. After learning about the emulsifier mixer, perhaps one can envision its functions. The emulsifier mixer is closely related to our daily lives, and its presence has made life more convenient.

As people's demand for emulsified products continues to increase, the development prospects of emulsifier mixer equipment will become broader. In the future, emulsifier mixer equipment will be more efficient, intelligent, energy-efficient, and environmentally friendly. To meet the market needs, emulsifier mixer equipment manufacturers will continuously improve the technology and processes of the equipment, enhancing the production efficiency and product quality of the equipment. At the same time, the emulsifier mixer equipment will become increasingly intelligent, achieving automatic control and online monitoring, and improving the controllability and stability of the production process.

As a manufacturer of moisturizing cosmetic equipment, Wejing Machinery is a professional emulsifier mixer manufacturer with more than 10 years of production experience. It is actively exploring and conducting rigorous tests during the design and manufacturing of equipment, comprehensively analyzing all aspects of the product to ensure that the moisturizing production equipment delivered to the market can bring greater benefits to enterprises.

Here are some recommendations for the Wenjing Emulsifier Mixer

1. 300L Chemical Body Lotion Emulsifier Manufacturing Machine - Vacuum Homogenizing Emulsifier

- Features:

- It has a large capacity of 300L, suitable for medium to large-scale production of emulsified products.

- The vacuum homogenizing function can effectively remove air bubbles, making the emulsification more uniform and fine, and improving product quality.

- Applicable Range: Applicable to the production of various products with high emulsification effect requirements such as chemical body lotions.

2. 50L Liquid Soap and Cosmetics Emulsifying High Shear Mixing Homogenizing Machine Equipment

- Features:

- The 50L capacity is moderate and is more suitable for small production enterprises or the product research and development stage.

- The high shear mixing homogenizing function can quickly and evenly mix the raw materials, with high emulsification efficiency.

- Applicable Range: Commonly used in the production of emulsified products such as liquid soaps and cosmetics, especially suitable for products that require rapid emulsification and uniform texture.

3. 10L Emulsifier - High Shear Vacuum Emulsifying Mixing Machine (with Hydraulic Lifting)

- Features:

- The 10L small capacity design is suitable for laboratory research and development or small-batch production.

- The high shear vacuum emulsifying mixing, while ensuring the emulsification effect, is convenient for operation and maintenance through hydraulic lifting.

- Applicable Range: Can be used for the production of small samples or small-batch production of various cosmetics and skin care products, such as the research and development stage of creams and lotions.

4. High Shear Dispersing Cream Body Lotion Ointment Emulsifier

- Features:

- Emphasizes the high shear dispersing function, which can handle relatively thick cream and ointment emulsified products, ensuring the full mixing of raw materials.

- Helps to improve the stability and uniform texture of the product.

- Applicable Range: Mainly applicable to the production of emulsified products such as cream-like and ointment-like body lotions, skin care products, and pharmaceuticals.

5. 300L Hydraulic Lifting Vacuum Homogenizing Emulsifier (with Heating Function)

- Features:

- The 300L capacity meets the production needs of a certain scale.

- The hydraulic lifting facilitates the adjustment of the operating height, the vacuum homogenization ensures the emulsification effect, and the heating function is helpful for the production of some products that require specific temperature conditions for emulsification, such as some cosmetics containing heat-sensitive ingredients.

- Applicable Range: Widely applicable to the production of various cosmetics, daily chemical products, etc. that require heating-assisted emulsification processes.

These emulsifier mixers play a crucial role in the production of moisturizing cosmetics and other emulsified products, and their development and application are also constantly evolving to meet the increasing demands of the market.

Here are some recommendations for the Wenjing Emulsifier Mixer

1. 300L Chemical Body Lotion Emulsifier Manufacturing Machine - Vacuum Homogenizing Emulsifier

- Features:

- It has a large capacity of 300L, suitable for medium to large-scale production of emulsified products.

- The vacuum homogenizing function can effectively remove air bubbles, making the emulsification more uniform and fine, and improving product quality.

- Applicable Range: Applicable to the production of various products with high emulsification effect requirements such as chemical body lotions.

2. 50L Liquid Soap and Cosmetics Emulsifying High Shear Mixing Homogenizing Machine Equipment

- Features:

- The 50L capacity is moderate and is more suitable for small production enterprises or the product research and development stage.

- The high shear mixing homogenizing function can quickly and evenly mix the raw materials, with high emulsification efficiency.

- Applicable Range: Commonly used in the production of emulsified products such as liquid soaps and cosmetics, especially suitable for products that require rapid emulsification and uniform texture.

3. 10L Emulsifier - High Shear Vacuum Emulsifying Mixing Machine (with Hydraulic Lifting)

- Features:

- The 10L small capacity design is suitable for laboratory research and development or small-batch production.

- The high shear vacuum emulsifying mixing, while ensuring the emulsification effect, is convenient for operation and maintenance through hydraulic lifting.

- Applicable Range: Can be used for the production of small samples or small-batch production of various cosmetics and skin care products, such as the research and development stage of creams and lotions.

4. High Shear Dispersing Cream Body Lotion Ointment Emulsifier

- Features:

- Emphasizes the high shear dispersing function, which can handle relatively thick cream and ointment emulsified products, ensuring the full mixing of raw materials.

- Helps to improve the stability and uniform texture of the product.

- Applicable Range: Mainly applicable to the production of emulsified products such as cream-like and ointment-like body lotions, skin care products, and pharmaceuticals.

5. 300L Hydraulic Lifting Vacuum Homogenizing Emulsifier (with Heating Function)

- Features:

- The 300L capacity meets the production needs of a certain scale.

- The hydraulic lifting facilitates the adjustment of the operating height, the vacuum homogenization ensures the emulsification effect, and the heating function is helpful for the production of some products that require specific temperature conditions for emulsification, such as some cosmetics containing heat-sensitive ingredients.

- Applicable Range: Widely applicable to the production of various cosmetics, daily chemical products, etc. that require heating-assisted emulsification processes.

These emulsifier mixers play a crucial role in the production of moisturizing cosmetics and other emulsified products, and their development and application are also constantly evolving to meet the increasing demands of the market.