What is Vacuum Emulsifier Mixer?

2024-11-14

Introduction

This article provides a comprehensive overview of vacuum emulsifier mixers. Vacuum emulsifier mixers are essential devices in various industries, playing a crucial role in the production of emulsified products.

2. Definition of Vacuum Emulsifier Mixer

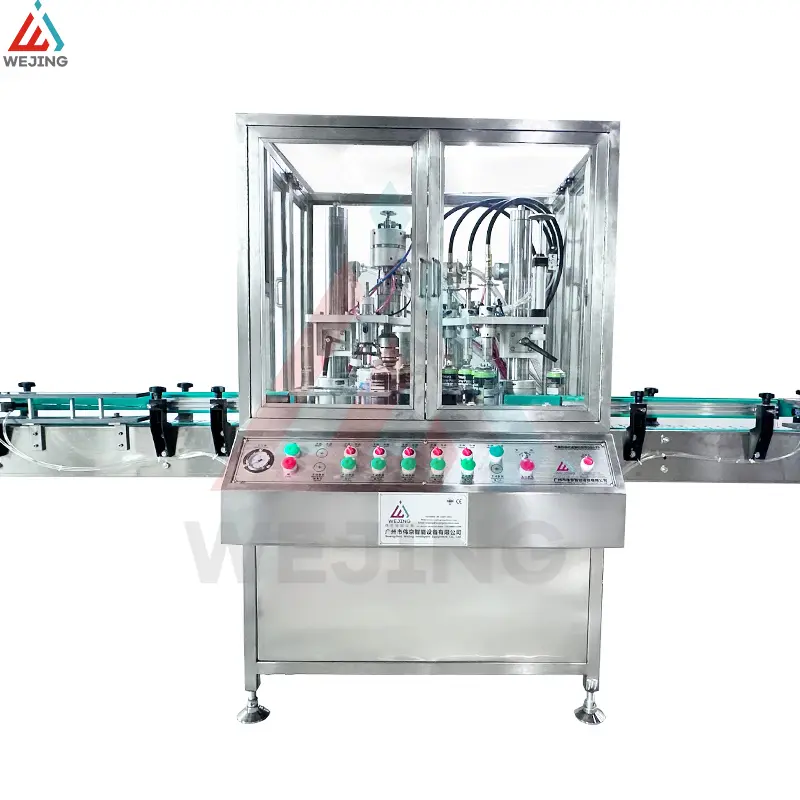

A vacuum emulsifier mixer is a sophisticated piece of equipment that operates under vacuum conditions. It employs a high shear emulsifier to rapidly and evenly distribute one or several phases into another continuous phase. The materials are processed in the narrow space between the stator and rotor, generating intense mechanical energy. Through hydraulic shearing, centrifugal extruding, impacting, breaking, and turbulence occurring over 100 thousand times per minute, the materials are instantly and evenly dispersed and emulsified. This results in a fine, stable, and high-quality product free of bubbles.

3. Classification of Vacuum Emulsifier Mixers

3.1 Based on Homogenizing Systems

Upper Homogenization: This homogenizing system offers a specific emulsifying effect. Suited for applications where a particular emulsion formation is required. For instance, in certain cosmetic formulations, it can achieve the desired texture and stability.

Lower Homogenization: Provides an alternative emulsifying approach. Used when different emulsifying characteristics are needed. In food production, like making salad dressings, it ensures proper ingredient mixing and a stable emulsion.

Internal and External Circulating Homogenization: Combines the advantages of both internal and external circulation for a more thorough emulsification process. In the pharmaceutical industry, it helps in producing creams and ointments with consistent quality.

3.2 Based on Mixing Systems

Single-Way Mixing: A simpler form of mixing suitable for less complex emulsification processes. Economical and efficient for basic cosmetic products or food items with straightforward formulations.

Double-Way Mixing: Offers a more comprehensive mixing action for applications demanding a higher level of emulsification. Ideal for producing high-quality cosmetics or complex food emulsions.

Helical Ribbon Mixing: Provides a unique mixing pattern beneficial for materials requiring gentle yet thorough mixing. Preferred in industries with sensitive ingredients, such as pharmaceuticals or specialty chemicals.

3.3 Based on Lifting Systems

Single-Cylinder Lifting: Designed for specific applications with certain lifting capacity requirements. Often used in smaller-scale production setups or where space is limited.

Double-Cylinder Lifting: Offers greater lifting capacity, suitable for larger vacuum emulsifier mixers and applications with heavier components. Ensures smooth operation and ease of maintenance in industrial settings with high production volumes.

4. Applications of Vacuum Emulsifier Mixers

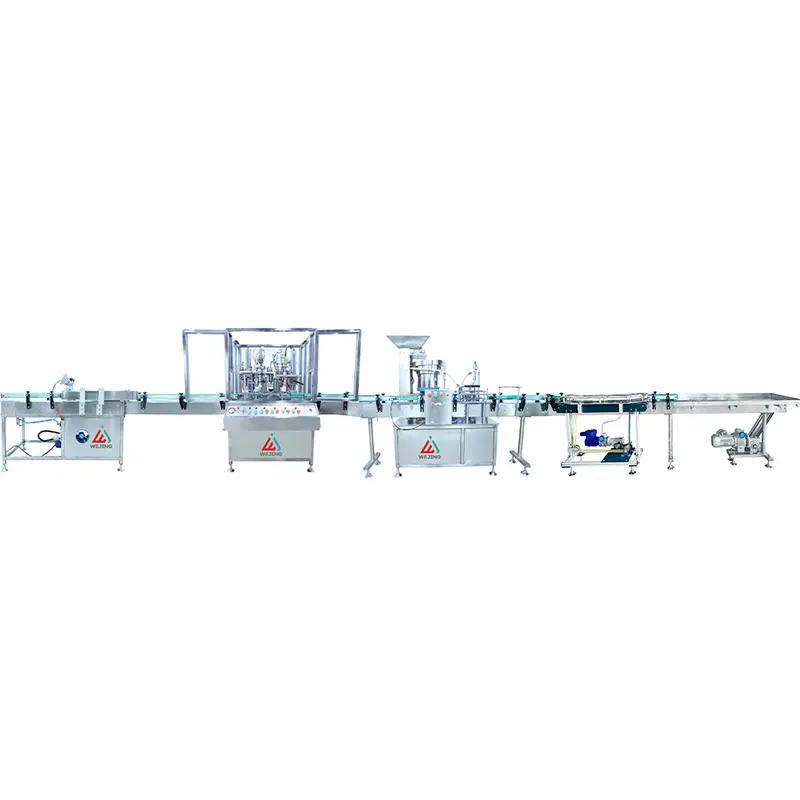

Vacuum emulsifier mixers find extensive applications across multiple industries:

Daily Chemical Care Products: Used in the production of lotions, creams, and other skincare products to achieve a smooth and stable emulsion for a pleasant texture and effective benefits.

Biopharmaceutical Industry: Essential for producing pharmaceutical creams, ointments, and some liquid formulations, ensuring proper dispersion of active ingredients and product stability.

Food Industry: Plays a vital role in manufacturing salad dressings, mayonnaise, and dairy products like cream and ice cream, creating a stable emulsion for improved taste and texture.

Paint and Ink Industry: Emulsifies pigments and other components in paint and ink formulations for a more consistent and high-quality product with better color dispersion and stability.

Other Industries: Also applied in the production of nanometer materials, petrochemical products, printing and dyeing auxiliaries, pulp & paper, pesticides, fertilizers, plastics & rubber, electrics and electronics, and fine chemical industry.

5. Conclusion

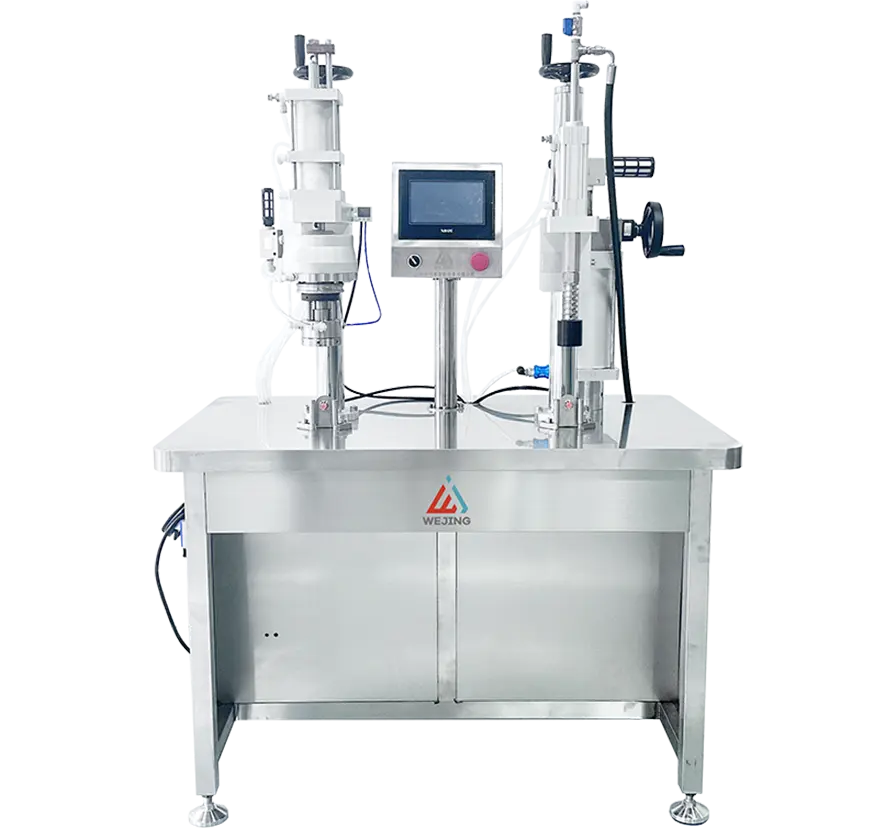

Vacuum emulsifier mixers are indispensable tools in various industries. Their ability to create stable emulsions under vacuum conditions and the diverse classification options make them highly versatile. When it comes to choosing a vacuum emulsifier mixer, look no further than Wejing. Our vacuum emulsifier mixers are designed with precision and quality in mind. We offer a wide range of models to meet different production requirements. With advanced technology and reliable performance, Wejing vacuum emulsifier mixers ensure efficient production and high-quality products. Choose Wejing for your emulsification needs and experience the difference in quality and service.